Across North America, fabricators rely on MetalForming for world-class technology, nationwide service, and industry expertise that helps them achieve more. From entry-level equipment for growing shops to advanced, high-performance systems for large-scale architectural projects, MetalForming provides solutions that match every need.

For almost 30 years, MetalForming has delivered innovation, reliability, and service excellence to the metal fabrication industry. Our portfolio includes a comprehensive range of architectural machines designed to enhance precision, speed, and safety while giving fabricators the confidence to take on any challenge.

A Legacy of Partnership and Progress

Founded in 1997, MetalForming has grown into North America’s largest distributor of sheet metal processing machines. Our success is built on a philosophy of partnership by helping customers through every stage of the equipment lifecycle. From consultation and installation to training and ongoing production support, MetalForming provides a complete service experience.

Solutions for Every Fabricator

Our product offering includes folding machines, shears, rollforming systems, and coil processing equipment. Each piece of equipment is carefully chosen for its ability to help fabricators improve efficiency, reduce waste, and produce consistent, high-quality results.

MetalForming’s partners include the most respected names in fabrication in the world: Schroeder, Schechtl, Jorns, Schlebach, Stolarczyk, and VIETSTEEL. These global manufacturers share a commitment to precision engineering and long-term reliability. Together, they represent the best in modern metal forming technology.

Schroeder: Precision Engineering for Architectural Fabricators

For more than 50 years, Schroeder has been synonymous with German precision and innovation. Its machines are designed for fabricators who demand exact results and reliable performance day after day. MetalForming is proud to bring Schroeder’s latest architectural solutions to North America.

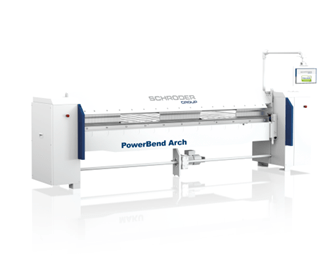

Schroeder PowerBend Architectural (PBA) Folding Machine

The PowerBend Architectural (PBA) is engineered for fabricators who need speed, precision, and safety in one system. It expands Schroeder’s proven technology into the architectural sector, allowing shops to form large panels and intricate geometries with remarkable consistency.

Key features include:

- 126-inch working length for large-format panels

- Fiessler laser safety system for advanced operator protection

- Simplified tool changes that reduce downtime

- Mechanical clamping beam with a 6-inch stroke for safe, efficient operation

- Radius bending and conical gauging for complex shapes

- POS 2000 Professional control with intuitive operation

- Remote maintenance and diagnostics for maximum uptime

The PBA allows operators to complete complex bends in a single workflow while maintaining production speed. Its intuitive control system, robust construction, and integrated safety features make it a must-have for high-performance fabrication.

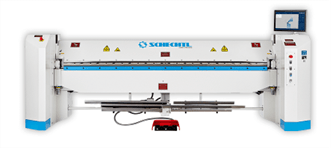

Schroeder MHSU Shear

Paired with the PBA, the MHSU Shear completes the forming workflow. This precision-engineered shear delivers clean, accurate cuts with a strong focus on safety and productivity.

Key features include:

- Classic Cut touch panel for simplified programming

- Front and rear unloading for flexible material handling

- CE-certified three-beam light barrier for operator safety

- Optional ergonomic stacking cart for improved efficiency

- Seamless integration with the PBA folder

The MHSU shear enhances workflow efficiency by allowing shops to transition seamlessly from cutting to folding. Together, the PBA and MHSU create a reliable system for architectural fabricators producing panels, roofing, and other custom components.

Schroeder PowerBend Multi (PBM)

For shops that require an all-around performer, the PowerBend Multi is a versatile solution designed for thin sheet metal processing. It combines flexibility with precision and is ideal for fabricators who manage a variety of project types.

The PowerBend Multi features a rotating clamping beam that can be equipped with tools of different heights up to 170 mm, allowing for fast transitions between tool setups. With up to 160 mm of upper beam stroke and a folding beam that moves to the back, it accommodates complex workpieces with ease. Central crowning ensures a straight bend across the full working length, even with thicker materials.

Available in lengths of 2 520 mm, 3 220 mm, or 4 020 mm, the PowerBend Multi provides several back gauge options and can be configured to suit specific shop requirements. It offers the precision and power needed for demanding architectural fabrication.

VIETSTEEL Delivers High-Speed Rollforming for the Modern Fabricator

VIETSTEEL brings a new level of efficiency to North American fabrication. Known worldwide for its high-speed rollforming equipment, the company offers roofing, purlin, and floor deck machines that combine consistency, and customization.

Available in single- and double-deck models, VIETSTEEL systems help fabricators increase output without compromising quality. Each machine is engineered for high-speed operation and minimal downtime.

Key advantages include:

- High precision and consistent product quality

- Efficient high-speed production

- Flexible design with custom profiles available

- Durability for long-term reliability

- Short, predictable delivery times

- Energy-efficient operation

- User-friendly controls for fast setup and operation

With over 3,500 machines installed across 41 countries, VIETSTEEL is a proven global leader. Every system is supported by a one-year warranty and 24/7 after-sales service. Its partnership with MetalForming ensures North American customers receive local expertise and reliable ongoing support.

Smarter Portable Rollforming from New Tech

The New Tech SSQ3 represents the next generation of portable rollforming. Designed for contractors and shop operators who need mobility without compromising performance, the SSQ3 builds on the success of the SSQ II with advanced technology and safety enhancements.

The SSQ3 can run up to 16 different panel profiles, including standing seam, flush wall, and board-and-batten siding. Its high-speed hydraulic drive increases production capacity, while the Quick-Change power pack allows fast transitions between gas and electric power.

Enhanced controls, RFID cover sensors, LED lighting, and a shear warning strobe improve safety and usability. Whether operating in a shop or on a job site, the SSQ3 delivers reliability, flexibility, and exceptional control.

Schlebach: Innovation in Standing Seam Rollforming

The Schlebach Quadro PLUS is the result of collaboration between MetalForming and Schlebach to create one of the most advanced standing seam rollforming systems available. The Quadro PLUS combines flexibility with speed and precision, allowing fabricators to achieve certified, high-performance panels directly from their own facilities.

Its modular cassette design enables fast profile changes and a wide range of configurations. Inline notching and a rotating cassette system deliver maximum versatility and productivity. The result is a system that allows fabricators to meet strict certification standards while maintaining efficiency and adaptability.

Schechtl: Engineered for Everyday Performance

Schechtl machines are known for their precision, durability, and ease of use. They’re a staple in shops across North America and around the world, providing both entry-level and advanced folding capabilities.

Schechtl MAX-F

The MAX-F short folding machine introduces new “F-Geometry,” creating additional free space at the front of the machine for complex folds and deeper profiles. With motor-operated back gauges, CNC touch controls, and a faster servo drive, the MAX-F improves throughput while maintaining precision. It provides the flexibility to bend hat channels, vented ridges, and bigger J’s, and pitch correct drip edges with ease.

Schechtl UKV Handbrake

The UKV Handbrake offers unmatched versatility for single-piece production, small series, and prototype construction. Its segmented tooling allows operators to create a wide variety of shapes, making it an essential tool for custom architectural work. The UKV is ideal for shops looking for precision control in a compact, manual format.

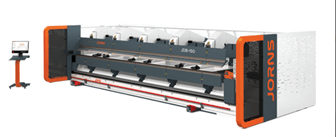

Experience Future-Ready Automation with Jorns

The Jorns Double Bender (JDB) combines automation and accuracy in one robust system. Available in lengths from 13 to 40 feet, the JDB handles materials up to 11-gauge mild steel.

Jorns has been advancing automated bending technology since the 1980s, developing integrated robotic handling systems and Industry 4.0 connectivity through Bendex software. The JDB enables fabricators to produce a wide range of profiles for roofing, wall panels, and architectural designs, including tapered and corrugated components.

Automation through Jorns technology gives shops the capacity to increase throughput, minimize manual handling, and improve repeatability, which are key advantages in competitive architectural markets.

Smart Coil Processing with Stolarczyk

Efficient coil handling and processing form the foundation of every successful fabrication workflow. Stolarczyk offers a family of equipment designed to keep material moving safely and efficiently through production.

Stolarczyk LIL Bob Decoiler

Compact and portable, the LIL Bob Decoiler provides a one-ton capacity and rugged mobility for shops that need flexibility. It can also be mounted for 1.5-ton capacity, making it a versatile solution for smaller operations or tight workspaces.

Stolarczyk Decoiler

For higher capacity needs, the Stolarczyk Decoiler handles coils from five to ten tons with hydraulic expanding operation. It is available with or without a coil cart and includes remote-control operation for ease of handling.

Stolarczyk ST-1250 Slitting-Cutting System

The ST-1250 brings decades of coil processing expertise into a modern, comprehensive slitting and cut-to-length system. Featuring CNC straightening, laser-hardened rolls, and speeds up to 150 feet per minute, it allows fabricators to produce flat sheets and custom parts in-house. The ST-1250 increases control over material flow, improves turnaround times, and enhances profitability through efficient use of resources.

Each Stolarczyk machine is backed by more than 30 years of engineering experience and built for long-term durability. As the exclusive North American distributor, MetalForming provides access to these high-quality systems along with expert service and support.

Nationwide Support from a Trusted Partner

Beyond equipment, MetalForming’s strength lies in its people and commitment to service. The company’s nationwide network of technicians and support staff ensures quick response times and consistent service. Remote diagnostics, in-stock replacement parts, training programs, and on-site assistance help customers maintain optimal productivity.

MetalForming’s consultative approach means that each recommendation is guided by experience and tailored to the customer’s specific goals. Whether upgrading a single machine or outfitting an entire facility, MetalForming provides a level of expertise that protects every investment.

Through ongoing partnerships and technological integration, MetalForming continues to help fabricators modernize their operations and remain competitive in an evolving industry.

Forming the Future Together

MetalForming continues to set the standard for architectural fabrication by combining advanced machinery with comprehensive service. Our lineup brings together Schroeder’s high-performance folding systems, Schechtl’s dependable short folders, Jorns’ automated bending solutions, Schlebach’s innovative standing seam technology, Stolarczyk’s efficient coil processing equipment, and VIETSTEEL’s high-speed rollformers. Every solution represents a step forward in efficiency and precision.

For almost 30 years, MetalForming has helped fabricators grow their capabilities and their confidence. Whether you are building your first shop or expanding an established operation, MetalForming offers the technology, training, and nationwide support to make it happen.

Want to see our machines in action? We’ll be showcasing many of them at the 2026 International Rollforming Expo in Las Vegas. See what we’ll have on display here.

One partner. Trusted expert. Forming success across North America.

MetalForming Overview

METALCON 2025 MetalForming Booth Walkthrough: