Testing of construction products is conducted for everyone’s peace of mind. Once correctly installed, all products are subjected to a multitude of weather-related conditions including temperature changes, moisture and wind. Products face tougher conditions during testing than they will in the field. It’s important to use products that will meet the strictest of standards and is required by the building codes.

Testing, certification provides confidence with custom-formed products

Fabricated Projects

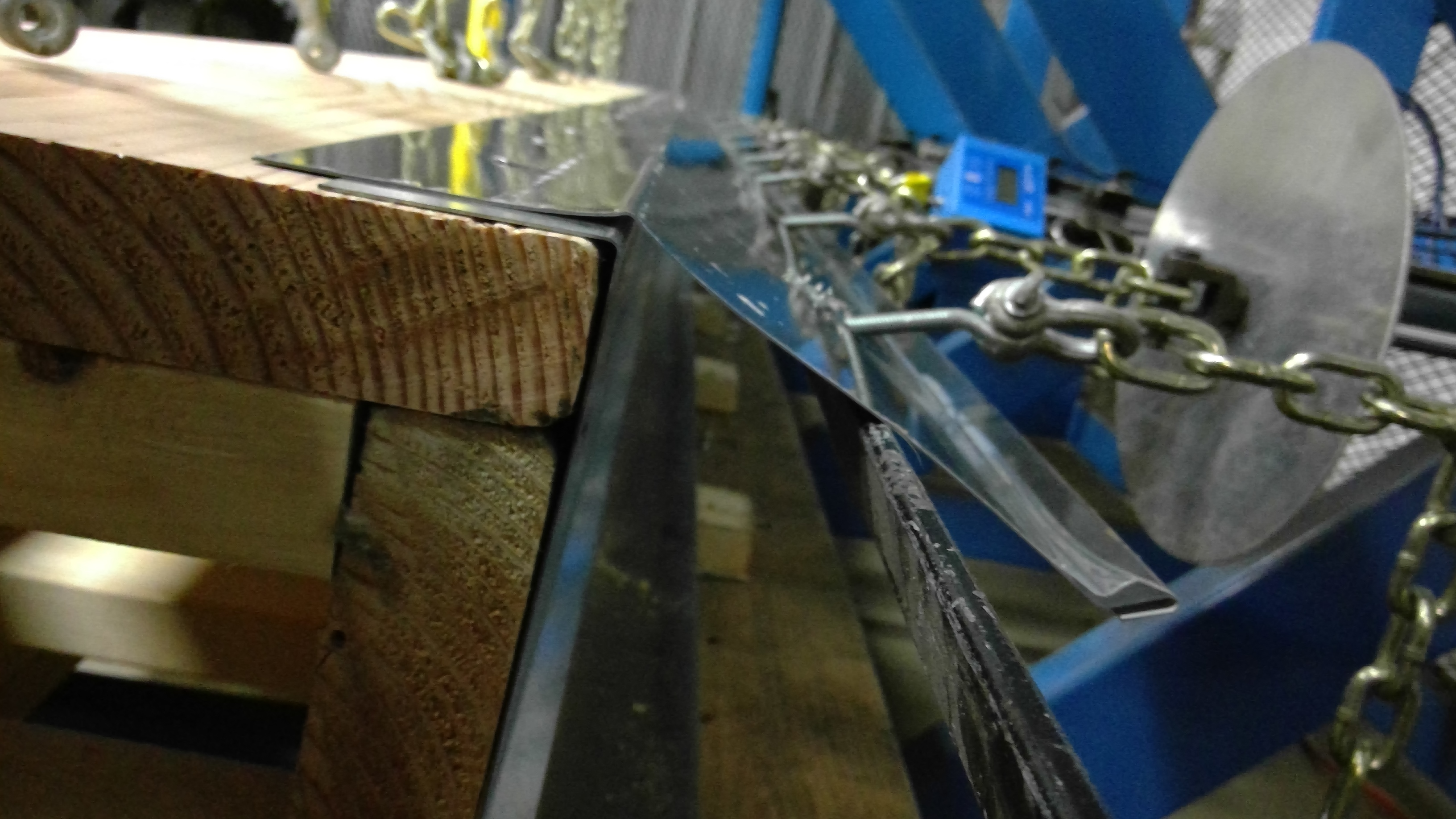

ANSI/SPRI/FM-4435/ES-1 roof edge systems are top of the line when it comes to fabrication. The systems have endured testing to prove they will hold up under extreme weather conditions. Competitors pushing untested systems will argue that they are following the same procedures, using the same material to make the same profile—it’s a solid argument to be sure—but it’s not a tested system. That said, the time, effort and money spent on developing a rated part is extensive and sometimes can take years, especially if it is novel system. Testing is a large investment, thousands of dollars per test, and there are ongoing hard costs including annual or even more frequent audits.

It should be noted that ES-1 fabricated projects need to be accounted for and tracked more closely than a standard project, increasing the cost again. Those items include:

• Tighter quality control on incoming materials, making sure they meet or exceed the specifications of the tested components

• Keeping machinery tuned and in spec with a log tracking that information

• Quality control of the final product throughout production to make sure dimensions and angles are to specifications

Every ES-1-rated perimeter system should be shipped with installation instructions to again, ensure the system is installed to the same standards that it was tested. ES-1 testing is a part of the building code in all 50 states, whether or not you choose to accept and adhere to it. It’s a growing segment of our business, so it’s of huge importance to us and our customers.

Typically, the cost of testing is offset by the flexibility that comes with being able to fabricate the ES-1 parts in-house, rather than purchasing them from someone else and paying outrageous prices for the privilege. Ultimately, you will pay more for an ES-1-rated system than a similar nontested roof edge system, for obvious reasons. More frequently than ever, architects are pushing the boundaries of perimeter systems outside the comprehensive library of previously tested offerings. This is an opportunity for the nimble and while it may not ever be fabricated for another project, unique profiles are frequently developed, tested and installed. There is no excuse not to have a system certified as necessary.

Ben Kweton, CSI-EP, is vice president of Sheet Metal Supply Ltd., Grayslake, Ill., He is also the president of Wind Testing Services Corp., an ES-1 Testing Lab in Grayslake. To learn more, visit www.sheetmetalsupplyltd.com or email ben@windtestingservices.com.