The use of solar power is becoming more common all the time. Some states, such as California, are requiring solar panels for new single-family homes and multifamily dwellings up to three stories high and will expand include new commercial buildings and certain multifamily residences starting January 1, 2023.

What contractors need to know about installing solar on metal roofs

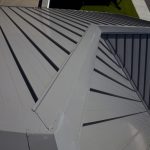

Photo courtesy of S-5!

As more roofing contractors are being asked to install solar panels, we turned to the experts for some tips on installing photovoltaic (PV) panels on metal roofs.

Types of Metal Roofs

Colorado Springs, Colo.-based S-5! CEO and founder Rob Haddock says that choosing the right platform for mounting solar panels can significantly impact both the initial and long-term costs. “With increasing popularity, the metal roof is the ideal host for mounting solar PV and enables solar PV systems to live up to their potential durability, versatility and inherent strength,” he says.

With a service life in the range of 50 to 70 years, Haddock points out that metal roofing exceeds the service life of a solar PV system, which has an average of 32.5 years. “Most alternative roofing systems will expire long before the life of the PV system leading to costly disassembly of the PV array, re-roofing and re-assembly,” he says.

Carlos Maldonado, training and technical support at IronRidge Inc., Hayward, Calif., explains that it is important to know the type of metal roof profiles in the market to get a sense of what type of mount to use for each product. While a standing seam metal roof is the most common, Maldonado notes that corrugated and trapezoidal metal roofs are starting to be used on residential applications as well. “Each metal roof profile requires a different type of attachment, therefore understanding what type of roof you are working with is important to make sure the correct attachments are used for the application,” he says.

Photo courtesy of S-5!

Inspecting the Roof

Dan Javan, CEO of Suntuity Solar, Holmdel, N.J., says before installing a solar system on any roof a structural engineer should inspect the roof to make sure that there are no irregularities and that the roof structure will be able to handle the weight of the system. “In most cases, weight should not be a problem but none-the-less a certified inspector should evaluate the structure to make sure no additional adjustments or accommodations need to be made in order to support the solar panels,” he says.

In addition to understanding the construction of the roof, Maldonado says it’s important to know the gauge of the metal roof, sine the thicker the gauge, the stronger the roof is. “Metal roofs vary from 29- to 22-gauge, which will limit the capacity of fasteners that are screwed into them, therefore knowing the gauge of the metal roof will help reaction forces of the mount capabilities. Most metal roofs are installed over purlins, which run east/west, so if the attachment needs to be installed to the structure the roof construction below the metal roof will need to determine for proper installation of the PV system.”

Photo courtesy of Suntuity Solar

Mounting Systems

While contractors direct much attention to the modules and inverters, Haddock says often too little attention is given to the mounting system that marries the expensive PV array to the host roof—the interface of array-to-roof is where the most troublesome issues arise. “It is imperative that the mounting system and all attachments to it protect and maintain the durability of the roof and do not compromise its integrity,” he adds.

Javan recommends choosing the mounting system for the specific roof type, metal roof profile and individual roof condition. Evaluating these factors, he says, will determine whether you select a railed or a rail-less system.

Javan notes rail-less systems will accommodate roofs with roof obstructions while railed systems may be more appropriate for older roofs with uneven surfaces and other irregularities. “With fewer components than a rail system, the rail-less solar mounting system improves installation efficiencies (providing 25% better load distribution to the roof) and reduces material, labor and logistics costs—a cost savings of up to 45% on hard goods alone,” adds Haddock.

Interlocking or batten-attached stone-coated steel metal roofing systems reach require different methods of attachment for photovoltaics. “Batten-attached systems tend to be more common and are easier to work with since individual panels can be removed to expose what is below them to properly install the attachment,” Maldonado explains. “Interlocking systems are more difficult to work with since individual panels cannot be removed and may require the removal of the panels for the ridge down to the lowest mount for proper installation. However, there are solutions that don’t require the removal of the interlocked panels.”

Photo courtesy of S-5!

Roof Anchors

To stay safe, Javan recommends using the proper standing seam anchor plates, which are designed specifically for use on standing seam metal roofs. Also, he recommends using a ridge pro type device to assist with installing the roof anchors.

Materials and Assemblies

It is important that the materials and assemblies used are thoroughly tested and certified, especially, Haddock says, the components that come in direct contact with the roof. “For standing seam roof installations, the recommended attachment is non-penetrating clamps mechanically attached to the panel seams with a round-point fastener that will preserve the roof’s design features and warranties, and will not compromise the metallic coating. Also, if the clamps fit the seam perfectly, the attachment system will cost less, perform better and install more easily.”

Proper Gear

Safety while working on a metal roof is always important, and since metal roofs can be slippery and difficult to walk on if steep pitched, Maldonado says using the proper safety gear is paramount for a safe and successful installation. “A pair of good work boots/shoes that provide slip resistance can help when walking on a steep metal roof,” he says. “Crouching down slightly and walking sideways up and down the roof can help with traction while working on the roof.”