Seamless, full-length, cut-to-size metal roof panel installation from eave to ridge with no chance for water or air intrusion—an ideal scenario but one rarely attained due to edges and terminations. And because of this, fastening takes on additional importance.

Correct panel attachment along terminations and edge zones can prevent a roof failure

Terminations are located near the edge of a roof where the highest wind loads sometimes occur. (Photo courtesy of Novagard)

Fastening is extremely important at metal roof panel edges and terminations for two main reasons. First, terminations are located near the edge of a roof where the highest wind loads sometimes occur. Second, any place where there is a discontinuity in a roofing surface there is an opportunity for water or air infiltration. “Wind-driven rain or snow, the capillary effect on overlaps and siphoning at the eaves can all lead to corrosion of metal surfaces,” cautions Keith Rys, regional sales manager at Novagard, Cleveland.

Jeff Haddock, technical services manager at AEP Span and ASC Building Products, Fontana, Calif., explains that roof edges experience highest wind uplift pressure, especially in corners. “If the panels are not properly secured, you risk damage to the roof panels as well as the structure or complete designment of the panel system altogether. [While] lapped panels typically take place in the middle of the roof, the middle of the roof doesn’t experience the same wind uplift pressure that roof edges and corners do, but it is no less important. Lap fasteners help secure the panel overlap connection. This also makes the laps snug to prevent moisture intrusion at the lap condition.”

Correct fastening is extremely important at metal roof panel edges and terminations. (Photo courtesy of AEP Span and ASC Building Products)

Procedures

The procedures for fastening metal panels at edges and terminations are dependent on the panel chosen for the project. Procedures can vary from manufacturer to manufacturer, and more importantly from panel type to panel type. Metal panels are rollformed in a wide variety of shapes and widths with each having specific load-resisting capacity. Each panel shape has its own unique strength and ability to resist permanent deformation.

“The panel attachment to the substrate should follow the panel manufacturers’ installation instructions as well as the design criteria specified by the metal building engineer,” says Peter Graves, PE, engineer, StruktureOne Group, Austin, Texas. “When a high-wind event occurs, roofs are subjected to different pressures and suctions as the wind is diverted around and over the building. The highest wind load areas called ‘zones’ are in the corners, and along the eaves, rakes and ridge. Pay attention to panel attachment at end laps, edges and corner zones as these panels are the only part of the building system that keeps the interior of a building weathertight. Building codes have created coefficients to calculate the additional suction and pressures in these zones.”

There are procedures to increase the capacity of the metal panels to resist these higher uplift loads at edges and terminations. Graves explains the easiest method is to simply increase the number of fasteners used along the purlin or girt line and that another procedure is to provide additional members or sub-framing members, to give more locations for panel attachment.

The Dyna-Cap metal roof terminating point flashing for trapezoidal panels has base features that allow the side wall of an end cap to form on metal roof panels. The base can also be applied at both terminating points of the sheeting or roofing material. (Photo courtesy of Dynamic Fasteners)

Fasteners

There are a variety of different fasteners used on metal roof panel edges, terminations and end-laps. Rivets, lap screws, self-drilling screws, self-tapping screws, concrete screws and anchors are all commonly used. The correct type of fastener is dependent on the application.

“Fasteners used in these areas are sometimes just a different length,” says Josh Krohn, engineering services manager, Triangle Fastener Corp., Cleveland. “Other times they might need a different head style to fit under a panel or pieces of trim. They may need a sealing washer. Some fasteners connect panels and components to themselves, and do not need to connect to structure while some are structural. Some fasteners are more visible than in the field of a roof and need to match a certain color or need to be a little more aesthetically pleasing.” The total thickness of the metal must be determined to make the proper fastener choice for a panel edge or overlap.

Exposed fastener panels come in a wide array of corrugated profiles and don’t accommodate for thermal movement because of their direct fastening requirement from end to end. Haddock says roof edge securement is a much simpler procedure that simply requires the appropriate number and type of fasteners based on the attachment medium and environment. “These panels don’t require special flashings and clips that a typical standing seam panel would require to allow for concealed attachment and thermal movement requirements.”

Sealant plays a crucial role as a back-up defense against moisture intrusion especially at edges and terminations. (Photo courtesy of AEP Span)

Also, for exposed fastener roofs, an electric screw gun or battery drill with a depth setting nosepiece or clutch is recommended. “A clean magnetic socket will help prevent scratching paint off the head of a fastener,” says Andrew Mullen, president of Direct Metals Inc., Fort Myers, Fla. “The installer does not want to overdrive the fastener or crush the EPDM washer, which could strip out the fastener and lead to an eventual leak due to fastener backout.” Ken Webb, sales manager at Dynamic Fastener, Kansas City, Mo., agrees the correct use of a screw gun is important to avoid errors, especially when installing self-drilling screws. “Versa-Clutch adjustment systems will allow the contractor to dial the proper torque needed to efficiently drive fasteners without stripping or breaking the fastener.”

Sealants

Sealant plays a crucial role as a back-up defense against moisture intrusion. Sealants and metal roof panels work together to protect the underlayment, especially so at edges and terminations. Proper sealing of end laps will avoid water being driven up-slope or where lapped joints may experience periods of standing water or become submerged. Since metal panels expand and contract with changes in temperature, sealants (they consist of polymers that allow flexibility) aid metal panel joints that experience dynamic movement.

Butyl tape can seal end laps and overlaps against moisture penetration. (Photo courtesy of Triangle Fastener Corp.)

To prevent metal roof leaks, Mullen advises using high-quality butyl mastic or tube sealant, to seal end laps and overlaps against moisture penetration. “Proper placement of butyl mastic between the overlap ribs is important to prevent a siphoning effect of rainwater trying to penetrate between the panels.”

Check that the sealant is in the correct position and is in complete contact with the lapped panels without any voids or gaps, especially at any radius between the panel flat and the vertical legs of the panel. Rys advises using a bead large enough to bridge the joint and provide good coverage and adhesion to both surfaces. “We often see failures where the sealant is applied with the tip favoring one side of the joint.”

Bobby Raymond, owner of Louisville Metalcraft, Louisville, Ky., believes surface preparation is the most important factor for a successful job. Also, “Proper tooling technique is critical. Apply caulk in one direction, tool the opposite way. Don’t caulk in the hook strip at the bottom edge of a standing seam roof. If you caulk in the hook strip, the system won’t drain and water will end up siphoning at the eaves.”

Krohn cautions one of the more common errors that can occur when fastening metal roof panel edges, terminations and end-lapping is, “relying too heavily on sealants to keep water out. To avoid this, make sure you are using the correct fasteners and following the specifications as prescribed for all the components. Also, apply sealant as directed. Use the proper sealant, the correct amount of sealant and apply it in the right areas. Do not rush. Keep everything clean and neat. Do not use an excessive amount of sealant as the first line of defense for watertightness.”

Lap fasteners help secure the panel overlap connection and also make the laps snug to prevent moisture intrusion at the lap condition. (Photo courtesy of Novagard)

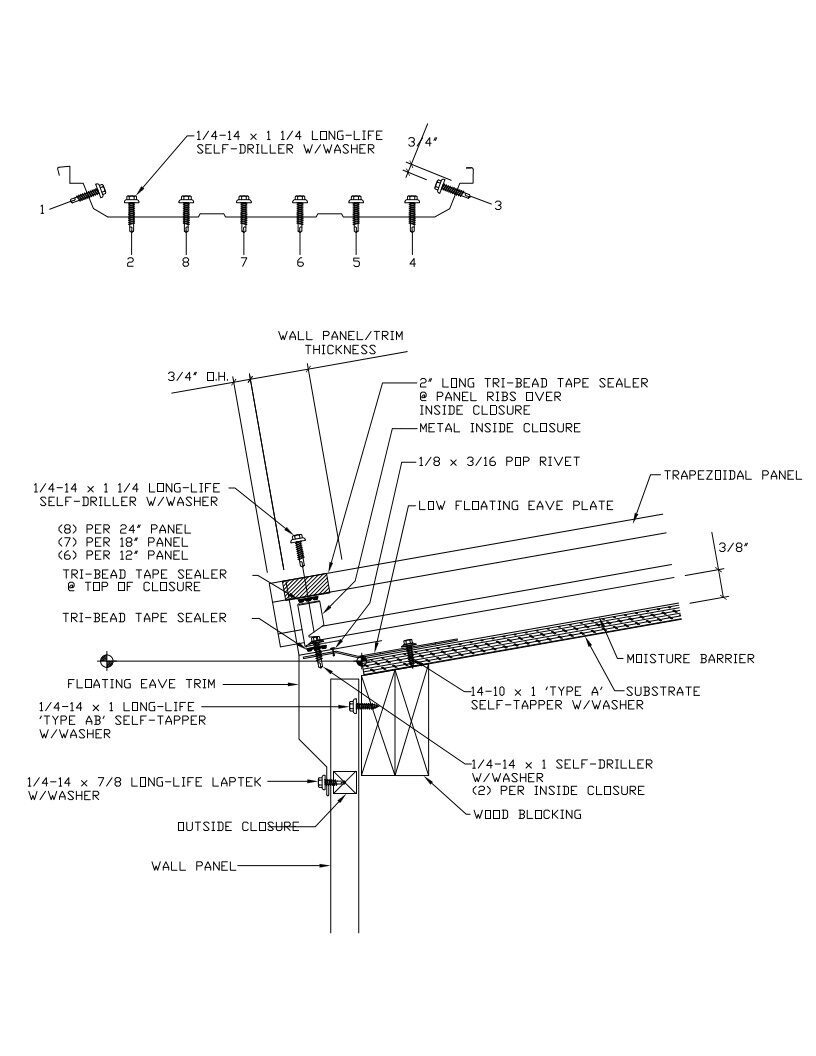

This technical drawing shows a metal trapezoidal panel fastened and sealed to a wall. Drawing courtesy of StruktureOne Group