A day does not pass that does not provide an interaction into the capabilities offered by roof curbs. Project scopes and construction materials continue to evolve to provide occupant enhancements that meet the requirements of specific building purposes.

Correctly integrating rooftop equipment with a roof curb system

Low-rise commercial structures embodying retail, manufacturing, institutional and nearly all other applications contain valuable assets that typically require temperature control, daylighting, ventilation and/or maintenance with the roof providing the most efficient solution to accomplish these. The only way to correctly integrate that rooftop equipment is by a roof curb system.

From the under/over or shingle style installation with the roof, to the metal type selection to avoid dissimilar material reactions, the surface-level details are only a small portion of what makes a successful solution.

As the liaison between the building and equipment, a suitable curb system must embody weathertightness and structural integrity in its most basic function while also facilitating the proper use of the mounted apparatus. There is no universal design, especially in buildings clad by metal roofs, as the pitch, panel type and equipment differ on nearly every project. Therefore, a total systems approach is necessary to achieve pre-engineered metal building dynamics such as thermal movement, panel offset, full-perimeter support and air leakage in roof penetrations, which subsequently require specialty closures, compatible installation accessories and sub-framing in addition to the curb itself.

Sealing a curb to the roof to eliminate potential leaks is accomplished in similar fashion to typical roof panel splice and eave details incorporating backer plates, rolled mastic, long-life fasteners, rib plugs and, most importantly, placement specifications that yield resilient performance.

Where things tend to go wrong is the curb support as field-executed frames that are often used do not accommodate the elevation offset provided by differing roof clips and component-style backers are inadvertently pinned to the purlins or joists, preventing thermal movement.

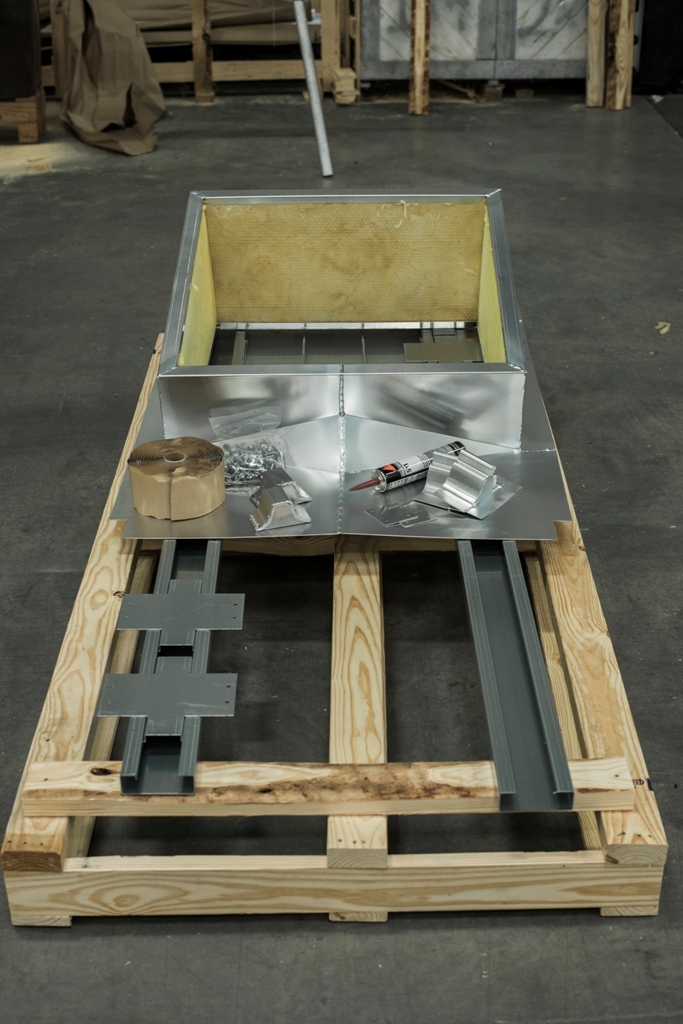

Floating roof curb sub-framing designed to handle specific loads is the ideal solution for penetrations on metal roof systems. Not only does it accomplish the support necessary to transfer the equipment load to the building, but a correctly designed curb sub-framing also acts as a perimeter backer to provide proper compression with mastic sealing the curb flanges to the roof panel when coupled with properly tightened and placed fasteners. A factory notched sub-framing package in addition to the thoughtfully sourced accessories alleviate installation stress and compatibility concerns, furthermore solidifying the systematic approach necessary for metal roof curbs.

Curb usage is not limited to a mere metal sloped box with cricket and framing kit; ventilation, accessibility and daylighting are a few of the single-source assemblies well within the capacity of reputable systems providers. Manufacturing equipment and paint booths often require large stacks or ducts to ventilate through the roof based on their location in a building. Those penetrations not only require curbs, but specialty flashing such as square-to-round covers and storm collars for watertight results.

Equipment maintenance in water treatment or chemical plants often entail routine access through large roof openings to vessels and tanks where it is impractical to simply remove roof panels. Removable access covers designed to complement building loads mounted to roof curbs are the only efficient solution for this access. These are just a few examples to get the most out of a roof curb system offering comprehensive solutions that accomplish the building’s purpose.

Whether it is on the roof or through the roof, there is a curb system for it, but I challenge you to consider the ancillary details that matter most. Does the curb you are buying have closures, sealants, backers and fasteners that are compatible with the roof panel assembly? Does your curb have framing that accommodates the roof panel offset, thermal movement and transfers the equipment load to the structure? In a world of constant uncertainty, use a specially designed roof curb and be certain that you are sealed and supported with the confidence of a system on your side. For any rooftop application, weathertightness and structural integrity are the best curb appeal on any project.

Clifton Reasor is vice president of business development at Roof Curb Systems, Trenton, Ga. For more information, visit www.roofcurb.com or email creasor@roofcurb.com.