A roof underlayment is a membrane installed directly on the roof deck, under metal roof panels, and provides a barrier from the elements including rain, snow and wind. A well-designed and installed underlayment prevents moisture from seeping through the roof deck into the building interior.

The critical role of an underlayment in a metal roofing system

The Costs and Causes of Moisture Infiltration

Over time, a wet roof deck will rot or deteriorate, and moisture will inevitably affect the living or working space of the interior of the building. The results can be inconvenient at the least but can also lead to property damage and mold growth.

Moisture infiltration through a roof system can occur directly from precipitation penetrating the roof covering through a deteriorated roof system or improperly installed panels. The leaks may be exacerbated by wind-driven rain, particularly in areas prone to high winds due to the wind pushing the rain through susceptible parts of the roof covering.

In northern climates, leaks can also occur due to ice damming. This refers to ice that accumulates in certain areas of the roof and holds back melting snow stacked above it. The ice dam can stay for long periods of time in the same area, allowing snow melt trapped above it to penetrate through any susceptible areas in the roof covering.

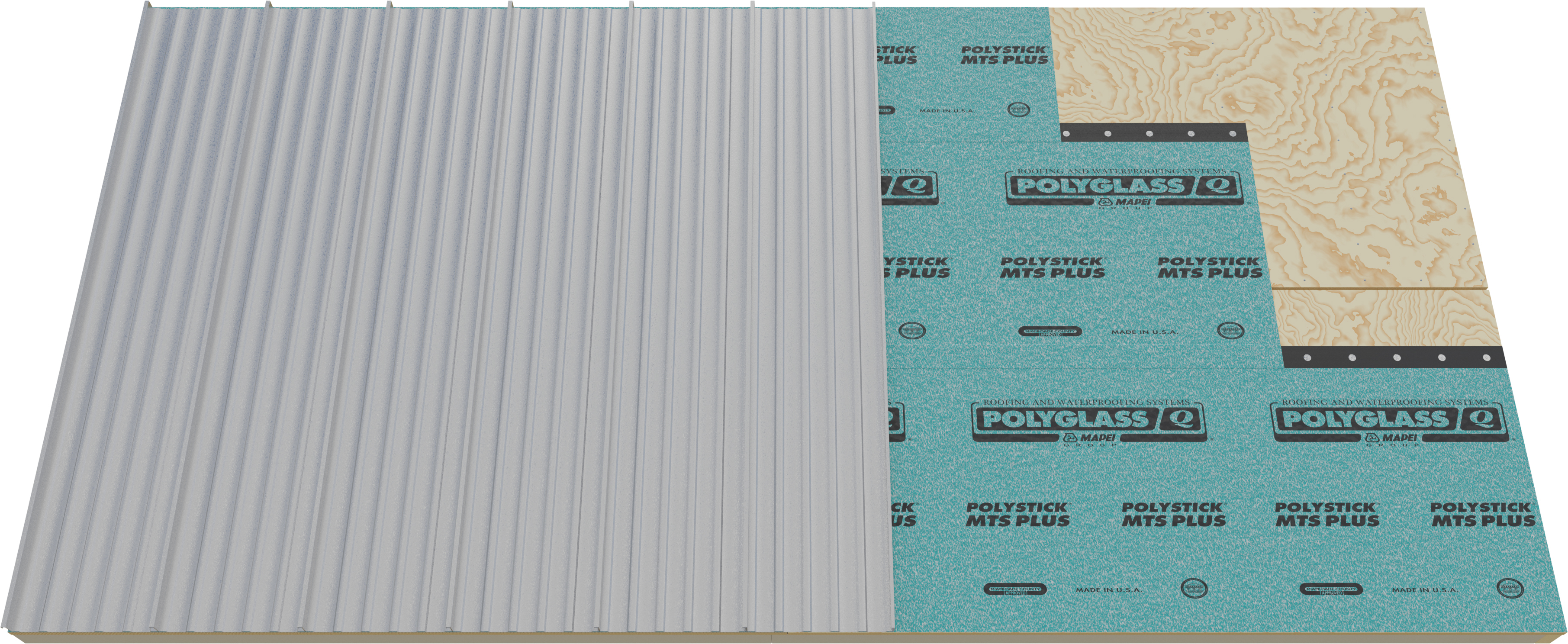

Underlayments for Metal Roofing

A typical metal roofing system is often characterized as having a high temperature environment; the potential heat captured below the metal cladding can be much higher than other roofing assemblies. An underlayment system considered for metal roofing should be approved to perform in these situations and ensure continuous and long-term waterproofing protection.

Additionally, the UV exposure rating should also be considered. Polymer-modified underlayments can typically sustain exposure for 90 to 180 days, depending on the quality of the compound and the top surface.

Types of Metal Underlayments

The most common types of underlayments currently on the market are explained below.

• Asphalt-saturated organic felts. One of the most traditional types of underlayments are asphaltsaturated felt paper. Organic felts became popular because they were cost effective and provided a moderate level of coverage from moisture infiltration to the deck below. They are generally not available for use in high temp (HT) applications, a requirement typical under metal roofing.

• Modified bitumen self-adhered underlayments. Self-adhered membranes comprised of polymermodified asphalt have been around for decades, however, advancements in technology continue to make these a popular choice today, particularly in regions where there is wind-driven rain and/ or ice damming. The polymers added to the asphaltic compound increase the durability of the underlayment against UV, heat and thermal shock. The bottom surface’s adhesive qualities increase the installation speed and removes the need for nails or fasteners. A synthetic film top surface is typically recommended for metal roofing because the smoother surface does not affect the metal finish and standing seam panels are able to slide freely back and forth during thermal cycles.

• Synthetic underlayments. Synthetics are the newest form of underlayments. They are plastic sheets typically composed of polypropylene, polypropylene/polyethylene blends, and other polyolefin resins. The manufacturing processes can vary to produce thicker or thinner membranes, different degrees of UV resistance, as well as a variety of coated textures to enhance walkability.

Marco Sieber is national product manager at Polyglass, U.S.A. Inc., Deerfield Beach, Fla. To learn more, visit polyglass.us.

Maxx Leverage Roofing & Restoration, Miami installed underlayment at The Hyatt House Hotel, Miami, for better moisture protection.