|

Fasteners are an essential piece of any metal building project. From the framing to the metal wall and roof panels, fasteners are necessary to put any metal building together. With fasteners being such an important aspect of any project, it is also important to make sure that you are using the correct type of fastener for each piece of the building, since when improper screws are used, both the fastener and the panel system can fail.

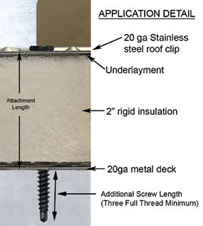

When selecting fasteners for metal wall panels, Joe Stager, vice president of product development and marketing at Cleveland, Ohio-based Triangle Fastener Corp., says that the most important thing is to do is use a fastener that is specified by the panel manufacturer. “If none is specified, select a screw that is designed for attaching into the thickness of the girt and long enough to allow at least three full threads to extend beyond the girt.”

|

Keith Self, product manager at Birmingham Fastener Inc., Birmingham, Ala., adds that since a fastener is only a small part of a larger system, it is only going to be as strong as the material it is fastening. “Many factors determine which fastener is best suited to your specific application. Although several different fasteners may work for the application, some will perform better in each circumstance. Material substrates, gauges of materials, even where a particular building is being erected can determine proper fastener selection.”

Critical Factors

Structurally, there are four critical factors that should be considered when selecting a fastener, explains Tom Hulsey, director, technical services and applications engineering at SEALTITE Building Fasteners, Tyler, Texas. They are:

- The thickness, or gauge, of the steel girts through which the fastener will be installed. “This will narrow the options of available fastener diameters and point configurations,” he says. “The fastener must be capable of successfully drilling through the structural girt without failure.”

- The spacing of the girts and the spacing of the fasteners along the girt will determine the surface area of the panel that is dependent upon the fastener’s ability to resist the negative forces that would tend to pull the fastener out of the structure (often referred to as pull-out) or to pull the wall panel over the head of the installed fastener (pull-over).

- The design wind loading is an important factor to determine the actual forces that could be exerted on the wall panels. “That force will define the minimum strength requirement of the fastener in terms of pull-out and pull-over resistance,” he notes.

- Knowing the metal panel gauge and the configuration of the wall panel will help to accurately determine the diameter of the fastener head or the diameter of the sealing washer that will be responsible for resisting the pull-over forces on the wall panel.

In addition to the above factors, there are a number of aspects of fasteners that contractors should keep in mind when selecting the right ones for installing metal wall panels.

Fastener Material

What material a fastener is made up of is an important consideration. Hulsey notes that while material selection is based upon the function and the expected long-term performance of the fastener, Self adds that factors involving dissimilar metals and galvanic reaction must be considered, including how the fastener will react with its environment, as well as the materials it is being used to attach.

“Generally speaking, the industry uses carbon steel fasteners due to their cost effectiveness and performance ability,” says Eric Velliquette, vice president of sales and marketing, Atlas Fasteners, Ashland, Ohio. “Carbon steel is a harder material that enables the ability to manufacture fasteners with a drill point.”

“Most self-tapping screws used to attach metal wall panels are made of c1018-c1022 carbon steel,” says Stager. “These screws are case-hardened so that the surface of the screw is hard enough to tap the steel sheet and girt without stripping. There are also special ‘ductile’ tapping screws that are produced from alloy steel like c4037 that will bend without fracturing. They are designed for applications where excessive expansion/contraction or vibration is a concern and may cause a standard case-harden screw to fracture.”

Velliquette notes that 300 series stainless steel comes in a variety of grades and has great corrosion resistant properties, making it the material of choice when looking for a fastener with high ductility properties. Additionally, he adds that 410ss are used for customers who like the corrosion properties of the 300ss, but like the ability to have a fastener with a drill point.

Head Shape

For metal wall fasteners, there are two main head shapes-pancake and hex head. Hex head (external drive) screws provide the best installation stability compared to pancake head (recess drive) screws, according to Stager. Hex head fasteners are used for exposed fastener applications and concealed fastener panels when clearance is not an issue, he notes. Stager adds that pancake head screws are primarily used in concealed fastener panels where there is limited space in the joint of the panel, in addition to exposed applications when a low profile screw head is more aesthetically pleasing. While pancake head fasteners have a recessed configuration in the head for installation, Hulsey notes that hex head fasteners have a recess under the flange of the head to capture a sealing washer. “The hex shape allows for a more positive configuration to drive the fastener without damaging the surface finish,” he says.

|

“For light trim applications, a pancake head fastener works well,” notes Velliquette. “When you need a fastener for thicker applications, hex head fasteners work great due to higher drive torque requirements.”

Self adds that pancake head fasteners are limited to certain lengths and diameters, while hex heads are limited on sizes and drill abilities.

Fastener Length

|

Fasteners are measured from underneath the head to the tip of the fastener, and the necessary length required is determined by the total thickness of the components being assembled. “The length of the fastener is best described as being the sum of the unthreaded drill point length, the length of the threaded body, and any unthreaded shank directly under the bearing surface of the head,” explains Hulsey. “The thread length should provide for full diameter threads to be engaged in the girt and at least two full threads to project through the girt when the fastener head (or sealing washer) is correctly seated against the wall panel and the assembly is correctly tightened.”

Stager notes that by having at least three full threads that extend beyond the material that is being tapped by the threads will allow the threads to tap the girt enough to produce acceptable pull-out and clamping loads.

Fastener Styles and Points

|

| Self-drilling screws |

Fasteners come in to styles: self-drilling or self-tapping. Stager notes that the main advantage of self-drilling screws is the ability to drill and tap the material in one operation, eliminating the need to pre-drill the materials, while self-tapping screws provide a fast and inexpensive alternative to drill-screws and typically produce higher strip-out loads when attaching to thin steel 20-gauge or less. Hulsey adds that self-tapping fasteners are manufactured without the drill point feature and require pre-drilling the girt with the proper sized drill bit for the diameter of the fastener being used.

“Erectors of wall and roof panels on steel-framed buildings generally use self-drilling fasteners,” says Hulsey. “Self-drilling points are sized to provide the correct hole diameter and point length for a specific range of girt thickness for a specific fastener diameter and thread type. When the thickness of the structural girt becomes significantly greater, a larger point diameter is needed in order for the following threads to properly engage the structural member without breaking the fastener.”

Velliquette explains that self-drillers have five different sizes ranging from #1 through #5 point, while self-tappers have three point types that include Type A, AB and B. “Whether it is a self-driller or self-tapper, each point has its own characteristics which make it superior for its proper application.”

|

| Self-tapping screws |

“Gimlet point and drill-point screws are capable of piercing and tapping steel,” explains Stager. “Gimlet point (sharp pointed) screws can pierce up to 20-gauge steel. Drill-point screws can drill and tap up to 1/2-inch-thick steel. Some points like Type BP are designed to assist the installer in positioning the screw into a ‘blind hole’ so that the thread taps successfully.”

Washers

Washers play an important role in a building’s weather tightness, preventing leaks and adding in back-out resistance. Velliquette notes that it is important to choose a fastener with a non-conductive rubber washer. “The washer of a fastener becomes a barrier between two dissimilar metals,” he says. “When moisture is present, along with conductive washers, electrolysis begins to take place creating enhanced corrosion.”

“Washers are primarily composed of either EPDM rubber or neoprene rubber,” Self says, “with EPDM having a higher melting point and is more UV stable.” Other considerations are the difference between a “bonded washer” (metal-backed washer), and the “flange washer” design. The flange is part of the fastener’s head and has a loose EPDM washer, he adds.

|

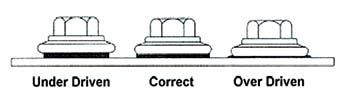

Stager recommends choosing a bonded sealing washer that uses non-conducted EPDM sealant that has been vulcanized, and not glued, to the metal backing. “This will provide the optimal seal and minimize galvanic corrosion between the washer and the panel.” He continues, saying that for undercut head screws, make sure the washer is made of non-conductive EPDM material as well. “Be aware that the diameter of the washer provides a bearing surface against the panel that effects the pull-over strength of the panel over the screw and washer assembly. For optimal sealing capabilities, tighten the screw until the EPDM extrudes to the edge of the screw’s washer face.”

Coatings

The purpose of coatings is to protect the fastener from the corrosive effects of the environment, while improving the aesthetics of the installed assembly, explains Hulsey. “Coatings on fasteners provide not only protection against corrosion but can also provide lubricity to allow the thread to tap the girt with acceptable torque,” Stager adds. “When corrosion of the fastener occurs, it can cause the fastener to fail due to stress corrosion cracking or other forms for corrosion induced fastener failure. It is recommended that any exposed fasteners be plated and coated with superior finishes that minimize corrosion.”

“Depending on environment and application, coatings are vital to the overall success of the attachment,” says Self. “Any fastener exposed to the elements needs to meet the requirements of the panel manufacturer, normally the tests consist of a salt spray test (ASTM B117) and a Kesternich test (DIN 50018), both tests compare the resistance to corrosion.”

Hulsey notes that carbon steel fasteners must be coated to protect them from red rusting. While the most common means of protection is zinc plating, painting or applying powder coating can provide additional protection. For stainless steel fasteners, Hulsey notes they are generally coated for color matching the panel, since corrosion resistance is generally not an issue.

Choosing the Right Fastener

When choosing fasteners for metal wall panels, Hulsey notes that contractors should be looking for a fastener that will provide the structural strength necessary to satisfy the building specifications and meet all applicable code requirements. “Performance properties that are important to the contractor are drill performance, sealing characteristics, long-term corrosion resistance and ease of installation.”

“Contractors should primarily be looking at what the application consists of, and what job the fastener will perform to determine the best way to achieve the desired results,” Self says. “Some factors to consider are pull-out, pull-over, tension strength and shear strength. Proper safety factors should always be used in all applications.”

“A fastener that has both superior corrosion resistance and consistent drill performance will save the contractor money, creating increased profitability,” adds Velliquette.