Today’s pre-engineered metal building systems are a versatile solution that can be built almost anywhere in the United States and internationally. However, there are certain things that require close attention when designing and building in different regions.

“Many of the design variables in metal building construction are similar to those found in conventional construction: varying soil conditions, climate factors, wind and snow loads all impact design decisions with metal buildings,” says Marcelo Reyna, LEED AP, project manager at Phoenix-based Arrington Watkins Architects. “Most of the regional differences in metal building result from detailing to respond to these various environmental factors.”

Each region should be looked at based on utilizing the proper loads and codes that will impact a metal building systems, says Burt Shell, director of national accounts at Nucor Building Systems, Waterloo, Ind. “Loads and codes for certain areas can be influenced by snow, ice, temperature changes, wind, coastal zones and seismic forces.”

|

| Perched atop the beautiful Donner Summit, Woodward Tahoe Training Facility at Boreal, Soda Springs, Calif., is a 33,000-square-foot action sport and cheer training facility. It contains indoor ski jumps, foam pits, trampolines, skate and BMX park, gymnastics and dryland training areas. Sitting at an elevation of 7,200 feet, the facility is designed to meet local snow load codes. J & S Construction, Truckee, Calif., was the builder. |

Snow Loads

Snow loads are of concern mainly in northern and colder climates. Influenced by elevation, general weather and moisture patterns, slope direction, exposure, roof configuration, wind direction and severity, snow load factors can dramatically impact a building’s design. “Heavier gauge metal girts and roof purlins are typically specified to help with the additional loads,” says D. Thomas Goderre, PE, LEED AP BD+C, vice president, district manager at Gilbane Building Co., Phoenix. “Typically, additional steel is also used in the frames and bracing to address the required snow loads.”

Special design considerations need to be taken into account not only for the additional potential snow loads on the roof system, but also potential maintenance of that snow load during building operations during heavy snowfall, depending on the roof slope, explains Goderre.

In areas with high snow impacts, Shell notes that it’s also important to look at products to be incorporated in the final design of any building project. “The structure itself has a function and a performance, but one needs to look at and understand the building system and its components.

Today’s design-build solutions take into account many applications, such as cranes, conveyors, rooftop assemblies-i.e., HVAC, skylights, solar products-and canopies in areas where heavy snow and icing occur,” he says. For example, canopies. Contractors, architects and owners may not look at incorporating a flat canopy design in these conditions, and may instead utilize sloped systems that help move elements of nature off the structure that could impede the performance standards of the building’s design.

In colder climates, ice protection and snow cleats are required at roof edges, especially over building openings and pedestrian walkways, notes Goderre. Additionally, building eave edges are sometimes solidified with bent plates instead of sheet metal.

“When you get into areas with heavy snow and icing, you want to look at long-term maintenance and serviceability,” Shell notes. Components installed after a building contractor and steel erector have done their part can create additional loading and building stress if not properly taken into account. “Focus on the fundamentals of how materials impact the structure, how they may impact the loading, roof maintenance, performance and serviceability. Every building owner is looking to purchase a building system and solution that offers safety, quality and long-term performance for the investment.”

|

|

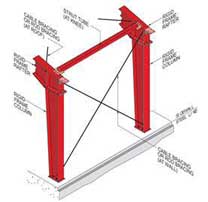

This image highlights a typical pre-engineered building sidewall bay condition where “X” bracing is attached to the columns and rafters to resist forces, along a strut tube that is bolted within the roof secondary framing. |

Seismic Forces

Many areas of the country are susceptible to potential earthquakes and seismic forces, making it important that a pre-engineered building stand up to those forces. “Foundations for metal buildings in regions with high seismic requirements need to be designed to handle the large reactions at metal building frames,” says Goderre.

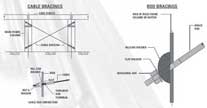

Longitudinal bracing helps resist forces due to wind, earthquake, cranes and other stability issues, says Shell. Cable or rod “X” bracing is the most common brace types used. Additional design and pricing options include: pipe struts-used in roof and wall planes at locations where the axial capacity of a purlin, girt or purlin strut are exceeded; angles-used in place of cable or rods; and portal frames-a rigid frame designed perpendicular to the primary frames where a brace condition can’t accommodate full-height “X” braces.

Shell goes on to note that in some high seismic zone areas, and particularly the western U.S., they are seeing increased use of buckling restrained devices. Shell describes this as a rubber band encased in concrete that allows the building to move without snapping the band.

|

|

The heavy blue shaded areas, noted along the western

and eastern coastal zones, indicates conditions where high winds can and do develop. The lighter interior blue shading are regions impacted by down-slope winds, severe thunderstorm conditions and most common, straight-line winds. |

Wind Loads

In addition to snow loads and seismic forces, wind loads need to be taken into account when designing and building pre-engineered systems in different regions. In general, metal buildings perform fairly well in extreme wind loading locations, since the skeletal frames and repetitive girts provide multiple points for resisting of lateral supports, explains Goderre. Additionally, in areas with higher uplift requirements, metal buildings require additional connections and bracing to resist the extra forces.

ASCE 7, “Minimum Design Loads for Buildings and Other Structures,” defines three exposure categories for winds. Exposure B, defined as the roughest terrain includes urban, suburban and wooded areas. Exposure C includes flat, open terrain with scattered obstructions and areas adjacent to oceans that are in hurricane-prone regions. Exposure D is considered the smoothest terrain, and includes areas adjacent to large water surfaces outside of hurricane-prone regions, mud flats, salt flats and unbroken ice.

Shell notes that there are other wind conditions that a pre-engineered building manufactured system can encounter, including down-slope winds, hurricanes, northeasters, thunderstorms and straight-line winds. While straight-line winds are the most common to occur throughout the U.S., down-slope winds are typical of the western and parts of eastern U.S., and thunderstorms are most common in the Southeast and Midwest. And, as their name states, northeasters (nor’easters) occur along the U.S.’s northeastern coast.

“We take these wind conditions into account as we look at a building because high wind speeds tend to impact the envelope performance,” Shell explains. “We’ve got to make certain we have the proper design, whether it’s for tornados, hurricanes, or heavy induced wind speeds in specific areas of the country.”

|

| The 95,000-square-foot Schluter Systems Distribution Center and Training Facility in Reno, Nev., consists of a 75,000-square-foot warehouse constructed with pre-engineered steel and a 20,000-square-foot office constructed with structural steel. Miles Construction, Carson City, Nev., was the builder. |

Soil Conditions

In the different regions, bearing capacity of the soil is extremely important when foundation systems are designed for a pre-engineered building. Typically, a metal building’s foundation consists of footings, piers and grade beams along with a slab on grade. “The footings and the wall piers are always centered under the columns, and that is the support that not only helps the pre-engineered building perform, it also helps hold the building in place,” Shell says.

Methods of resisting horizontal forces used in today’s pre-engineered building foundations include tie rods, hairpins and moment-resisting foundations. “Other methods growing in use, which can strengthen shallow foundations with applications, may include chemical grouting, jet grouting, micropiles and helical piers,” notes Shell.

“It’s important to establish the soil bearing capacity of the location the building will be constructed,” he continues. “Across North America, there are challenges facing those who design foundations, whether on rock, poor, corrosive or expansive soils and foundations in areas with a deep frost line. It is important that contractors do their homework when qualifying their foundation designer. Find one who has a quality reputation, recognizes how to determine the soil types and especially understands the relevant geotechnical issues to make the building system perform properly.”

|

| This image shows two standard longitudinal “X” bracing applications pre-engineered building manufacturers can incorporate into their structure to resist forces due to wind, earthquake, crane systems and other stability issues. |

Regional Design and LEED

With LEED 2009, the USGBC introduced Regional Priority Credits, which encourage specific regional environmental priorities to be addressed when it comes to the design, construction and operations of buildings in different geographic locations. The Regional Priority Credits address six specific environmental issues within a region, which were identified from among existing LEED credits with the help of USGBC’s regional councils, chapters and affiliates.

Specifications

While metal buildings are very adaptable to most climates and environments, Reyna notes that there are cost ramifications for building in different regions. “For example, additional roof loading requirements in regions with heavy snowfall, heavier foundations and structure for seismic areas, additional connections and bracing for areas with heavy wind loading and uplift conditions.”

“Any and all loads and codes for today’s pre-engineered building solutions must be qualified and confirmed with local building officials where a project is to be built,” Shell explains. “That responsibility also rests on the shoulders of the building contractor purchasing a pre-engineered building system. For every project, the entire design team must look at the loads and codes, they must be confirmed and that information must be clear and in writing to the pre-engineered building manufacturer designing the building.”

“Aside from weatherization issues, costs, aesthetics and function typically become the most important factors in design decision-making,” Reyna adds. “The historic low-cost of metal buildings compared to traditional building types have been the primary factor in their success.”

NOTE: All photos courtesy of Nucor Building Systems