The demand for AI, cloud infrastructure, and cold-storage is fueling rapid growth in data center and cold-storage facility construction. These projects prioritize speed, scale, and uninterrupted operations, driven by aggressive build schedules and heightened performance expectations. Yet despite the high stakes, roofing systems are sometimes an afterthought in the design and specification process. If the roof fails, the consequences are immediate and costly, leading to downtime, interior damage, thermal instability, and compromised product or data reliability.

In mission-critical environments, precision and reliability are paramount. The roof is more than just a structural covering; it must function as a resilient shield capable of withstanding extreme environmental conditions. Getting it right from the start is essential to safeguarding consistent uptime, controlling energy use, and ensuring the long-term performance of the building envelope.

Why roofing matters in high-stakes builds

Data centers are engineered with built-in redundancy to ensure uninterrupted uptime, where 70 percent of facility outage incidents cost $100,000 or more, according to Uptime Institute’s Annual Outages Analysis 2023. These facilities house sensitive digital infrastructure that requires tightly controlled environments and maximum operational continuity. Similarly, cold-storage facilities demand challenging temperature and humidity regulation to protect perishable inventory, comply with food and pharmaceutical safety standards, and maintain consistent product quality.

In both cases, the roofing system plays a crucial but often underappreciated role. It must be designed to prevent thermal loss, vapor drive, condensation, and moisture intrusion, any of which can compromise performance, safety, or profitability. Whether the priority is protecting critical data servers and cooling systems or preventing heat transfer in cold storage, the roof should be treated as a mission-critical system. With so much at stake, choosing the right roof is critical and depends on a facility’s operational priorities, environmental risks, and long-term performance expectations.

The role of metal in mission-critical roofing systems

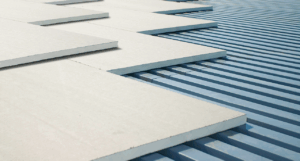

Metal roofing systems offer long service life, structural strength, and fire resistance, which is particularly important in fire-prone and climate-sensitive environments. In data centers and cold-storage facilities, standing seam systems and insulated metal panels (IMPs) provide tailored design flexibility and robust structural performance, with IMPs also enhancing thermal efficiency.

Assemblies incorporating edge metal, insulation, and roofing membranes are ideal. These are engineered to meet seismic requirements and high wind uplift ratings, especially when combined with edge metal for perimeter securement. Using metal means faster installation and seamless system integration, which are essential for high-speed builds such as massive data campuses or refrigerated warehouses.

Metal edge is an essential yet often overlooked component of these systems. As the first line of defense against wind uplift and perimeter failure, particularly in buildings with single-ply membranes, edge metal is vital to the long-term integrity of the roof system. Edge metal must be properly engineered and installed to meet stringent building codes, including ANSI/SPRI ES-1 and FM Global standards. Whether specified as part of a pre-manufactured fascia or a custom-fabricated coping system, secure perimeter metal helps prevent membrane detachment. In mission-critical facilities, even minor breaches can lead to significant consequences.

The shift toward PVC and high-performance membranes

Polyvinyl chloride (PVC) membranes are increasingly specified in fire-prone regions and cold environments due to their fire and chemical resistance and dimensional stability. These attributes make PVC a reliable choice for facilities that demand durability and performance. PVC is also available in a range of colors to meet both energy performance and design needs. For example, white membranes support reflectivity goals in warmer climates, while darker options like charcoal are often chosen in colder regions. In cold-storage applications, PVC is especially well-suited for vapor control and helps maintain insulation performance over time, particularly when installed as a fully adhered system, which helps limit membrane movement and air intrusion. Its ability to resist degradation and maintain a consistent barrier helps ensure the building envelope performs reliably.

Beyond durability, PVC membranes offer exceptional thermal regulation, waterproofing, and vapor barrier capabilities. In roof assemblies, the membrane acts as a primary vapor barrier, helping prevent warm, humid exterior air from entering the roof system and condensing as it moves toward colder interior spaces. This function becomes even more effective when paired with properly engineered edge metal and strong perimeter systems.

Designing for redundancy and code compliance

Like generators and backup systems, roofing assemblies should be built with layers of defense to mitigate environmental and operational risks. This means incorporating vapor barriers, staggered insulation, and sealed air layers in cold-storage facilities to prevent condensation and preserve thermal performance over time. For both cold-storage and data center applications, meeting or exceeding FM Global, UL, and local building codes is not merely a matter of compliance; it is a strategic approach to ensuring long-term resilience. Engaging manufacturers early in the design process helps ensure that roofing systems are built to spec, fully code-compliant, and tested to perform under each facility’s specific conditions.

Post-installation support and long-term performance

Roofing resilience is a long-term investment that depends on certified installation, strong warranty protection, and ongoing technical support. In cold-storage environments, maintaining thermal continuity and airtightness is essential; any failure in the roofing system can lead to increased energy costs and heightened risk to temperature-sensitive inventory. To safeguard performance over time, contractors and building owners should reach out to technical teams to schedule inspections and assist with any repairs. Whether adapting to rooftop solar installations, refrigeration system upgrades, or severe weather events, comprehensive post-installation support ensures the roof continues to perform as designed throughout its lifecycle.

Sustainability and thermal efficiency

Data center and cold-storage owners emphasize reducing energy use intensity (EUI), driven by ESG commitments and evolving regulatory standards. High-performance PVC membranes and high-R-value insulation are crucial in minimizing HVAC and refrigeration loads by improving thermal efficiency. In cold storage specifically, this insulation has demonstrated much better thermal performance than conventional polyiso insulation in cold climates, delivering measurable energy savings and operational cost reductions. Additionally, the recyclability of metal roofing components and membrane materials helps facility owners and managers practice circularity.

Roofs are a strategic infrastructure

There is zero margin for failure in data center and cold-storage construction; roofs must perform like any other mission-critical system. Resilient, code-compliant, and high-performing roof assemblies protect service reliability, operational continuity, and return on investment. Owners, developers, and specifiers should engage roofing experts early in the project to avoid reactive solutions later. Partnering with the manufacturer during the design phase helps ensure these standards are met. The takeaway is simple: a roof is not just a cap on the building; it is the foundation of reliability from the top down.

Robert Pate is a strategic account manager for Amrize, focused on data center solutions for Elevate Commercial Roofing Systems. Pate, who has a Bachelor of Science in mechanical engineering from the University of Alabama, has been with what is now Amrize since 2017.