To help balance and complement a glass curtain wall system, insulated aluminum infill panels—sometimes referred to as glazing panels or glazing inserts—are often incorporated into the system. Insulated glazing panels can provide increased energy efficiency to the building while providing an improved aesthetic. The panels are most often square or rectangular in shape and designed to span the area between floors or walls, as well as used in storefront entrances and door systems.

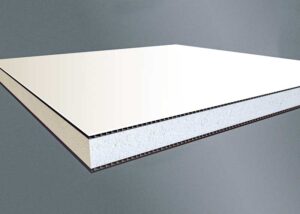

Insulated infill panels feature an insulating core bonded to stabilizers and aluminum skins. The most common insulating cores are polyisocyanurate (ISO), expanded polystyrene (EPS), extruded polystyrene (XPS), mineral fiberboard, or calcium silicate. Each insulating core option provides different properties, and some are better than others for their energy efficiency, fire-resistance, moisture resistance, strength, sound absorption, and overall cost.

It is important to select a product that meets the specific requirements of the project. Stabilizers help to protect and strengthen the insulating core, and are often made of plastic, hardboard, or plywood. Infill panels made with plastic stabilizers are more lightweight and moisture-resistant than those made with hardboard or plywood. The aluminum skins used on glazing panels typically range in thickness from 0.33 to 0.812 mm (0.013 to 0.032 in.) depending on the manufacturer and color selected and are available in a smooth and/or stucco-embossed finish depending on the product. In many cases, custom colors are an option to match the desired color palette of the project or to accommodate corporate identity program requirements.

After insulated glazing panels started to gain popularity in different glazing systems, panels that provided different aesthetic or energy-saving options became desirable. This trend caused manufacturers to produce a wider variety of insulated glazing panel options. Examples include rabbeted edge panels, wrapped edge panels, and stepped edge panels. Rabbeted edge panels are designed to provide increased insulation on the panel’s interior face, where it is typically not visible. These types of panels are typically available in a 7- or 8-ply panel that can more than double the R-value depending on the overall thickness of the panel. Wrapped edge panels provide an edge treatment that allows for metal-to-metal, butt-glazed joints and create a clean, hairline joint appearance. They are used in applications where the opening in the curtainwall system exceeds the maximum panel size that is available, allowing panels to be installed next to each other. Stepped edge panels provide appealing aesthetics to the building by providing an adjustable reveal between the face of the mullion and the face of the panel. They can also provide a flush exterior aesthetic if desired.

With the evolving code requirements and focus on fire safety, a recent trend has been to incorporate more non-combustible products into buildings. Non-combustible infill panels are relatively new to the market and typically include a calcium silicate insulating core and thin plastic stabilizers. This type of panel meets the non-combustible requirements of the International Building Code (IBC), section 703.5.2.

Aluminum insulated glazing infill panels are typically lightweight, durable, and low maintenance. In many cases, the panels provide R-value performance and insulating properties comparable to insulated glass units and can provide unique aesthetics, especially when multiple or custom colors are incorporated.

Shawn Crouthamel, CSI, CDT, is the architectural national sales manager at Laminators Inc., Hatfield, Pa. For more information, visit laminatorsinc.com.