From the basic slasher system technology of yesterday to the advanced, fully automated coil warehouses of today, new technologies have revolutionized metalforming. With the rising popularity of metal in construction projects, including walls and roofs, contractors are leveraging various levels of automation to manufacture materials in-house and improve their operations.

Layers of automation include:

Manual systems: Manual systems require operators to handle all aspects of coil processing, from positioning slitting knives to measuring and cutting materials. While cost-effective for small-scale operations, these systems are labor-intensive and prone to human error.

Semi-automated systems: Semi-automated systems balance affordability and efficiency. These systems automate repetitive tasks, such as knife positioning and job tracking, while allowing workers to oversee operations with minimal training. They are ideal for mid-sized contractors to scale their operations without significantly increasing overhead costs.

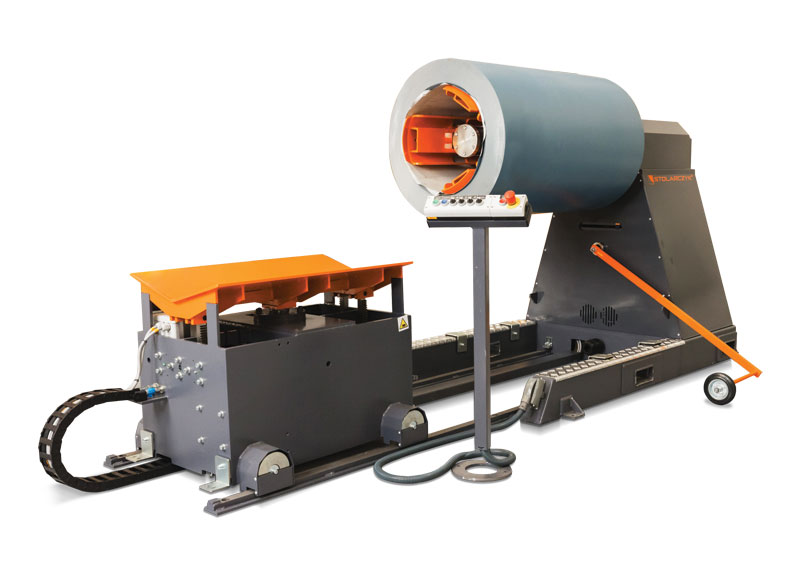

Fully-automated systems: Fully automated systems handle everything from coil storage to cutting and slitting, reducing manual intervention to a supervisory role. Features such as enterprise resource planning (ERP) integration allow seamless job transitions, often taking less than two minutes. Though costlier, fully-automated systems deliver efficiency and scalability, enabling contractors to meet varying customer demands rapidly.

The evolution of coil processing

How did we get here?

The origins of coil processing in the architectural sheet metal market date back to the late 1990s. Initially, only large manufacturers with significant financial resources could afford the equipment. These systems allowed these companies to capitalize on bulk purchasing and

in-house processing, but the high cost put them out of reach for smaller contractors and regional manufacturers.

Making coil processing accessible

In 1998, the industry saw a breakthrough with the introduction of more affordable coil processing solutions. This dynamic began to shift with the first slit-to-width and cut-to-length machine, which met customer demands at a price point appropriate for a broader audience. Priced at approximately $50,000, this equipment opened doors for mid-level manufacturers and regional businesses. Contractors gained the ability to control inventory, produce on demand, and customize materials.

The rise of automation

The mid-2000s ushered in the era of semi-automated systems. These systems automated previously manual tasks, such as positioning slitting knives and tracking job specifications. Software integration further enhanced efficiency by optimizing material usage and streamlining processes.

Contractors could download job specifications directly into control systems, reducing errors and labor-intensive adjustments.

Between 2012 and 2015, fully automated coil warehouse systems revolutionized the industry. These systems automated slitting knife adjustments and managed coil storage and retrieval. Additionally, coils could be loaded into a warehouse, remaining untouched until processed. Automated systems selected and staged coils based on job requirements, significantly reducing non-value-added movement and potential damage. Additional features, such as film application and barcode labeling, streamlined downstream processes and improved traceability.

Challenges and benefits of in-house coil processing

The transition to in-house coil processing brings challenges, including:

- Space requirements: Companies must reevaluate their raw materials storage requirements and allocate space for the new equipment.

- Skillset advancements: Advanced systems require training and operational adjustments.

Initial investment: While now more affordable, advanced systems still represent a substantial investment.

If companies make these changes to their processes, the benefits are significant:

- Cost savings: Contractors can reduce material costs by processing coils in-house rather than purchasing

pre-cut sheets. - Operational flexibility: On-demand production reduces dependency on external suppliers and enhances scheduling efficiency.

- Improved jobsite control: Materials can be produced to the exact specifications needed in a timely fashion. This flexibility reduces delays and ensures mistakes are corrected quickly, preventing

project disruptions. - Increased revenue opportunities: Contractors can diversify their services by supplying processed materials to other businesses.

Inventory control: A single master coil can serve multiple purposes, simplifying inventory management. Smaller coils can reduce storage challenges and align with existing equipment capabilities, such as forklift capacities.

Why coil processing performance matters

Effective coil processing starts with quality materials and a reliable supplier with a solid reputation. Purchasing in bulk allows contractors to negotiate costs down to fractions of a penny, which can make a significant difference at scale. A good supplier relationship may include inventory management support, such as holding stock for contractors to save shop space.

Contractors must consider their current processes and decide whether to mimic existing practices or implement new ones. For example, transitioning from purchasing flat sheets to processing coils in-house requires robust straightening systems to ensure flatness. Protective films may also be necessary to prevent damage during storage and handling, with different options suited for various materials.

In-house coil processing eliminates unnecessary steps, such as transporting materials between multiple stations. Systems with adjustable slitting knives and efficient stacking solutions can streamline operations, reduce material handling, and enable just-in-time production.

Automation and sustainability

Technology in coil processing continues to evolve, with hybrid systems bridging the gap to reduce costs and make automation more accessible. Customizing materials on demand offers unparalleled control over job timelines and reduces reliance on external suppliers. Automation ensures contractors can adapt to economic fluctuations while meeting sustainability goals through optimized material usage and reduced waste.

Advanced systems also support sustainability initiatives by minimizing overproduction and excess handling. Contractors increasingly recognize the importance of having the right materials—precisely when needed—to ensure project success.

Coil processing and automation have transformed the metal construction industry, offering cost savings, operational efficiency, and business growth opportunities. By bringing processes

in-house, contractors gain control over their projects, reducing delays and improving job site adaptability.

Chad Rowe is the director – business development for MetalForming. Rowe spent the first nine years of his professional career with the US Navy as a nuclear submarine-trained electrician. Joining MetalForming in 1999 as a field service technician, Chad has 25 years in the industry serving in multiple capacities. He is currently providing customers with the guidance necessary to find the optimum solutions to their architectural sheet metal needs.