Job costing is the process of tracking all the costs related to a job or project to determine profitability, control expenses and price confidently.

Job costing helps make better decisions and keeps projects profitable

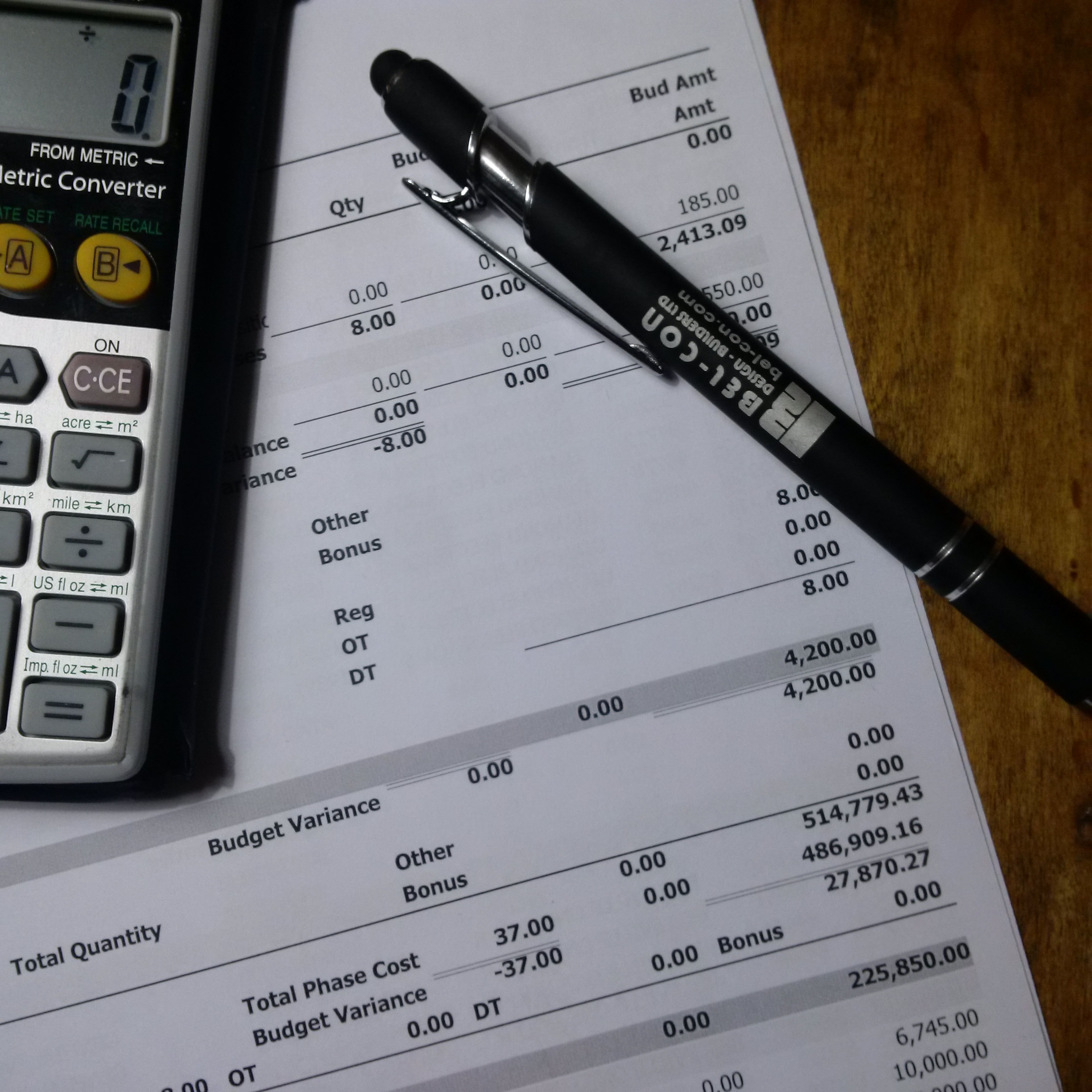

Job costing tracks all the costs related to a job or project to determine profitability, control expenses and price confidently. (Photo courtesy of Bel-Con Design-Builders Ltd.)

Effectively and accurately estimating job costs can indirectly result in project success or failure. Job costing eliminates guesswork and generates accurate estimates on time. When this process is done right, management can monitor whether projects are on track and on budget before it’s too late.

With a willing management team and a general knowledge of software and technology, contractors can establish a job-cost budget for each project based on figures provided by the estimator. “The estimate is entered at the start of the project and costs are applied as the project progresses,” says Tom Gunsinger president,Bel-Con Design-Builders Ltd., Belleville, Ontario, Canada. “The project costing is available to all staff involved with the project including remotely on the site by field personnel who enter labor daily by cost code.”

Essential to any business’ bottom line, job costing is especially crucial in the construction industry. Often the most complex aspect of construction accounting, it can accurately predict, record and monitor material, labor, subcontractor and equipment job expenses. In some industries, predicting job costs is fairly straightforward, but not necessarily in construction. Construction projects can have a volatile profit margin due to the number of unforeseen factors.

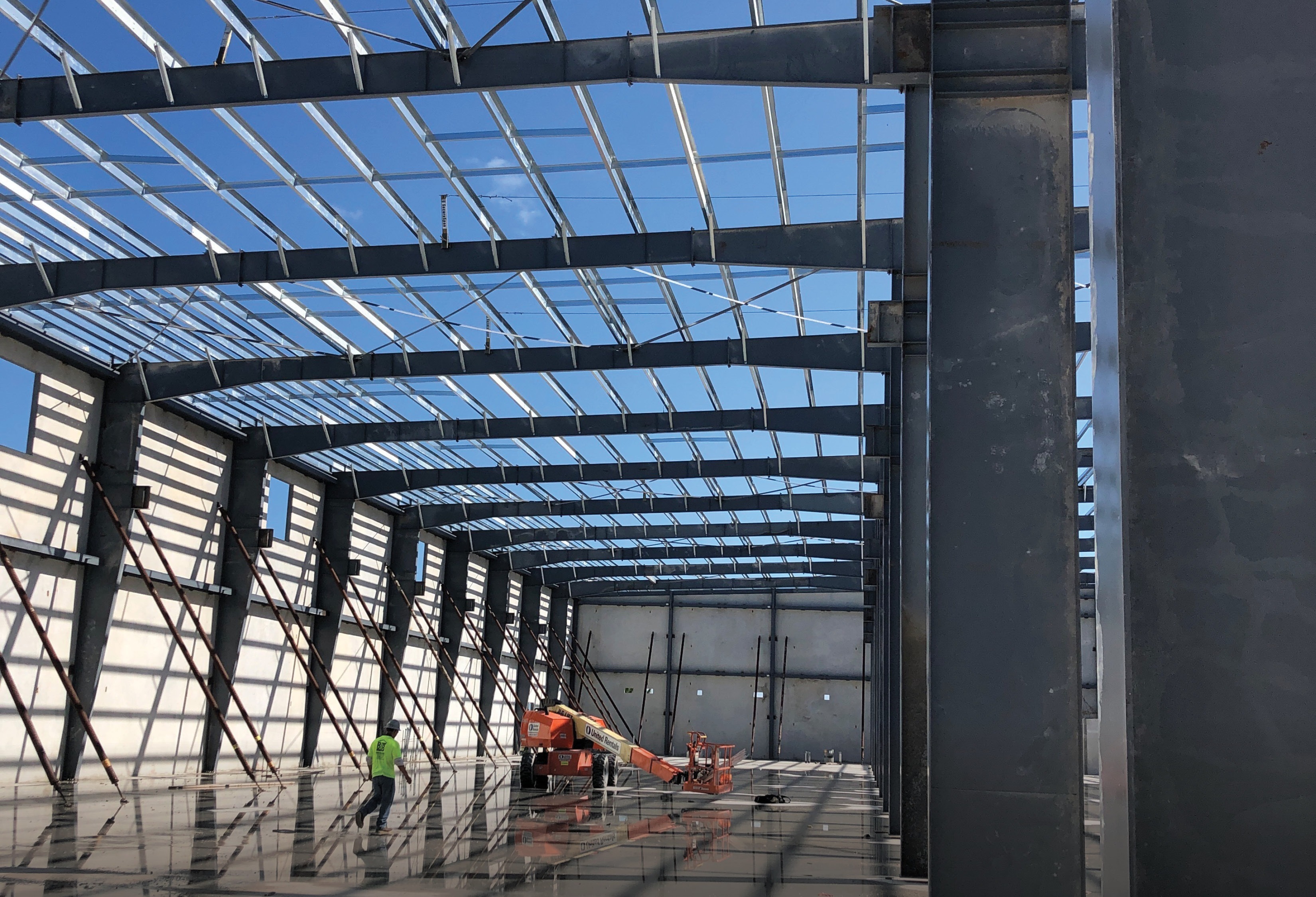

A complex aspect of construction accounting, job costing can accurately predict, record and monitor material, labor, subcontractor and equipment job expenses. (Photo courtesy of Thomas Phoenix International Inc.)

These can include labor overruns, unpredictable material costs, and external factors such as weather or changing regulations. A project may seem routine, but once started, there could be unforeseen complications. Additionally, errors may need correction. This increases the amount of time and materials required to complete the job, and increases labor and materials costs. You may even need to employ a subcontractor or rent additional equipment. Gunsinger admits that although there are a lot of similarities from one building to the next, there are also enough differences that virtually no two projects are the same; further hampering construction job costing.

Misfabrications or a lack of planning can cause huge cost overruns, but this can be minimized with correct job costing. “When a deficiency or misfab needs to be corrected during primary framing erection, it becomes an immediate roadblock,” says Joseph Allen, project manager, safety and training manager at Thomas Phoenix International Inc. (TPI), Eastampton, N.J. “No one wants to cover the cost of a crane and rental equipment sitting idle, or the erection crew standing around waiting for an engineer’s solution. In metal construction, there are quite a few fly-by-night operators who run out and slap a logo on their pickup truck and hire a few unskilled laborers and call themselves erectors. Unfortunately, with the low-bid nature of so many contracts today, some of these contractors start bidding large projects and then quickly get in over their heads. Then they have to cut corners or abandon safety protocol to try and compensate for poor costing.”

Via accurate job costing, many of these variables can be better handled by breaking down the entire project into smaller pieces to track expenses to specific areas of the project. Contractors can view expenses at both the micro and macro level. Construction business owners can determine which projects, tasks or crews are making or losing money. With this level of information, a business owner or contractor can make adjustments to ensure the profitability of a project and develop a profit plan to drive future projects and drive major business decisions. Referring back to previously job-costed projects can anticipate the time needed to complete a similar project with confidence.

The Process

As an erector, Allen says costing manpower and equipment is “everything.” He says this information is key to adapting each bid so that it’s as accurate and detailed as possible.

“Site visits, drone footage and photo/video progress updates from a GC help to project equipment needs and make sure everyone’s on the same page,” Allen adds. “Can we set a crane in the footprint, or will we need to get a bigger stick and set our steel from the perimeter? Will we need scaffolding or articulated lifts due to limited access? Try to get as much information as possible in the bidding stage to understand the how of what will be expected, and there will be fewer surprises at ‘go-time.’ There will always be surprises. We consistently track past and current performance, and correlate it with all available situational data to help arrive at the most viable and realistic costing estimate. In plain words, this means figuring out the things that have caused overages in the past and learning how to avoid or overcome them in the planning stage.”

Construction management solutions simplify the process of collecting real-time job cost data, and then organizing the data, and finally visualizing the information to derive business insights. (Image courtesy of Lemartec Corp.)

Travis Lefever, managing member at Buildings By Design, Brush, Colo., excels at job costing by using a very robust spreadsheet. “Every item that is in our scope is broken down by line item within the spreadsheet and is assigned a job cost code. This allows us to track costs real time, as they come into the project managers. Not only does job costing help us monitor our budget, it helps us with our post-mortem reports, and allows our estimators and pre-con manager to see where actual costs were versus their estimates.”

Labor Intensive

Construction labor is frequently a project’s primary cost, but it is often the most difficult variable to job cost. Because of this, TPI asks the question, “Provided the proper equipment and supervision, and mindful of the anticipated job-site conditions, how long will it take in man-hours to complete a project?” Allen says this is based on historical performance, project complexity, building manufacturer, type of cladding, type of insulation system and the requirements to perform the tasks within TPI’s safety parameters and quality control. “Often we see that low bidders neglect temporary bracing, fall protection and general safety requirements,” he says. “We’re quite often hired to remedy the problems that unprepared or unscrupulous erectors have caused.”

Miami-based Lemartec Corp., a MasTec company, prepares a comprehensive job cost budget using a standardized work breakdown structure (WBS) to allow for an in-depth view of the project budget at a line item level. This allocates and reserves the use of that budget into specific line items. “In terms of labor, this level of detail can provide you visibility into crew and management team efficiency helping the project management team make decisions, which can contribute to bringing the project in under budget,” says Joseph Socarras, CGC, project controls manager at Lemartec.

“At the very beginning of the project when budgets are being calculated and assigned, a staffing plan should be made to take account of all man hours expected to be consumed,” Socarras adds. “You may have crews which mobilize day one and exit month three, while other crews may overlap with each other at certain points in their shift, etc. This level of detailed planning is critical in forecasting the labor dollars expected to be consumed. Once the project hits the field, this labor is tracked by completing and confirming daily timesheets and tracking against the expected man hours for that reporting period. This level of tracking will also give the project management team insight into labor productivity against the physical percentage of completion achieved in the field.”

Overpaying and Job Costing

Job costing is not a perfect science and when one construction variable cost turns out wrong, how do you make up and adjust for that money elsewhere? Buildings By Design uses a coded line item system to avoid overpayments. “Our costing spread sheet is taken directly from estimation and pre-con, and converted into our accounting system, using the same line items and cost codes,” Lefever says. “If we have overpaid for an item, it is because the project wasn’t estimated correctly. As costs come into our PM they code them per the cost codes that correspond within our accounting system.

However, in the event a scope item has been misestimated, our job costing system allows us to see real time if we need to move costs between on line item to the next. Generally, we leave lines items as a loss if they were estimated incorrectly, so our estimators can learn from their mistakes and take those costs in account, next time they estimate a project.”

Through value engineering and effective job costing, the best solution for this project was the use of a combination of a pre-engineered metal building and concrete tilt-up wall panels. (Photo courtesy of Lemartec Corp.)

Depending on the type of project (tendered versus design-build) and the type of issue encountered, Bel-Con would assess if the issue warrants a change order, which would eb the case if the issue is beyond its control. “We also share all of our estimates with our superintendents and steel crew foremen at the start of the project so that all are aware of the expectations and if something is running over budget they will be able to spot that item early on,” Lefever says. “If the issue is solely on us; e.g., we under estimated an item, then having timely and accurate job costs allow for these events to be identified early on and we can look for ways to minimize or eliminate the cost overrun.”

For the past year or two, Casey Grover, business development and estimating manager at Carros Metal Concepts, Villa Rica, Ga., has seen the fluctuation of metal pricing become a new factor in job costing. “Most manufacturers give you a 30- to 60-day price guarantee. After that, it’s subject to change. In our industry, most projects aren’t ready to have materials ordered in this time frame. Combining this with the fluctuating prices of metal, it’s been trial and error the past couple of years. Sometimes, you’re able to make up for these factors, other times you’re not. To combat these unforeseen elements of the industry, we incorporate waste/error factors within our estimate spreadsheet.

Is this 100% foolproof? Certainly not, but it does provide a small contingency fund for overlooked items. Typically, with a good and trusting relationship with your manufacturers, they’ll work with you and help out when they can. That’s an advantageous part of building trusting relationships not only with your manufacturers, but your subcontractors, contractors, clients, etc.”

Comparing Cost Numbers

When your numbers for job costing are different than those in other departments what is the next step? Allen says the discussion of job costing (especially for unusual projects) should inherently involve project management from the outset.

“A discrepancy typically only arises when the estimator neglects or cannot foresee an issue that might be plainly visible to personnel more involved in the field. If it’s discovered that costing is drastically different between departments, a conversation about means and methods is appropriate. At no point in the process should worker safety be compromised to compensate for an estimating deficiency. If there is a good working relationship between the controlling contractor or GC, it’s occasionally possible to describe the issue and partially offset costs by tighter scheduling of equipment or process.”

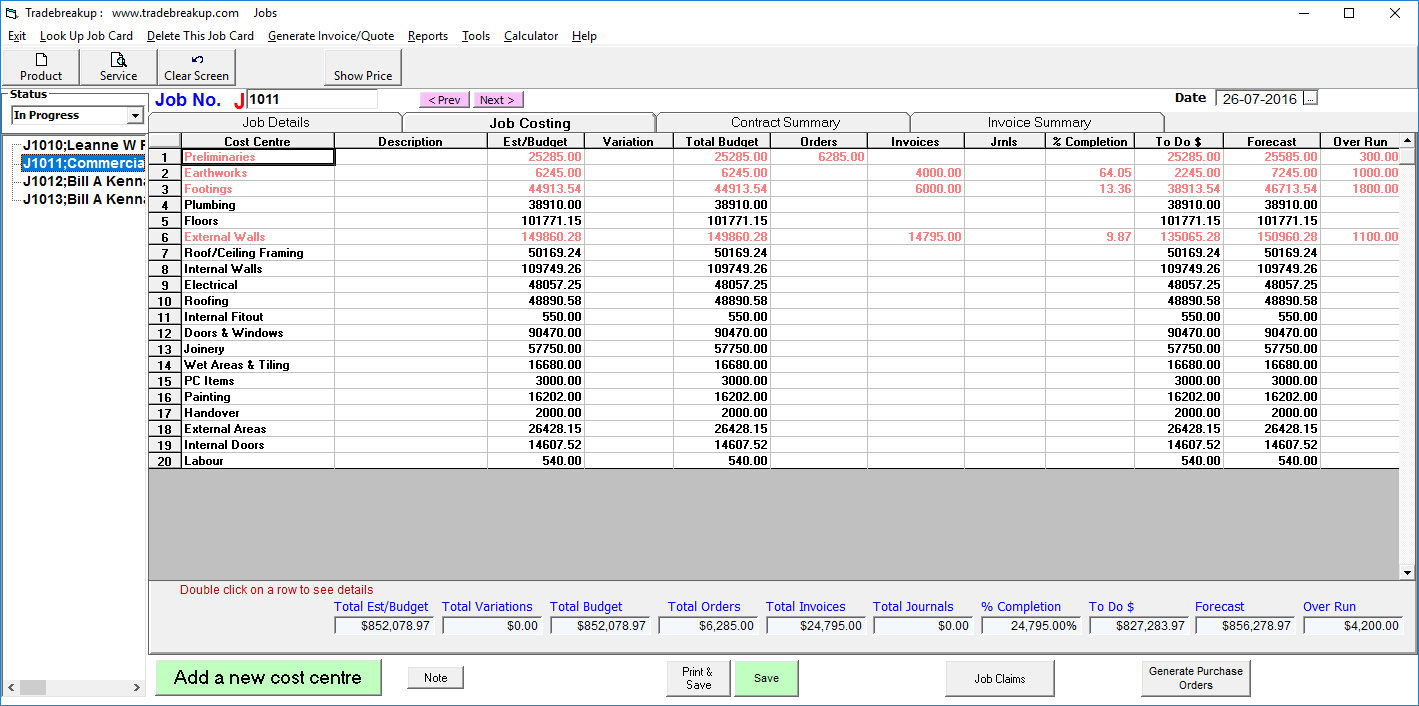

This job costing screen’s job costing tab keeps track of job costs within all trade types and cost centers. (Image courtesy of Tradebreakup)

At Bel-Con, project managers review job costs as the project progresses in terms of labor spent versus estimated. “We utilize a purchase order system for all purchases of materials and equipment—including rental of lifts, cranes, etc.—as well as for subcontractors,” Gunsinger says. “As these purchases are made they are compared to the estimate and discrepancies may require seeking additional pricing or making other alterations to maintain budget. As invoices are submitted and entered our accounts payable department compares each invoice to the purchase order for compliance. Any discrepancies are brought to the attention of project personnel before processing.”

At Carros Metal, Grover says these numbers are some of the most important—seeing whether it achieved its goal, which would be meeting its budget or performing better, or missing it entirely. “In this industry, with this data, you can truly learn from your mistakes. Whether it was material in section, not shown in elevation that was missed, calculation error, error in your formula, underestimating the time needed to complete the work, or a multitude of other factors, you can look back and see how the job should have been approached to be more profitable. On the other end of the spectrum, you could perform 5 to 10% better, which is great for that project, but if you’ve bid in this fashion for say two months, how many projects have you missed out on for being too high? All of this information plays a key roll into ensuring your success in an ever-changing market.”

Technology Can Help

Construction management solutions simplify the process of collecting real-time job cost data, and then organizing the data, and finally visualizing the information on built-in reporting dashboards to derive business insights. “Instead of using multiple spreadsheets or disparate file-sharing tools, contractors can use a single tool to capture and track financial documentation, such as invoices, purchase orders, change orders and bills of material,” says Pritam Tamang, analyst at Software Advice, Austin, Texas. “This ensures that contractors are constantly tracking project budgets based on real-time data. For instance, just as a change order is captured and approved in the system, a corresponding change in the project budget is automatically reflected. With the consolidation of a project’s cost data in a single system, contractors can understand the status of the project budget more effectively and identify cost overrun areas faster, allowing them to make timely cost adjustments to stay profitable.”

Software assists Lemartec’s job costing by providing controls to job cost postings and preventing overpayment to vendors. By requiring unique invoice numbers, fixed subcontractor and purchase orders, these controls can help prevent errors and confusion. “The software can help track and organize cost commitments and expenses against cost codes,” Socarras says. “However, a good understanding of the system, budget and scope is necessary to prevent errors and provide accurate forecasts. As with any system, the quality of the data input will result in the quality of your reporting. The advantage to having real time reliable data is that we, as contractors, can make educated decisions with more speed.”

Whether it’s a management process to share spreadsheets or an integrated commercial construction management platform, Allen contends putting the right information into the right hands makes the difference between success and failure.

“While the bells and whistles of subscription project management software are attractive, quite often they are either jam-packed with features that are never used by smaller companies, or they lack the customization options that allow them to be tailored to fit exactly into an efficient workflow. I think that smaller companies too often overlook the importance of capturing and sharing data, which can be achieved quite simply through the effective use of basic Microsoft Office software.”

Lefever advises finding a system that works for you and your line of business. “Take different ideas from different companies or programs and let them evolve into a system that you know and understand. Spend time job costing—there can be key indicators to help find where a company or project is bleeding money from.”

Job costing tries to take into effect unforeseen conditions like work stoppages and bad weather. (Photo courtesy of Bel-Con Design-Builders Ltd.)