London’s 2017 Grenfell Tower fire, Dubai’s 2016 Address Hotel fire, Melbourne, Australia’s 2014 Lacrosse apartment building and the California wildfires were all high-profile events that put the spotlight on fire safety and building fireproofing.

Here’s what’s new in building fire safety codes and fireproofing

(Photo courtesy of Maxim Tajer on Unsplash)

Because of this, building owners, life safety experts, designers/ architects, manufacturers and associations have been evaluating and examining their current protocol, procedures and products to protect the public. While no building is fully fireproof, what follows are updates and information on recent developments to prevent fire-related building tragedies.

New, Amended and Proposed Fire Codes

Auto-exposure and leapfrog describe the upward spread of fire from one floor of a building to the floor above. Fire on a lower floor can break through the vision glass of windows and reenter through a window above. This condition allows the fire to ignite combustible cladding materials, breaking out more windows and perpetuating the fire’s climb up the building. This was the case in the Grenfell Tower fire where flames climbed 20 stories in just 35 minutes.

“[Many] have carefully examined the factors that may have accelerated the Grenfell fire’s vertical spread,” says Angela (Angie) Ogino, technical services leader, Thermafiber/Owens Corning, Wabash, Ind. “As post-fire analysis points to possible concerns with the building code, new testing standards are being proposed to address the threat of vertical fire spread on a building’s exterior. A new testing method has been proposed that addresses the threat posed by vertical fire spread. ASTM E2874-19 assesses risk of fire spread vertically from floor to floor. A gap in current codes to address leapfrog risk is a huge concern, particularly in buildings where occupants may be unable to evacuate on their own. To support architects in assessing leapfrog risk, the new testing method ‘ASTM E2874-19: Standard Test Method for Determining the Fire-Test Response Characteristics of a Building Spandrel-Panel Assembly Due to External Spread of Fire’ has been developed by ASTM Subcommittee E05.11.”

Mineral wool insulation for cladding provides protection around perimeter joints. (Photo courtesy of Thermafiber/Owens Corning)

An unrelated code change involves UL Standards related to fire testing of solar panels on metal roofs. “‘UL 2703, Standard for Mounting Systems, Mounting Devices, Clamping/Retention Devices, and Ground Lugs for Use with Flat-Plate Photovoltaic Modules and Panels,’ now includes exemptions for fire tests of certain panels with noncombustible mounting systems installed on Class A roof assembles with steel metal panels,” says Vincent E. Sagan, PE, senior staff engineer, Metal Building Manufacturers Association (MBMA), Cleveland. “These revised standards have been adopted in the 2021 International Building Code.”

Johnston, R.I.-based Factory Mutual (FM) Global recently released “FM 4411 Approval Standard for Cavity Walls and Rainscreens,” which is inclusive of the air space cavity in the range between 1 to 4 inches and is applicable for FM-insured projects. This fire-performance test uses a full-scale cavity wall assembly and evaluates the fire propagation behavior of combustible insulation in a configuration that is representative of the actual installation. “FM standards should be used for FM-insured buildings only,” says Mandi Karns, director of engineering design and development at CENTRIA, Moon Township, Pa. “These standards can be used as guidance for non-insured buildings but should be discussed with the design team.”

A new ASTM E3037 Standard is titled “Standard Test Method for Measuring Relative Movement Capabilities of Through-Penetration Firestop Systems.” It is reportedly the only standard that covers movement in penetrations.

“This [ASTM E3037] standard defines movement as a cyclic movement of the firestop system in two distinct planes (Y direction and Z direction), which are parallel and perpendicular to the annular space,” explains Ed Goldhammer, director, codes and approvals, firestop at Plano, Texas’ Hilti North America. “The intent of the standard test is to show movement capabilities for firestop system when situations occur beyond the normal rigid support of the penetrations. Seismic, high winds, blasts, vibrations, floor deflection and mechanical systems are just a few of the reasons for movement in buildings. The use of the standard is not limited; it is intended for use in buildings where firestop systems are exposed to movement. After the movement testing the firestop system is required to pass the fire test. In any of these events the movement is not considering the direct impact from blast or high winds. A firestop system subjected to movement prior to the fire exposure may not perform as intended, which is why it is important to have a method to test in the event of movement.”

This worker is applying Hilti North America’s new CFS-TTS MD Top Track Seal, a preformed firestop solution designed specifically for metal deck construction. (Photo courtesy of Hilti North America)

NFPA Developments

Quincy, Mass.-based National Fire Protection Association (NFPA) does not endorse, test or certify products, but it has new projects and additions to its existing codes and standards relevant to the metal construction industry. And, NFPA’s Fire & Life Safety Ecosystem is a framework that identifies the components that must work together to minimize risk and help prevent loss, injuries and death from fire, electrical and other hazards. “The metal construction industry plays a big part in [this],” says Tracy Vecchiarelli, PE, principal fire protection engineer at NFPA. “The metal construction industry is leading the way by keeping up-to-date with the latest codes and standards, providing training and education for your stakeholders, and prioritizing safety.”

The NFPA Fire Test Committee has been working on “NFPA 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components,” which addresses fire testing of exterior wall assemblies. The standard requires testing of complete assemblies in order to pass NFPA 285. “The committee is working to develop guidelines for qualified engineers to follow when performing engineering judgments based on expanding existing test data to wall assemblies that contain changes in materials,” Vecchiarelli says. “The committee is presently discussing these new draft guidelines.”

Karns says NFPA 285 is used for multistory wall assemblies, and now includes joints and seams in specified locations or may require replication of the design in the field. “[However,] NFPA 285 is not required for single-story automatic sprinklered buildings (exception within the code). This is a requirement in Chapter 26 IBC, foam plastics, but is inclusive of products such as metal composite material panels, high-pressure laminates, and insulated metal panels.”

The NFPA Fire Test Committee is also working with a task group to develop a new fire test standard for exterior walls. Vecchiarelli says the new test is based on the 16-foot parallel panel test in FM Approval 4880 and represents an exterior wall being exposed to a severe exterior exposure. Also, the NFPA 5000 Building Construction and Safety Code is undergoing revisions for the 2021 edition, including limits for the use of metal composite material (MCM) systems that have not shown compliance with NFPA 285 to 40 feet above grade. “This coordinates the allowable use of MCM systems with the other various codes used in North America and provides a specific height where NFPA 285 is required, rather than a series of minor exceptions,” Vecchiarelli adds.

(Photo courtesy of Tobias Rehbein from Pexels)

As a proactive response to the events involving MCM assemblies around the world, the MCM manufacturer members of Chicago-based Metal Construction Association submitted a code change proposal to the International Building Code 2018 Code Development–Cycle A. This code change proposal was simplifies the code with respect to the use of MCM assemblies making it easier for designers and code officials to understand whether fire retardant or standard core MCM is required for a specific application. This code change has been approved by the Fire Safety Committee with no opposition. This proposal eliminates Section 1407.11 (2012 IBC), which is 1406.11 (2018 IBC), and requires that any MCM assembly installed higher than 40 feet above grade must meet the performance requirements of NFPA 285. While this proposal must still complete the ICC code change process; if approved, it will be incorporated into the 2021 IBC.

NFPA has recently published a new standard to address energy storage systems (ESS) to help address the issue of lithium-ion battery storage systems. NFPA 855, “Standard for the Installation of Stationary Energy Storage Systems,” contains requirements for protecting all energy storage systems including battery installations. “These facilities typically include an arrangement of tightly packed cells stacked on racks,” Vecchiarelli says. “The standard’s main objective is to limit a fire, should it occur, to a single rack, preventing the fire from spreading to adjacent racks. If a fire jumped from rack to rack it could potentially burn for a considerable amount of time, overwhelming sprinkler systems.”

Similar to these racking concerns, new fire safety updates are adapting to new developments in the functions of industrial sector buildings. “Increased ability, reliability and range of automation, and refined or even disruptive distribution models employed by large online retailers have pushed the development of building envelopes for higher storage and larger buildings,” says John Koury, architect, A M King, Charlotte, N.C. “With automated picking systems, we are seeing higher racking, higher density and narrower aisle widths since it is no longer dictated by forklift maneuvering dimensions. Alternative sprinkler applications beyond Early Suppression, Fast Response (ESFR) with wider implementation are gaining acceptance. Obviously, fire is a risk to safety and there can be reluctance to adopt new approaches, beyond what has been proven as a standard. But high-volume, deluge systems are being evaluated and accepted for an increasing number of jurisdictions. This path is not always well traveled, but with coordination, fire marshals can evaluate these systems and adopt them to accommodate the new building dimensions.”

With automated picking systems, there’s an increase in higher racking, higher density and narrower aisle widths since it is no longer dictated by forklift maneuvering dimensions. Alternative sprinkler applications beyond ESFR with wider implementation are gaining acceptance. (Photo courtesy of A M King)

MBMA Releases Fire Safety Results

MBMA recently released the results of a study on fire protection alternatives for metal buildings. The research report, “W/D Study of Non-prismatic (built-up) I-shaped Framing Members in Metal Buildings,” was undertaken by Nestor Iwankiw, PE, SE, Ph.D., of Jensen Hughes, Baltimore.

“This research fills in an important gap in fire protection data for metal building systems,” says Lee Shoemaker, Ph.D., PE, MBMA’s director of research and engineering. “It demonstrates that alternative fire protection materials and products can be specified to accommodate various architectural schemes.”

When fire protection of metal building frames is required by the building code, the assemblies have historically been gypsum board enclosures, such as UL Design No. X524. For this study, 180 single-story metal building designs that varied in span length, roof slope and location in the continental United States were tested. The weight-to- heated-perimeter ratio (W/D) values of the rigid frame members were determined for the metal building designs.

The study results indicate the opportunity for increasing applications of spray-applied products and intumescent/mastic coatings in metal buildings for specified structural framing members. The results encourage alternative potential uses of spray-on protection in industrial or warehouse metal buildings when a finished interior appearance with gypsum board is not necessary. The project was undertaken under the auspices of the MBMA Fire & Insurance committee.

New Fire Safety Products, Materials

There have been updated and new fire safety-related products and materials introduced in recent years that affect metal construction. Mineral wool has been a mainstay building material because of its non-combustible, fire-resistant properties. In 2019, Owens Corning introduced the expanded Thermafiber RainBarrier High Compressive portfolio of mineral wool products. Owens Corning has expanded its Thermafiber RainBarrier Continuous Insulation (ci) portfolio to include a full range of high compressive strength products. “New additions to the Owens Corning Thermafiber RainBarrier ci family help architects match the compressive strength of the mineral wool continuous insulation to the requirements of the façade,” Ogino says. Using ThermaCrimp technology, these new products offer a high-compressive strength mineral wool, which is both thermal-efficient and non-combustible. “These products can be used behind any cladding system including combustible and open joint,” Ogino adds.

Gypsum board products have long served as a protective barrier to structural elements in metal building designs such as structural steel and cold-formed steel framing. “Gypsum board is the most commonly used fire protection material in metal buildings,” says Jonathan Humble, FAIA, NCARB, LEED AP BD+C, regional director at the American Iron and Steel Institute (AISI), Washington, D.C. “New types of gypsum boards are also coming into the construction market, aka specialty boards, that are mold and moisture resistant as well as impact resistant.”

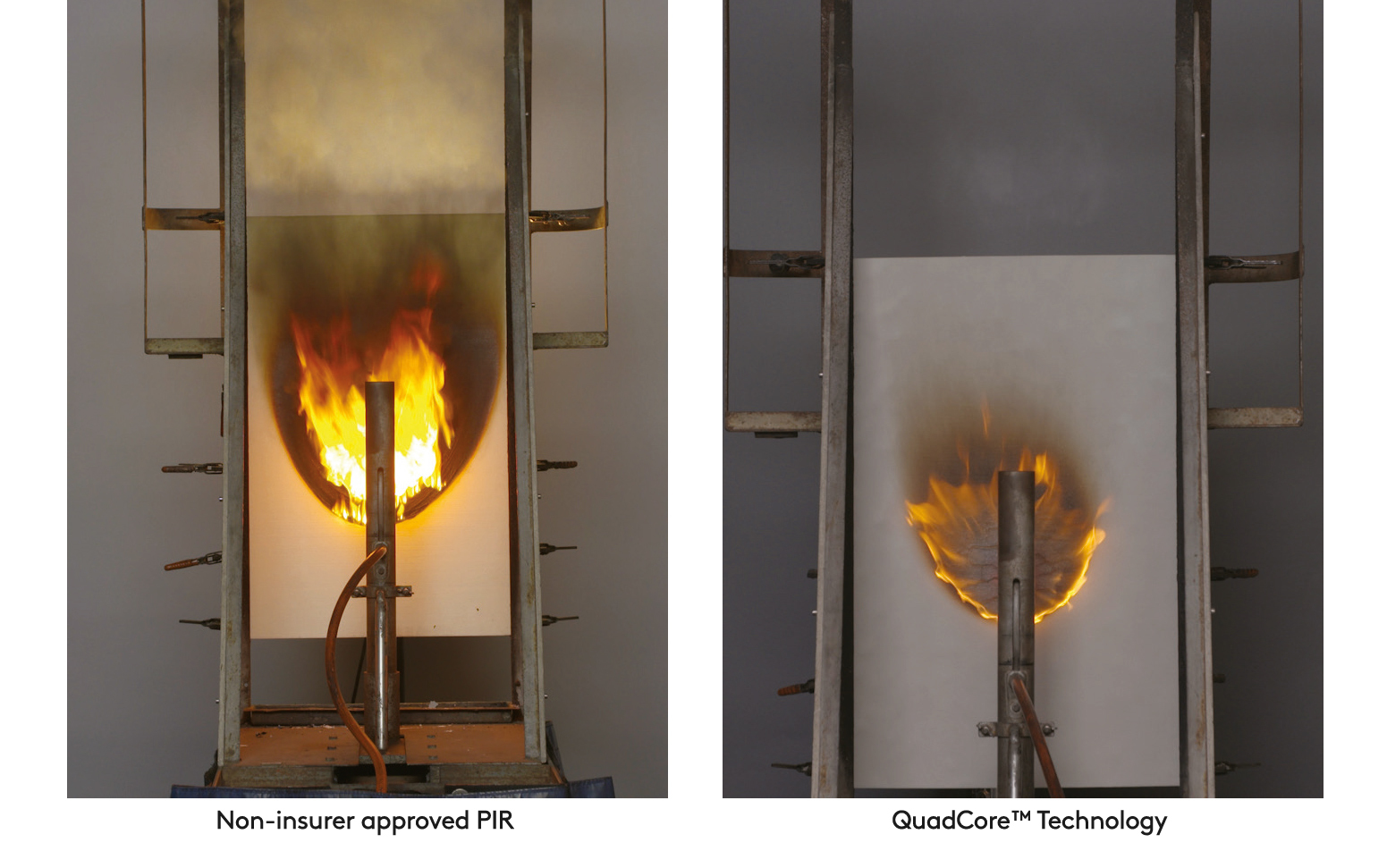

Kingspan Insulated Panels’ QuadCore Technology metal panel insulation has reduced flame spread. (Photo courtesy of Kingspan Insulated Panels)

Spray-applied, fire-resistant materials are also commonly used on structural steel elements. The composition primarily consists of either mineral fiber or cement-based products that protect structural steel through insulation. “New trends in spray-applied materials is an increased in durability (e.g., water, ultraviolet light resistance, exterior environment, freeze thaw effect, etc.), which comply with standard UL2431 ‘Standard for Safety–Durability of Fire Resistive Coatings and Materials’ and higher adhesion-cohesion bond strengths,” says Farid Alfawakhiri, Ph.D., PE, regional director at AISI. “These new products are useful for those buildings housing occupancies like manufacturing, storage, research, etc.”

Kingspan Insulated Panels Inc., Deland, Fla., recently launched QuadCore Technology technologically advanced metal panel insulation. Its improved thermal performance means it is safer in the event of a fire. Brent Trenga, Kingspan’s building technology director, says its class-leading R-value of R-8.0 per inch means it’s certified as the most thermally efficient closed-cell insulation core on the market. “Kingspan insulated metal panels with QuadCore are the first closed-cell insulated panels in the world to achieve FM 4882 certification. This technology [has] reduced flame spread (ASTM E84), higher flash ignition temperature (ASTM D1929) and 20% less heat released (ASTM 1354).”

Hilti North America’s new CFS-TTS MD Top Track Seal is a preformed firestop solution designed specifically for metal deck construction. “Top Track Seal CFS-TTS MD is a firestop, smoke and sound seal for head-of-wall joints between top track and gypsum to corrugated metal deck slabs and metal roof decks,” says Joshua Close, Hilti’s product manager, Firestop. “Designed as a flexible solution for various track sizes in all applications in metal deck construction, it eliminates the need to stuff and spray head-of-wall joints. Saddle the track with it, attach it, and fill the flutes with its preformed plugs or covers. No messy caulk, spray or mineral wool and zero waste.”

To assist façade contractors, Hilti’s QuickSeal: CFS-EOS QS is a new preformed solution for edge of slab and curtainwall firestopping. Its innovative preformed design prompts easy installation and reduced downtime. Hilti’s Fire Finish 60 is a new, water-based intumescent steel protection product optimized for one-hour applications on interior exposed steel.

Iwankiw notes that overhead fire sprinklers are required by code when a building exceeds a certain size or height based on its occupancy, when the building contains products that are recognized as hazardous, or when the building contains an occupancy that is recognized as hazardous. In the national model code development he sees an increase in their use because of changes to provisions concerning fire areas, hazardous contents, assembly thresholds, shelter rooms, etc.

Mark Chubb is a senior analyst at Portland, Ore.-based Code Unlimited, a minority-owned firm specializing in building code and fire consulting services. He asserts, “Relatively few new products have entered the market in recent years to address structural fire engineering challenges affecting steel construction; however, structural fire engineering methods that allow the introduction of performance-based designs have begun to emerge. Although codes are beginning to recognize advances in structural fire engineering using performance-based design and advanced analytic techniques, acceptance of these approaches by local authorities is likely to take a while to develop. Building codes already recognized alternate methods and materials but these requirements demand applicants to demonstrate equivalent performance. These new techniques are not based on the standard time-temperature curve used to establish the fire resistance ratings in current code requirements. As such, many building and fire officials will be reluctant to accept performance based upon so-called realistic or natural fire curves that include not only faster fire development to peak heat-release rates but also recognize ventilation limits on fire growth and a decay phase as fuel is consumed.”

Alfawakhiri says a list of fire-tested designs specifically developed for typical applications in metal building construction can be found on the MBMA website under “Fire Protection.” “Here the user can review the table of tested designs to choose the most appropriate for the project building, as well as conveniently gain direct access to the UL-rated assembly design by clicking the alpha-numeric design number,” he says. “Of course, the entire database of UL and other fire resistance rated assemblies is also available as a resource for use of other products, materials or systems that are not covered within the more limited MBMA subset of assemblies.”