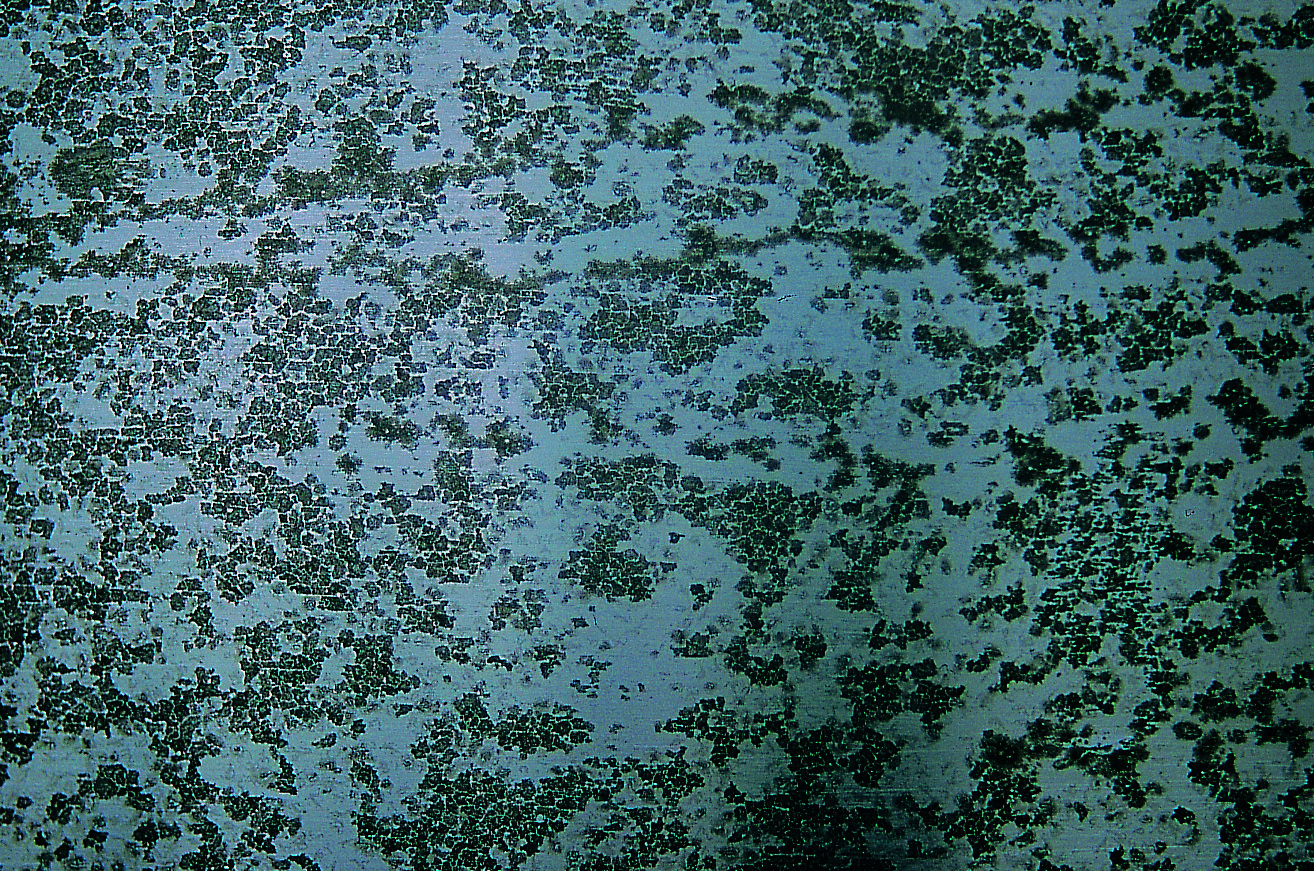

Zinc is a versatile solution for innovative design. Zinc’s durability provides a long-term, natural aesthetic that requires little to no maintenance over the course of its life. Often considered a living material, the toughness of zinc comes from its inherent ability to form a protective coating on the surface, known as the patina. This crust (patina) forms over several years after repeated cycles of wetting and drying—combining carbon dioxide from the air with water to create zinc carbonate (or zinc chloride in a maritime environment). The patination process makes zinc a self-healing material (that’s right)—it heals itself when scratched by regenerating the patina so scratches blend and eventually disappear.

Architects and installers are benefiting from the look, durability and flexibility of zinc

And since zinc is non-ferrous, it won’t rust like other metals. Its corrosion-resistant properties and its low to no maintenance over the life of the material are big advantages.

The sophistication and longevity of zinc are unmatched. With proper installation (following the manufacturer’s instructions), a zinc roof and façade can last up to 80 years and 150-plus years, respectively. In fact, many European zinc roofs installed in the 19th century are still in service today, while others with different roofing materials have been replaced many times over. It should be noted that the longevity distinguished here applies to monolithic zinc and not surface-coated galvanized.

In addition to its longevity and healing properties, zinc is easily malleable and can be manufactured in a variety of shapes from compound and convex curves to angled panels. Structures are clad with relative ease due to the material’s characteristic flexibility. And zinc use is not specific to any geographic area. Though temperature may influence how an installer works with the material, it is as comfortable at high altitude in extremes of cold as it is in hot desert or wet maritime environments.

Zinc Profiles

Heavy-gauge zinc rainscreen panels can provide a very long service life of 150-plus years. Using light-gauge zinc cladding may provide an economical alternative, yielding shorter service lives. Light-gauge roll-forming equipment provides an economical way to fabricate interesting panel profiles.

With the ability to alter the orientation (horizontal, vertical or diagonal) of the panel seams, architects and contractors are able to achieve inspiring wall elevations with light-gauge zinc as well. Some of these zinc profile alternatives include: Corrugated. Common sinusoidal profiles have heights of 1/2-inch, 3/4-inch and 7/8-inch with a typical frequency of 2.6 inches. Trapezoidal corrugated profiles for wall applications vary greatly in profile but are deeper/higher (1-inch-plus) in section and provide a stronger shadow effect. Both profiles deliver the zinc sheet with greater rigidity and strength. From a design point of view, the corrugated panels are characterized by the exchange of light and shadow, which will vary depending on the heights of the corrugation.

Standing Seam. Vertical standing seam pans using the single-lock or double-lock seaming method have a long-standing history for roof applications. Commonly used on facades, this application exhibits strong linear shadows produced by its angle configuration. Using this profile on the wall surface with seams oriented horizontally (or vertically for shorter panels) makes a very cost-effective zinc cladding. Given the optimum drainage plane, the single-lock (or angled-seam) installation method is preferred to allow maximum horizontal panel movement.

Flush/Reveal Panels. Architects looking for a monolithic natural gray wall with minimal shadow lines often choose a flush (hairline joint) panel. Similar profiles with extended male lateral edges will create a reveal or recessed seam (up to 1 inch). Both profiles can be installed in a horizontal or vertical orientation. Shorter panels can be through fastened at the bottom female s-lock joint.

Interlocking/Flat-Lock Tile. Flat-lock wall tiles provide an easy-to-install, dry-joint wall cladding solution. Interlocking tiles are a common profile choice with many sizes, shapes and patterns of orientation. Flat-lock tiles offer numerous design options. Interlocking tiles can be fabricated into various shapes including: rectangles, squares and diamonds. The time required to cut, notch and fold interlocking tiles makes them more costly to fabricate than the roll-formed profiles.

Charles “Chip” McGowan has been the president of RHEINZINK America Inc., Woburn, Mass., since 2010. Having been involved with the distribution of natural metals for over 30 years, McGowan’s specialty is in manufacturing, sales, and technical advisement. Richard Strickland is a RHEINZINK regional sales manager for Canada. Strickland has extensive hands-on knowledge of the metal building’s industry. Strickland can be reached at richard.strickland@rheinzink.com. To learn more, visit www.rheinzink.com.