Most shops keep their press brakes and/or folders operating steady, when they have someone to operate the machines. There’s always a need for a wide variety of trim pieces used to complete the construction of metal buildings. Ridge caps, sidewalls, end walls, corners, rakes, J-channels and gable trims are just some of the trim pieces routinely required on metal building projects. It’s a tough job.

Offering speed, flexibility, less labor and improved accuracy

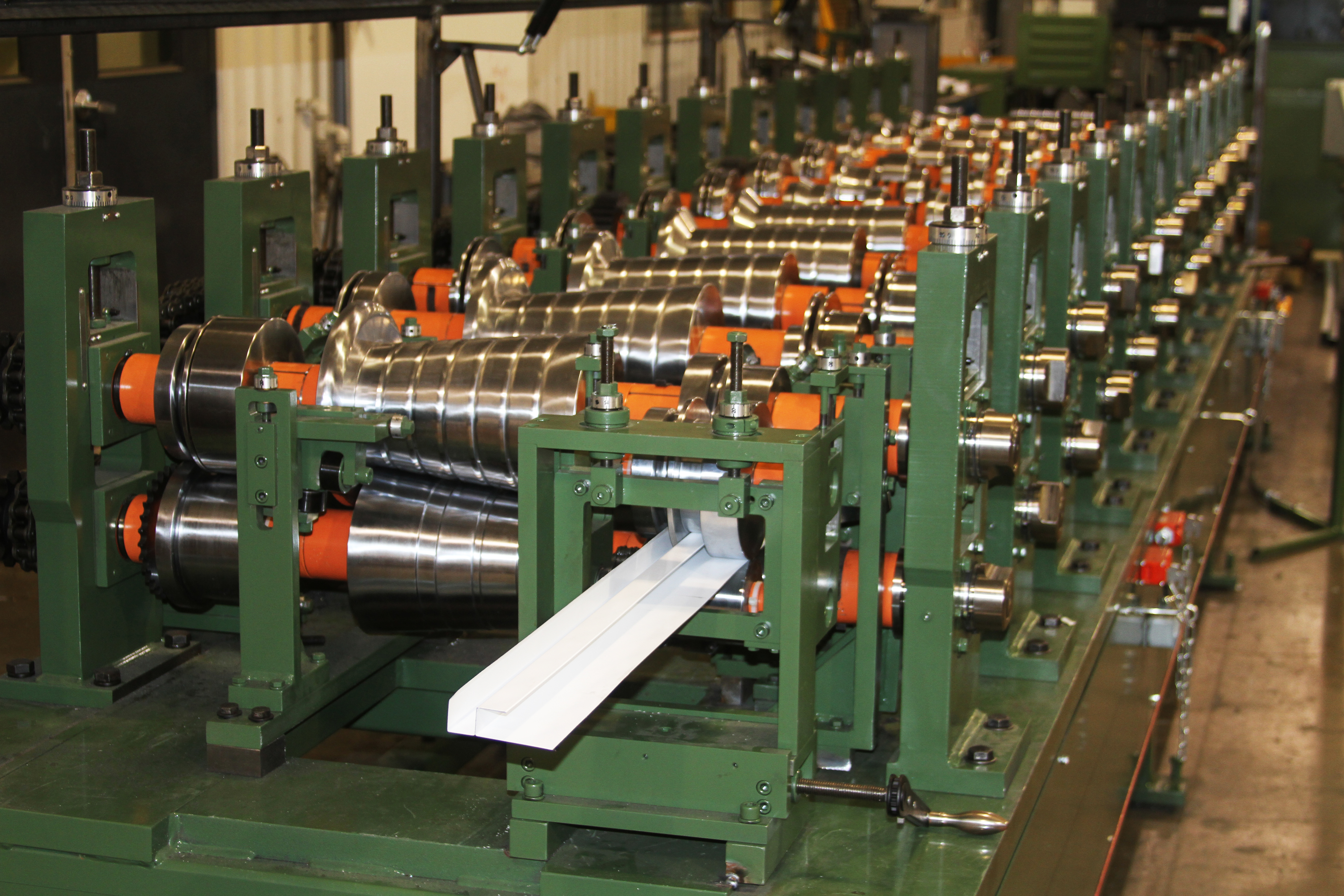

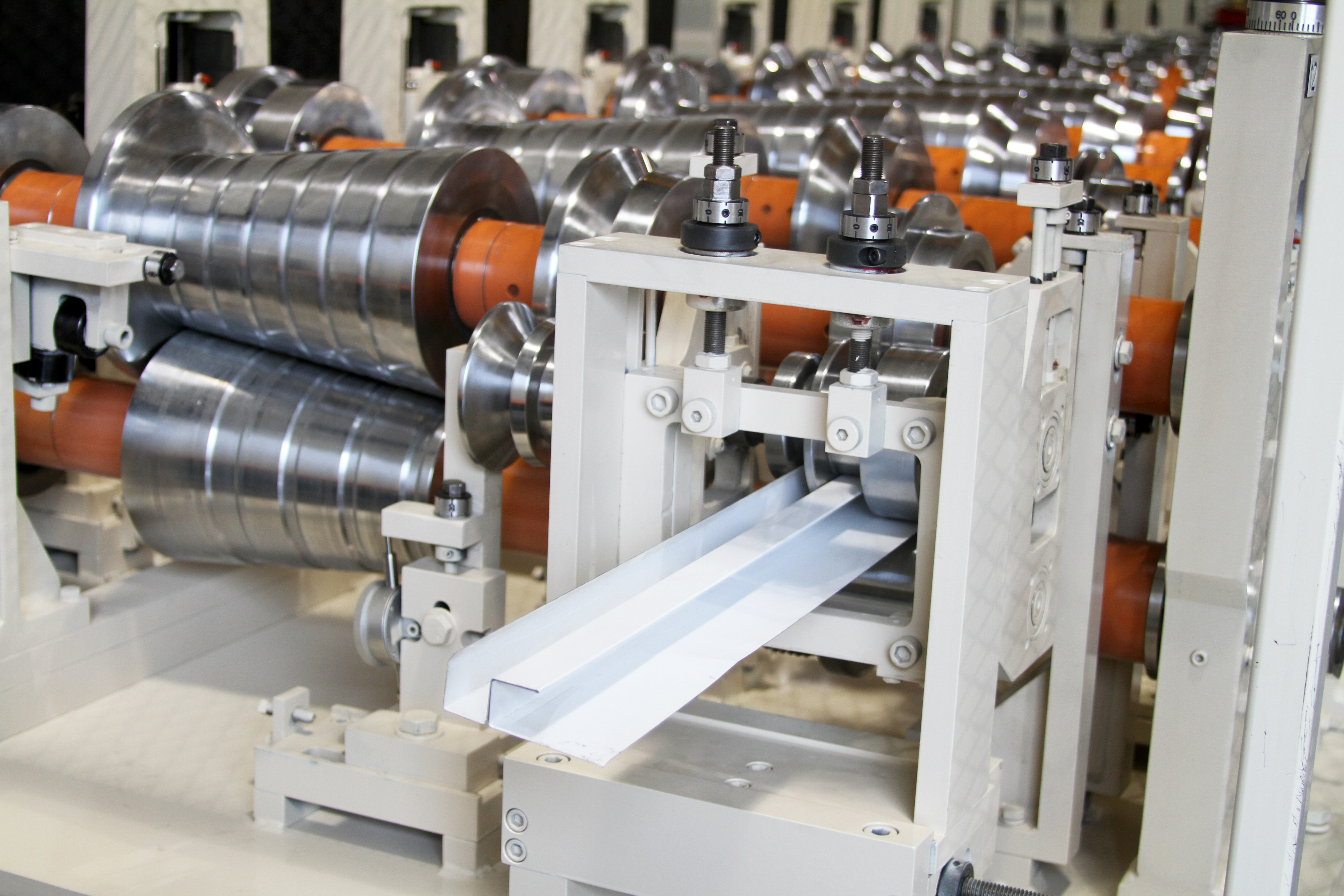

Because it’s become a growing challenge to find and keep skilled labor to operate a press brake and produce high quality pieces, many shops are considering a transition from brakes and folders to using a multiprofile trim rollformer. A multi-profile rollformer offers efficiency and improved accuracy, as well as ease of operation.

Flexible versus Dedicated

Once you make a commitment to purchase a multipurpose rollformer, you have to determine which is best for your operation: a flexible trim rollformer or a dedicated rollformer. Both machines require an operator to hand-feed material, material that is already cut to a desired length.

Flexible trim rollformers are supplied with combination and fixture heavy tool sets. Standard wide combination trim shapes include big and small rake/ corner trims, big and small ridge cap trims, and big and small eave trims. Some examples of industry standard narrow combination trim shapes include rat guard/double angle trims, big and small J-channel trims, and beaded/smooth variable cover post trims. Examples of fixture heavy trim shapes include F and J trims, F-channel trims, drip edge and overhear door trims. Flexible trim rollformers can be designed to process two types of material.

Dedicated trim rollformers are typically supplied with two industry standard wide shapes and two industry standard narrow shapes. Some examples of industry standard wide trim shapes include universal corner, universal ridge cap, rake/corner, gable trim, gable trim, fascia trim, universal sidewall, universal end wall. Some narrow trim shapes are base angle, J-channel, double angle and drip cap. Dedicated trim rollformers are designed to process a single grade of material.

Both dedicated and flexible trim rollformers offer material savings for some pieces. As an example, a J-channel formed on a brake will requires a 4 1/2-inch girth with a 1/2-inch hem. With a rollformer, you can form the hems at a 1/4 inch. A 48-inch master coil will produce 10 J-channels on a brake, while a rollformer will allow for 11 J-channels, with minimal scrap.

Volume and Return on Investment

The flexible rollformer is capable of producing multiple shapes with flexible tool sets, while the dedicated rollformer features dedicated over form passes for each tool set. Handfed trim rollformers provide repeatability and reduce operator fatigue while providing production capabilities of 10 parts per minute.

Ultimately, the decision to purchase and transition to a trim rollformer comes down to volume. Shops considering adding a brake and hiring another person or two, are likely ready to add a trim rollformer and use the employees they have in place as operators and making them part of a more efficient shop. Adding labor has been an increasingly challenging task.

Figuring out your return on investment will have to take into consideration that for most trim pieces, a rollformer will produce pieces eight times faster than a brake. The difference will be greater for trim pieces with more complicated and tighter folds. Simply, a trim rollformer will produce more consistent and high-quality pieces in a much greater volume than a brake.

Ben Schmidt is the industry sales manager–metal buildings, trim and decking at The Bradbury Co. Inc., Moundridge, Kan., where he manages all facets of sales and customer relationships in the metal building, decking and trim shop industries. To learn more, visit www.bradburygroup.com or call (620) 345-4332.