When a customer calls, they answer. Being available when customers, or potential customers, want to communicate has given AARA Construction Inc. in Gilbert, Ariz., a competitive advantage.

Fabricator, installer finds growth through easy communication and strong relationships

Kathy Stowe, controller, Angelica Merrill, project coordinator, Jerry Spores, president, Brad Wilembrecht, estimator, Jesus Andreas Ortiz, draftsman, and Ismael Fuyivara, engineering manager.

Jerry Spores, president at AARA Construction, says, “I think a lot of our success has to do with the personal involvement in each project and answering the phone when somebody calls. I’m adamant to have somebody with a voice answering the phone rather than have robotics. Nowadays, you obviously have a cell phone, so picking up the phone and being available has been a key to success.”

To install insulated wall panels on a 96-foot-tall parachute drying tower at Davis Monthan Air Force Base in Tucson, Ariz., AARA Construction employees used two lifts and a crane.

Access is Key

With so many ways to communicate these days, at first, it might seem counterintuitive that assuring customers a person will answer the phone when they call, or respond via digital means, would be advantageous in an always competitive construction market. But it turns out, Spores says, not all companies do that, and it can mean the difference between building a relationship with a potential or existing customer, or losing that opportunity.

“I think in the digital world we live in now, when everybody wants to email, then waiting for a response can be frustrating. Being involved and available really resonates with the personal involvement,” Spores says.

AARA Construction installed insulated metal panels on Navajo Technical University’s instructional building in Chinle, Ariz.

Spores’ focus on building long-lasting relationships with people in the construction industry has been the cornerstone of AARA’s growth. Spores started at the company in 1992 doing drafting, estimating and, eventually, project management. When owners Sue and Larry Garberick retired in 2006, Spores and Tom Weihmummler, another AARA employee, bought the company. In 2016, Weihmummler retired, and Spores bought the whole company.

Spores was part of the company as it grew from doing primarily residential room additions to the large commercial and industrial projects it does today. When he started at the company, there were 14 or 15 employees, and annual revenue was about $3 million. Today, almost 50 people work at AARA, and annual revenue is about $9 million.

“The way we operate here, me being president doesn’t mean I’m not available to go to a pre-bid meeting or drive to inspect a finished project,” Spores says. “When we receive a warranty call, I answer the phone in the same fashion as somebody that just handles warranties or just handles bidding.”

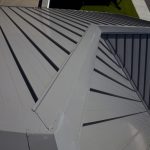

For roofing on the town of Gilbert, Ariz.’s fire station no. 9, AARA Construction rollformed continuous length panels.

Spores says experience and knowledge he and his employees have gained over the years helps them communicate with architects. “When [architects] call for a reference and describe what they want to build, we’ve got some knowledge and experience that we can convey what we’ve done on previous projects, and that really helps.”

Francisco Casteel and David Villalobos fabricate custom sheet metal flashings in AARA’s shop in Gilbert, Ariz.

Work, Labor Balance

In addition to the company’s focus on being accessible and communicative, Spores says another key to its longevity and growth has been constantly trying to balance the amount of work they commit to with the amount of field installers employed.

“When you think you can’t take on more, you find yourself a little short. Sometimes you find yourself dealing with too much. So it’s a difficult balancing game you put yourself in many times. Work flow is the more stressful part of running the business. I don’t have all answers, but we do try to attract quality installers and keep them busy. Once you attract a few good people, they typically bring a few more onto the team, and it basically develops a slow growth rather than fast-paced.”

In addition to balancing projects and labor, Spores says the type of work AARA does has evolved over time. In the beginning, the company primarily did residential room additions. In the 1990s, military projects including metal roof retrofits were a big part of the company’s business. In more recent years, commercial and industrial projects with metal roofs, metal walls and metal composite material make up its portfolio.

AARA fabricates its own roof and wall panels for projects. Spores says one of the pivotal points in the company’s history happened early on, when it began using portable rollformers. “[The Garbericks] had the foresight to buy a rollformer. The benefit to the portable rollformer is continuous lengths when you’re talking metal roofing,” Spores says. “That’s been a big factor for us in being able to run continuous lengths on projects. That’ll win you a project.”

Keeping Up with Tech

Spores says it’s essential for his company’s success to continue to change its practices to meet the needs of customers in an industry that constantly changes. Keeping project management software up to date and employees trained to use the latest tools is part of maintaining AARA’s growth, Spores says. “In the construction industry itself, we’ve seen the industry changing, digitizing everything. The technology is definitely changing in the way [architects are] modeling and designing. We now see big flat screens on the job site. Some of the younger generation is moving forcefully into our industry and you have to speak their language with technology. You have to know the industry is changing and move with it rather than try to fight it.”

Jerry and Sindi Spores, owners at AARA Construction.

Jere Betoney, John Single, David Villalobos, Joe Abeita, Francisco Castillo, JJ Single and Jarett Spores.