One of metal roofs’ best benefits is their longevity. Metal roof panels have baked-on OEM coatings or finishes for aesthetic or functional reasons. But these coatings may deteriorate, become damaged or fade over time, possibly leading to building leaks, corrosion and energy efficiency problems. The good news is recoating metal roofs with a variety of special materials means the entire roof doesn’t need to be scrapped and replaced.

When done correctly, a quality coating system can extend a metal roof’s life cycle

Mule-Hide’s A-300 Finish Acrylic Finish Coating is being applied with a sprayer. (Photo courtesy of Mule-Hide Products Co. Inc.)

Gary Edgar, national coil and extrusion specification manager at Pittsburgh-based PPG Industries Inc., explains roofs are recoated before the intended service life expediency for three primary reasons: aesthetics and color, mechanical and storm damage, as well as environmental conditions that cause corrosion and premature failure, especially without a regular cleaning routine. “In terms of color and aesthetics, roofs are typically recoated because the owner, corporation or school decides the roof color is no longer current. Mechanical and storm damage can fracture the coating film and system, leading to premature failure and usually includes damage during the original installation and installation of new equipment on an existing roof. Hail and flying debris can also fracture the coating system, and if left unchecked, can lead to delamination of the coating system. A harsh or aggressive environment will attack a coating system much faster than a mild environment, thus requiring more cleaning to keep the corrosion and chemical attacks at bay. The coating system will begin to fail if a proper maintenance routine is not in place in these environments.”

Doug Loomis, vice president of Energy Coating Systems Inc. (ECS) of Conroe, Texas, says, “We are always first and foremost called because of leaks and/or rust, mostly on roofs 20-30 years old and some earlier. Generally, leaks and rust always start with the fasteners. A properly applied high-grade coating system that addresses these problems can turn the any roof into a sustainable roof.”

Recoating a metal roof is typically a fraction of the cost of a complete roof replacement. Roof coatings can be applied in half the time of a new roof installation and they reduce the disruption of building tenants.

Coating Application

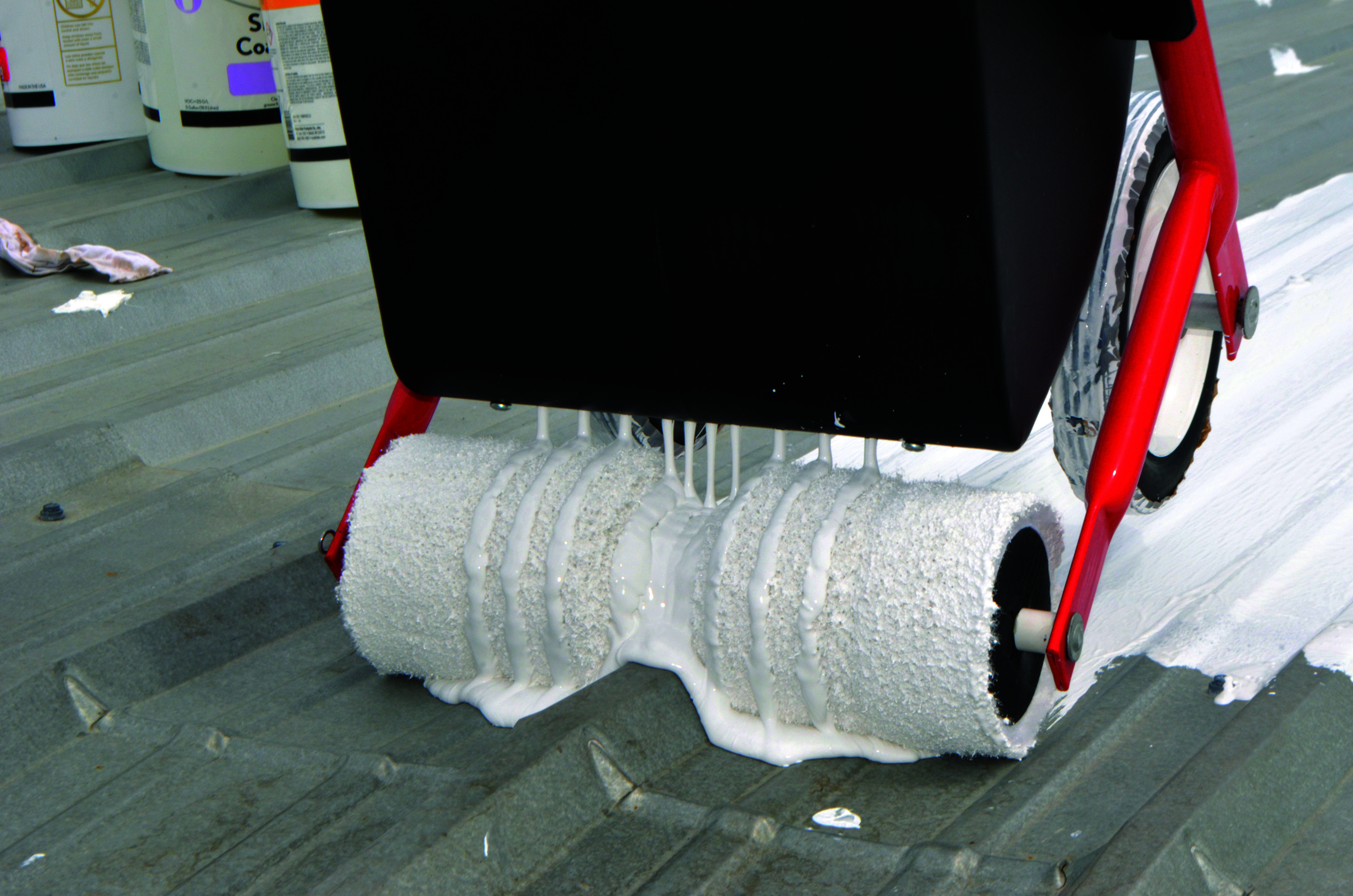

There are many ways to apply coatings to metal roofs, the most common being spray application and roller application. The best method for a particular project will be determined by the specific conditions presented, including slope, panel profile and coating type.

Recoating a metal roof can make it look new again. (Photo courtesy of Energy Coating Systems Inc.)

“Spray application requires heavy-duty, professional-grade spray rigs designed and intended for roof coatings,” says Jeremy Grunewald, product category manager—liquid-applied systems, Mule-Hide Products Co. Inc., Beloit, Wis. “These spray rigs typically have higher output and pressure capabilities at the pump than you’ll find with a traditional paint or coating sprayer that can be found at a big-box retail or DIY store: 4,500 psi or 7,250 psi compared to less than 2,000 psi. The higher pressures and outputs allow for greater production efficiencies and faster application speeds, which are critical factors for contractors.”

Jeff Stephens, brand manager at Rust-Oleum, Vernon Hills, Ill., agrees the vast majority of metal roof restorations are applied using roofing spray rigs designed for roof coatings. “The airless spray rigs allow for a much more uniform application of product at specified coverage rates over irregular panel surfaces in addition to increased productivity.”

Grunewald explains roller application may require paint rollers, brooms, brushes, squeegees or other manual application tools. “The type of coating, application rate and desired finish of the coating will determine the appropriate roller nap thickness—i.e., 1.25-inch nap or 1.5-inch nap—and roller head material type: synthetic fibers or foam.”

Contrasting the two application techniques, Edgar explains an airless spray application resembles the original factory application, while roll application typically has a slight texture, which may or may not be acceptable to the owner.

Metal roof restoration coating system. (Photo courtesy of The Garland Co.)

Ed Buczek, senior product manager at The Garland Co., Cleveland, contends airless spray equipment is very useful for covering the underside of metal roof vertical seams. “That detail is difficult to do well with rollers and brushes. Spraying a metal roof is usually quicker than roller application and coverage rate more controlled. However, there are tank spreaders for metal roof application now available that can rival the speed and effectiveness of spraying without overspray concerns and spray equipment cleaning/maintenance.”

Recoating Errors

Inadequate surface preparation and improper identification of the existing coating or substrate are common mistakes when recoating metal roofs. The long-term performance of coatings in metal roof restoration depends on the coating’s ability to tightly adhere to the metal roofing surface.

“Inadequate surface preparation can leave behind dirt, debris, grease, oil or loose rust, which can reduce the coating’s ability to adhere to the metal roof,” says Grunewald. “Over time, a poorly adhered coating may begin to peel, crack or blister, causing not only unsightly aesthetic concerns, but also creating the potential for water to penetrate between and underneath the coating and the metal roof. This can, of course, result in roof leaks or cause the coating to further crack, blister or peel. Improper identification of the existing coating on the metal roof may also lead to similar coating adhesion concerns due to inadequate bonding between the new coating material and the existing coating.”

Stephens contends 90% of all metal roof recoating failures are due to inadequate surface preparation, and that properly preparing corrosion areas and in some cases, priming is a must. “The project always needs to address the cause of leaks and the details of the restoration which vary project to project. Once all flashing and detailing conditions are completed, the coating restoration will have a higher success ratio compared to just applying a restoration coating.”

Edgar agrees that improper metal roof surface preparation and wrong product recommendations are common mistakes when it comes to recoating metal roofs. “Mock-ups are a great way to ensure proper adhesion and owner satisfaction.” Buczek says a common recoating mistake is poor flashing detailing, specifically at horizontal panel overlaps and any internal drains. “It’s imperative to provide fabric reinforcement and high-performance sealers in these areas of greatest strain on a metal roof where a coating alone will eventually fail.”

Recoating a metal roof. (Photo courtesy of Rust-Oleum)

Loomis says he has seen many poorly applied coating applications over the years and that it always boils down to poor quality workmanship. “Pay attention to the details and the outcome will be as expected. I have seen as many metal roofs installed improperly as coating systems. The outcome is always the same: failure to live up to desired results and an unhappy customer. No matter what roof or coating system you are installing, follow manufacturers’ recommendations and pay attention to details.”

Correct Recoating Material

Selecting and using the correct material is imperative for recoating roofing. Stephens contends not all roof coatings are right for every roofing type. “Silicone roof coatings tend to have low corrosion protection. Contractors and building owners should look at coating metal roofs with aluminum, urethane and some elastomeric roof coatings to deliver long-term performance. Rust-Oleum has developed a Premium Elastomeric 880 that is a single component, rust preventive, water-based acrylic elastomeric roof coating. The self-priming, high build coating is designed for use on tightly adhered rusted surfaces or clean steel. The excellent elongation properties of over 500% make it suitable for bridging small cracks.”

Grunewald explains roof coating span a wide variety of technologies and chemistries from water-based to solvent-based technologies and moisture-cured to evaporative-cure chemistries. “For most common applications of roof coatings, there may be differences in procedures such as surface preparation or the use of a primer. We recommend that the manufacturer’s installation instructions, procedures and specifications be followed whenever applying a roof coating.”

Mule-Hide’s 100% Silicone Roof Coating is being applied with a roller. (Photo courtesy of Mule-Hide Products Co. Inc.)

Over the past few decades, there has been a large shift and trend in the commercial roofing market toward white, reflective, cool roof coatings. “The roof plays a critical role in the transmission of heat into a building, thanks to its size and direct exposure to the sun,” Grunewald says. “The heat from the sun raises the roof’s surface temperature, and that heat then transfers to the building’s interior. This then puts greater demand on HVAC units to maintain hospitable conditions in the occupant spaces. White, cool roof coatings have high reflectivity and emissivity, meaning they keep the rooftop cooler and then expel much of the heat that does enter the building.”

Edgar explains these reflective coatings are becoming more mainstream, “Especially with the environmental focus on carbon footprint and saving energy. These pigments show real value with darker colors, whereas lighter colors reflect heat more naturally.”

Loomis notes all coatings are climate sensitive and that there are temperature ranges and rain chances to consider. “Yes, many regions have adopted requirements for a certain energy-saving quality to their roof surface. Any white paint/coating will have a reflective quality, but the greatest advantage is in the emissivity quality of most coatings. Important to metal roofs is the reduction in thermal shock.”

Grunewald says that like many building and construction materials right now, costs and lead times for metal roofing systems have gone up significantly in recent months. However, “Coating systems for fluid-applied roof restoration and recoating are currently providing lower costs and significantly faster lead times. If a property manager hasn’t considered recoating their roof as a restoration option, now may be the optimal time.”