Roll forming production of metal roof panels, wall panels, wide-coverage panels and other supporting items has evolved dramatically in recent years to provide more options, and a lot more production control, to contractors and installers.

Digital, portable and more automated than ever

As recently as 15 years ago, because of limited profile options, product quality and the requirements of architects and/or regulatory officials, many contractors purchased rather than produced the panels they needed. This path came with some limitations, including long lead times and often a need to over-order material to ensure the job could be completed.

The construction industry today is facing a difficult shortage of skilled workers. To help meet this challenge, advanced roll forming machines have made it possible to produce more product, and do it more quickly, with fewer people.

A New Path

Today, digital measurement and an increasingly automated production cycle represent the new path. For example, in producing roof panels at a factory, or on the job site with a portable roll former, you must have as-built measurements to make the product fit properly. Technology now exists where you can overfly a building with a drone, capture the roof lines on video, feed the data into a computer program, get all the exact measurements, input that data into a roll former and make parts that will perfectly fit your hips and valleys.

Customers may go to the web to input data about all the different parts needed for a specific job, whether it’s trim pieces, wall panels, roof panels, fasteners and insulation, whatever it might be. E-commerce sites are at the ready. Fill a shopping cart (even including custom trim shapes) and send that information to the manufacturer. Today’s technology and advances in equipment have allowed contractors to take greater control of their jobs.

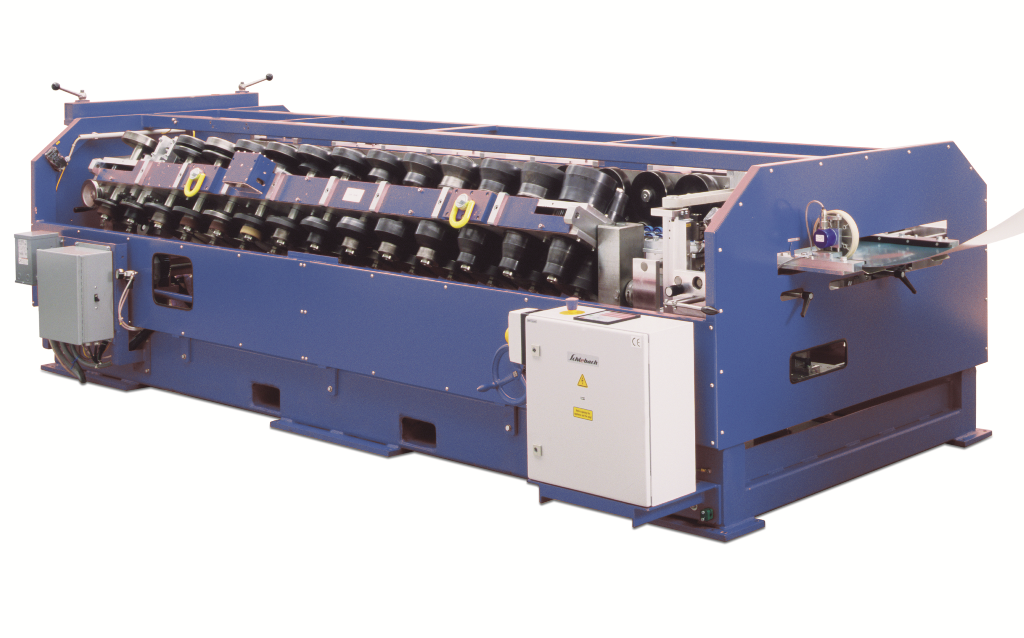

Factory-based roll forming continues to be a huge provider of roof and wall panels. Strong factory partners provide a high level of assurance and product quality guarantees that many contractors find comforting. Some builders don’t want to own the responsibility for on-site production. But today, partnerships also may be formed that utilize a combination of factory-produced panels that are shipped to a job site, as well as on-site production of panels in, say, long lengths, all of which help enable a seamless installation.

On-site Popularity

Roll forming continues to grow in popularity. There are now portable roll formers that meet the UL underwriting required by many architects or building owners, removing a barrier to entry.

And through equipment advances, there are now portable machines capable of producing multiple profiles with a changeover times that have been reduced from hours to minutes, resulting in less waste and faster production.

When deciding on a portable machine, or whether you want a machine, you have to consider what kind of work you are doing, and what kind of markets you want to compete in. For example, in the residential marketplace, the most common profile is the nail strip. If you are a residential contractor and you are only going to make nail strip, you can buy an inexpensive machine that makes one profile and you don’t worry about whether you change it out or not.

If you are a contractor who does a variety of work, you are going to encounter a wide variety of profiles, and you are going to want a machine that change profiles rapidly with no loss in quality. The ability to roll form numerous products continues to grow in the market. Whether portable or in-plant, or a combination, is right for you, the technology continues to evolve at a rapid pace to meet the demands of your next job.

Chad Rowe is automation sales leader at MetalForming Inc., Peachtree City, Ga. To learn more, visit www.metalforming-usa.com or call (770) 631-0002.