Manufacturing a multitude of products across many industries

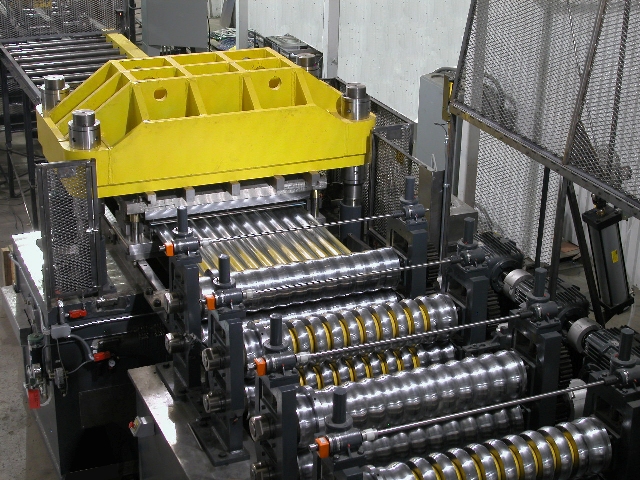

Rollforming is an efficient way to produce formed steel shapes at a high production rate with less labor than many other methods such as traditional press brakes. Moundridge, Kan.-based The Bradbury Co. Inc.’s experience in rollforming began in the 1950s. Recently, we located the very first rollformer we ever manufactured, which was still producing product. It was small enough to fit in the back of a pickup truck and it produced metal awnings that were installed above residential windows. Rollformers can run for decades if properly maintained.

Rollforming is an efficient way to produce formed steel shapes at a high production rate with less labor than many other methods such as traditional press brakes. Moundridge, Kan.-based The Bradbury Co. Inc.’s experience in rollforming began in the 1950s. Recently, we located the very first rollformer we ever manufactured, which was still producing product. It was small enough to fit in the back of a pickup truck and it produced metal awnings that were installed above residential windows. Rollformers can run for decades if properly maintained.

Many technological advancements have happened over the years improving production rates, reducing scrap and increasing operator safety. Sometimes rollformers are paired with other equipment, such as wing benders, robotics, and inline welders, providing even more value. They can be designed to form a wide range of material and thicknesses. Materials that can be rollformed are hot-roll steel

(HRS), cold-rolled steel (CRS), aluminum, stainless steel, galvanized steel, and pre-painted steel, brass, titanium, ranging from a very light 0.009-inch to a very heavy 1-inch-thick. You may be surprised to know how many products you see and use every day are produced on a rollformer.

Metal Buildings

Of course metal buildings are made up of rollformed components including purlins, roof and wall panels and trim profiles. However, some of the less obvious products in buildings which are rollformed are the steel doors and door frames, window frames and garage doors. Sectional steel garage doors are formed, embossed and stamped with different patterns in rollforming lines. Some lines are designed to produce a finished insulated garage door with integrated foaming units, pressure conveyors and flying band saws. Door tracks, struts and other accessories, as well as rolled-up curtains and slat doors, are all rollformed. The agriculture market also is one of the largest markets with products being rollformed.

Many components of a grain storage bin are rollformed. The side walls are formed, punched and curved to make the specific diameter of the bin. The pie-shaped grain bin roof panels are slit diagonally and then rollformed. Grain bin stiffeners and ladder rungs are also a product of rollforming. Agricultural equipment, such as grain harvesters and hay equipment, are made up from rollformed parts. Many of the components are high wear, therefore they are made from heavy gauge and very-high tensile steel, sometimes over 100,000 PSI. Because of rollforming’s progressive forming nature, it is one of the viable solutions to produce these parts.

Steel Framing

In commercial construction, nearly all steel framing components come from rollforming lines. This includes structural cee sections to light-gauge drywall studs and accessories such as furring strips and corner bead. The fast changeovers and highspeed production lines have made rollforming the preferred method of manufacturing in this industry. This is where we tend to see some of the highest production speeds. For example, drywall studs are being produced at 500 feet per minute, that’s up to 50, 10-foot-long studs per minute. Rollformed steel decking in multilevel buildings allows concrete to be poured between floors. Steel racking, office furniture and even elevator components are other products made on rollforming lines. Welded tube lines supply products for many different markets. You can see several examples like fence posts, electrical conduit, exhaust pipe and structural tubing like what is used in carports.

In commercial construction, nearly all steel framing components come from rollforming lines. This includes structural cee sections to light-gauge drywall studs and accessories such as furring strips and corner bead. The fast changeovers and highspeed production lines have made rollforming the preferred method of manufacturing in this industry. This is where we tend to see some of the highest production speeds. For example, drywall studs are being produced at 500 feet per minute, that’s up to 50, 10-foot-long studs per minute. Rollformed steel decking in multilevel buildings allows concrete to be poured between floors. Steel racking, office furniture and even elevator components are other products made on rollforming lines. Welded tube lines supply products for many different markets. You can see several examples like fence posts, electrical conduit, exhaust pipe and structural tubing like what is used in carports.

Residential housing is made up of many rollformed products such as metal roofing, metal shingles. gutters, downspouts and roof fascia flashings. Other rollformed products that can be found around the home are washers, dryers and various kitchen appliances. Heating and air conditioning units and hot water heaters were likely produced on system using a rollformer. Many of the steel window wells were also formed and curved in a rollforming line.

Rollforming manufactures a multitude of products across many industries. Advanced automation, operator friendliness, production volume and flexibility continue to make rollforming an absolute viable option in advanced manufacturing.

Matt Werner is marketing manager at The Bradbury Co. Inc., Moundridge, Kan. To learn more, visit www.bradburygroup.com and to see videos, visit bradburygroup.com/Bradbury- Group-Video-Library.