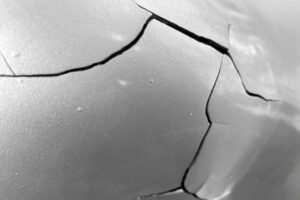

The concept of self-healing materials is a growing field of materials science with profound implications for construction. In metal construction, fatigue, corrosion, and stress concentration remain persistent threats to longevity and safety. However, self-healing technology offers a new layer of resilience.

From high-rise cladding and structural framing to bridge decks and architectural panels, metal assemblies are subject to performance loss from microcracking, thermal cycling, and corrosion. Self-healing innovation promises to mitigate those failure points by embedding repair mechanisms directly into the material system.

The science behind self-healing metals

Self-healing metals use embedded or intrinsic mechanisms to recover structural integrity after damage. They fall into three broad categories:

- Microcapsule-based healing: Microscopic capsules containing healing agents—such as liquid metal or epoxy—are embedded into a metallic matrix. When a crack propagates, it ruptures the capsule and releases the healing agent into the fracture zone.

- Shape-memory alloys: Certain alloys, such as NiTi, return to a predefined shape upon heating. This can close cracks or distortions formed during mechanical stress in some configurations.

- Reversible bonding or grain-boundary engineering: Emerging techniques manipulate alloys’ grain structure or chemical properties to enable atomic diffusion at fracture sites. This allows bonds to re-form over time, particularly under elevated temperatures or stress relaxation.

In a landmark study by researchers at Sandia National Laboratories, a 40-nanometer-thick piece of platinum cracked under cyclic loading and repaired itself without any external stimulus within 40 minutes. The report noted that similar autonomous healing occurred in platinum and copper specimens, pointing toward intrinsic healing behaviors at the nanoscale.

Both platinum and copper are transition metals known for their high malleability, ductility, and favorable grain structures. These traits make them especially suited for testing healing responses at the nanoscale. These properties allow the material to deform without fracturing and facilitate the atomic mobility required for crack closure and self-bonding.

Current applications and pilot projects

Although still in development, early-stage applications and trials have begun. Structural components incorporating microencapsulated healing agents, such as bridge elements and facade systems, have been tested in high-wear environments.

Thermo-responsive coatings embedded with reactive capsules have also been prototyped for parking structures and weather-exposed curtain wall systems. These coatings seal microcracks as heat activates the embedded agents.

Performance standards remain essential during this transition. Powder-coating systems—especially those rated by the American Architectural Manufacturers Association (AAMA)—are central to architectural metal. The new Fenestration and Glazing Industry Alliance (FGIA) now oversees certification under ratings AAMA 2603, 2604, and 2605. These serve as benchmarks for durability and environmental resistance, even as new materials with self-healing capabilities evolve.

Long-term performance metrics of self-healing metals

Evaluating the durability and reliability of self-healing metals involves multiple performance metrics:

- Crack healing efficiency: Laboratory tests on self-healing metal matrix composites reinforced with shape-memory alloy fibers demonstrated up to 96 percent crack closure and flexural strength recovery after damage under controlled fatigue conditions.

- Fatigue life extension: Experiments with NiTi alloys show up to 40 percent increases in fatigue life following activities of internal healing mechanisms.

- Corrosion resistance over time: Metal coatings infused with corrosion inhibitors—such as microencapsulated zinc-aluminum blends—significantly reduced corrosion rates during salt spray testing.

- Mechanical property retention: In a 2024 study, aluminum-silicon composites reinforced with NiTi shape-memory fibers regained approximately 92 percent of their original tensile strength after self-healing cycles during fatigue testing.

- Life cycle cost reduction: Many forecasting analyses show that self-healing materials deliver significant life cycle cost savings through extended service life and reduced maintenance needs.

Benefits for metal construction professionals

The upside is substantial for engineers and contractors. Self-healing systems reduce downtime, inspection cycles, and emergency repairs. Facade systems with innovative coatings could resist damage from hail, salt spray, or freeze-thaw cycles without reapplication.

For developers and manufacturers, these materials support more extended warranties and better building performance under LEED or WELL certifications. According to the independent research company IDTechEx, the global self-healing materials market will grow significantly from 2025 onward.

Challenges and considerations for adoption

Widespread adoption is not without obstacles. Self-healing alloys and coatings still carry higher material costs, and many are not yet compatible with current forming, welding, or fabrication processes. Also, no unified testing protocol exists for rating self-healing performance under real-world job site conditions. Until the American Society for Testing Materials (ASTM) or the International Organization for Standardization (ISO) codifies new standards, contractors and engineers must rely on pilot data and lab simulations.

Still, early adopters, particularly in infrastructure and coastal development, are pushing forward. The regulatory gap may close quickly as high-profile projects test and validate these materials.

What is next for self-healing metals in construction?

Outside of metals, microbial-assisted materials are blazing a parallel trail. For instance, Delft University of Technology in the Netherlands developed a self-healing concrete system using bacterial spores embedded in biodegradable capsules. Upon contact with water, the bacteria produce calcite that seals cracks. It has already been deployed in tunnels and bridges.

Other “living materials” take it even further. Researchers at Montana State University and other U.S. labs are developing building materials from fungi and mycelium that regrow when damaged, offering a biological analog to metal healing. For the metal industry, these advancements point toward hybrid approaches, integrating coatings, substructures, and intelligent grain boundary engineering into scalable construction systems.

Building toward intelligent resilience

Metal that repairs itself is in the lab and edging into the field. As pressure grows to create safer, more sustainable buildings, self-healing materials offer a compelling path forward. Metal construction professionals should monitor these innovations closely. Those who understand and adopt early will lead the next generation of resilient infrastructure and self-maintaining systems.