Multiple factors affect the design choice for a vented or unvented metal roof. The internal and external temperature and humidity load (driven by climate zone and facility use), roof geometry, installers' skill set and cost are key considerations.

Roof assembly designs are impacted by location, cost and more

Joseph Lstiburek, Ph.D., P.Eng., principal at Westford, Mass.-based Building Science Corp., researches building failures and has authored numerous academic papers related to roof ventilation and other building science topics. Lstiburek says vented and unvented roof designs can be used successfully in all hygrothermal climate zones, but the designs should be climate sensitive. Both design types can address ice dams, moisture accumulation and heat gain, he says.

Defining Unvented Design

Unvented roof designs may be considered in two categories, Lstiburek says: systems where condensing surface temperatures are not controlled and systems where condensing surface temperatures are controlled. The two categories are used in different environments: regions where cold weather conditions occur with enough frequency and intensity that moisture accumulates from the interior on an un-insulated roof deck, which may cause mold, corrosion and decay, and warmer regions. “Your roof is an environmental separator,” Lstiburek says. “It keeps the outside out and the inside in. If the outside is really miserable it’s difficult to do; if the inside is miserable it’s difficult to do.”

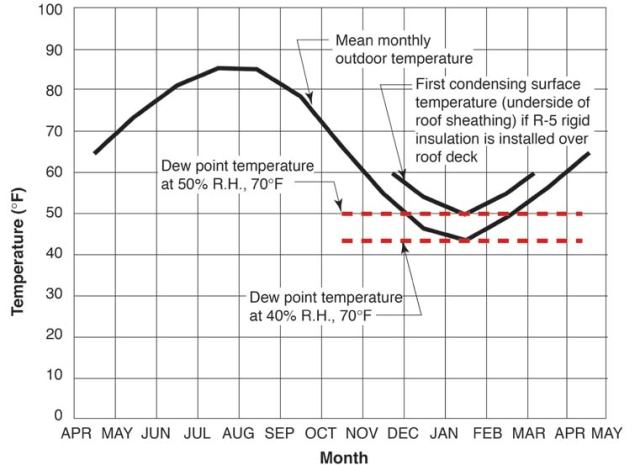

Drawings and graphs copyrighted by Building Science Corp.

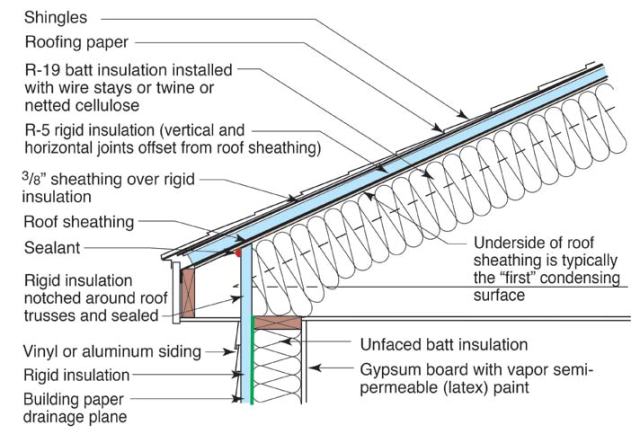

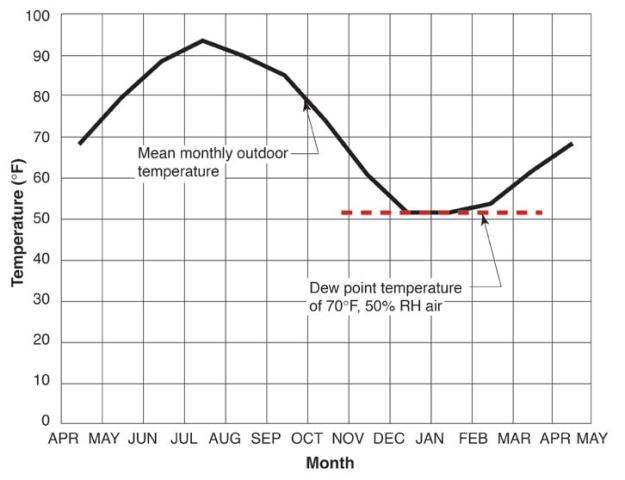

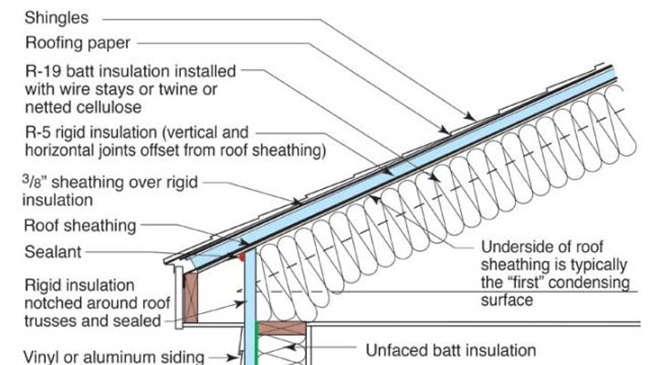

This diagram and graph display the potential for condensation in an unvented roof assembly in Phoenix in which condensing surface temperature (underside of roof sheathing) is not controlled. There is no potential for condensation on the underside of the roof sheathing until interior moisture levels exceed 50 percent relative humidity at 70 degrees F.

Facility uses require different ventilation design choices. Pressurizing and humidifying a building in a cold climate is difficult because moisture and heat are driven into the insulation system where it can end up damaging sheathings and claddings, Lstiburek says. “If you try to enclose a swimming pool in a cold climate and you don’t get the airtightness and vapor-tightness continuous and correct, your building is going to fail,” he says.

Lstiburek says roof assemblies for special-use facilities such as data processing centers, museums and hospitals may require a rigid deck on top of the structure, a fully adhered membrane, rigid insulation and metal roof on top of that, which is expensive. “But the internal load dictates that I have to do that,” he says.

Internal temperature and humidity loads may be broadly grouped in three categories, Lstiburek says. In the first category, temperature is moderated in warehouses and other similar buildings to prevent extreme hot or cold. Interior moisture content or vapor pressure basically track with the exterior environment.

The second category of internal loads is found in buildings with residential and office occupancy. Temperature is controlled precisely; humidity varies in a range, typically 20 percent to 40 percent. “That’s a pretty low load for cold-climate buildings,” Lstiburek says. The third broad category of internal loads pertains to special-use facilities, which need to be humidified and pressurized.

Pros and Cons

Vented roofs are typically the lowest-cost option and are suitable for starter homes and non-custom residential projects, Lstiburek says. They work best with airtight ceiling and attic interfaces, where ductwork and heating, air conditioning and ventilation units are not located in attic spaces. Additionally, vented roof designs are desirable in high snow load areas to control ice damming from snow accumulation.

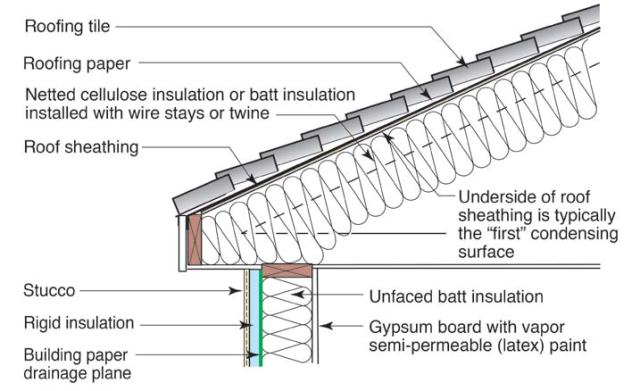

This diagram and graph display the potential for condensation in an unvented roof with insulating sheathing and rigid insulation above the roof deck in Dallas. There is no potential for condensation on the underside of the roof sheathing until interior moisture levels exceed 40 percent relative humidity at 70 degrees F when rigid insulation is not present. Rigid insulation raises the condensation potential above 50 percent relative humidity at 70 degrees F.

Unvented roof designs provide conditioned spaces for ductwork and heating, air conditioning and ventilation units. Various climate locations and internal loads require different designs. Lstiburek says an unvented roof option is preferable in areas exposed to hurricane risk because they don’t leak. “In coastal areas that are prone to hurricanes, 20 to 30 percent of most hurricane water damage is due to wind-driven rain being blown into roof vents,” he says. “There is no such thing as a hurricane-proof roof vent at this particular point in time.”

Additionally, an unvented roof assembly is safer in areas exposed to wildfires. “In high wildfire areas vented roofs are a real problem because of burning embers being pulled into the vent, causing the fires to spread,” Lstiburek says.

Potential Objections

Unvented metal roof assemblies are common on warehouses, factories and shopping malls. Metal cladding manufacturers’ warranties may be unaffected by whether a roof is vented or unvented, as is the case for Bossier City, La.-based McElroy Metal’s warranty. Tommy Johnson, PE, engineering manager at McElroy Metal, says, “Unvented in and of itself does not void warranties, but if the roof is unvented and this causes or allows condensation to occur and corrosion occurs because of the condensation, then it would not be covered under the warranty.”

Lstiburek says whether a roof assembly is vented or unvented does not determine the level of skill required to execute the design. “A vented roof that has a flat ceiling without penetrations, that’s very easy to execute,” he says. “A vented roof with hundreds of penetrations in the ceiling, duct penetrations and service penetrations is very difficult to execute.”

The complexity of a roof’s geometry plays a role in the choice to design it vented or unvented. “As the complexity goes up, unvented technologies or approaches are more practical,” Lstiburek says. “In a high snow load area with a complex roof geometry, you’d have a hybrid. A lower roof is typically constructed in an unvented manner and a vented roof is constructed over top the unvented roof to control ice damming.”

Joseph Lstiburek, Ph.D., P.Eng., principal at Westford, Mass.-based Building Science Corp.

Cost differentiates vented and unvented designs more than installation difficulty. “For example, an unvented panelized system is very easy to execute, but it’s more expensive than an unvented spray-foam system where the spray foam is installed on the underside of the roof deck,” Lstiburek says. “An unvented system where you have a membrane on the top of the roof deck and rigid insulation on the top, that’s very easy to execute, but it’s more expensive.”

Common Failures

Lstiburek says common failures in unvented metal roof designs include seams in insulated metal panels not being sealed correctly and missing air barriers in metal roof panel systems. He says by detailing the air barrier correctly, especially the connection between the roof air barrier and the wall air barrier, designers can ensure an unvented metal roof design is airtight, vapor-tight and functional.

Building failures are typically the result of incorrect specification and faulty installation, Lstiburek says. “You can’t take a product that is unsuitable and expect high-degree, fastidious workmanship to save you,” he says. “You have to match the product to the skill set of the people doing it, to the internal and external environmental load.”