What would you see if you peeked underneath a home’s metal roof, similar to taking the proverbial look under the car hood? Would you see a durable, intact material capable of defending the roof deck and what lies beneath for years to come? Or would it be a compromised, torn material that permits water to infiltrate and damage materials under the metal panels? Chances are good that the view under the roof would be informed by the type of underlayment installed in the metal roof system.

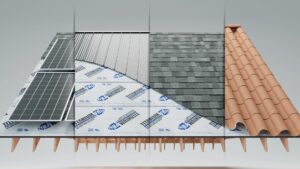

Of course, even with the aid of virtual reality eyewear, it is hardly practical to raise the roof covering once it is installed to determine its condition. Material matters when it comes to protecting the long-term performance of a metal roofing system. From a home’s eaves to its roof peak, underlayment delivers an essential layer of protection intended to perform for the life of the roof. While there are many underlayment materials in the market, choosing a synthetic or self-adhered underlayment is a good starting point.

Synthetic underlayments are more durable than asphalt-saturated felt underlayment materials (sometimes called organic felt) and provide enhanced protection against degradation that can occur when materials are exposed to UV rays. Similarly, synthetic underlayments are designed to help keep moisture away from the roof deck, where favorable conditions may allow mold to form.

Synthetic underlayments offer benefits that go beyond keeping nature’s elements out. In addition to helping to create a water-shedding barrier, they can also help support worker safety on the rooftop.

Self-adhered underlayments have all the benefits of synthetic underlayments with the added benefit of asphalt and rubber polymer adhesives, making them a waterproof solution for the roof deck. Self-adhered underlayment is designed to protect the roof from damage in vulnerable areas where water tends to collect or where penetrations in the roof deck exist.

Given the role that the underlayment plays in supporting a roof’s enduring performance from installation throughout its service life, asking the following questions can help contractors select an underlayment to protect metal roofs for the long haul.

Here are five questions to consider:

How durable is the material?

An underlayment material must be able to stand up to foot traffic on the roof during installation, maintenance, and inspections, as well as handling the load of equipment and tools that may be on the roof. The metal roof installation process typically involves moving panels about on the home’s roof surface, which can create opportunities for the underlayment to tear. The integrity of the material is essential because even very small penetrations in the roof’s underlayment can allow for water to enter. Moisture is not the only threat to a home’s roof. UV rays can degrade materials in the wood deck, especially after sustained exposure. Selecting a material that can withstand exposure to moisture and UV rays can help support durability. For example, synthetic underlayments are manufactured to help protect against UV exposure for up to six months.1 Additionally, these underlayments are up to 12 times stronger than #30 felt underlayment.1

How does the underlayment’s walkability support the contractor’s safety culture?

Steep slopes can present challenges to a roof’s walkability. Worker safety should always be a priority, and the choice of underlayment can complement a holistic approach to keeping workers safe on the roof, even steep-slope roofs. Selecting an underlayment with safety features integrated into the design can contribute to contractors’ safety culture. For example, the walking surface on Titanium’s synthetic and self-adhered underlayments provides a slip-resistant walking experience.

Is the underlayment high-temperature rated?

Extreme heat seems to be occurring more frequently in many regions. NASA confirmed that 2024 was Earth’s warmest year on record, and the National Oceanic and Atmospheric Administration (NOAA) reported that intense heat broke many records across the United States in 2024.2,3

The surface temperature on a metal roof can exceed 140°F on a summer day, and a higher heat load causes materials under the roof to break down more quickly. Checking the temperature rating of an underlayment material helps ensure it is rated to take the heat for years to come. High temperature-rated underlayments are designed to withstand temperatures up to 240°F. The underlayments are engineered to lay flat and not wrinkle when exposed to temperature fluctuations.

What is the span of protection?

There are multiple points of entry when it comes to moisture intrusion through the roof. Season after season, a home’s roof is exposed to moisture entering through compromised flashing, damage caused by ice dams, or condensation occurring under the metal panels. At some point, water is likely to find a way into a home. While building codes in some regions require self-adhered underlayment at eaves, it may also be recommended on rakes, valleys, penetrations, and any area where large amounts of water may collect, and some installers choose self-adhered products for the entire roof deck to prevent water intrusion. Self-adhering underlayments offer a peel-and-stick way to efficiently cover all these areas.

What is the underlayment’s fire resistance?

Recent wildfires in many parts of the United States underscore the importance of fire resistance and the attention that code bodies place on selecting materials used in the Wildland Urban Interface (WUI). When it comes to testing for fire resistance, it is important to keep in mind that roofs are tested as assemblies, and the roof assembly is evaluated according to its ability to resist external fire. The three classifications described in ASTM E108-20a, Standard Test Methods for Fire Tests of Roof Coverings, are as follows:

- Class A tests are applicable to roof assemblies that are expected to be effective against severe fire exposure, afford a high degree of fire protection to the roof deck, not slip from position, and not present a flying brand hazard.

- Class B tests are applicable to roof assemblies that are expected to be effective against moderate fire exposure, afford a moderate degree of fire protection of the roof deck, not slip from position, and not present a flying brand hazard.

- Class C tests are applicable to roof assemblies that are effective against light exposure, afford a light degree of protection to the roof deck, do not slip from position, and do not present a flying brand hazard.

Titanium FR self-adhering underlayment, as part of the roof assembly, meets Class A fire resistance requirements and WUI standards even when installed under metal panels. The proprietary formulation helps mitigate fire spread to the roof deck.

1 Owens Corning Roofing. (n.d.). Titanium® UDL25, UDL30, & UDL50: Synthetic Roofing Underlayment. Owens Corning. https://www.owenscorning.com/en-us/roofing/components/products/titanium-udl

2 Bardan, Roxana. (2025, January). Temperatures Rising: NASA Confirms 2024 Warmest Year on Record. NASA. https://www.nasa.gov/news-release/temperatures-rising-nasa-confirms-2024-warmest-year-on-record/

3 National Oceanic and Atmospheric Administration. (2024, September).U.S. sweltered through its 4th-hottest summer on record. https://www.noaa.gov/news/us-sweltered-through-its-4th-hottest-summer-on-record

Torre Palermino is the self-adhered product leader for Owens Corning, a world leader in building products. She is responsible for driving market and product development activities for residential steep slope applications in North America across all roof claddings.