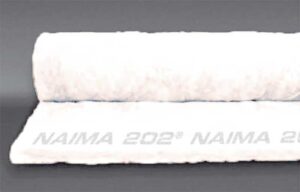

When it comes to metal building insulation, not all products are created equal. This is especially true for laminated fiberglass, which undergoes processing that can affect its thickness recovery and effectiveness. Unless the insulation option has NAIMA 202 printed on the roll of fiberglass, it is not North American Insulation Manufacturers Association (NAIMA) certified, and thus may not recover to its stated R-value after lamination.

Contractors need to know metal building insulation standards so they can ensure they receive a product that is 100 percent of the advertised R-value.

Industry standards

NAIMA 202 Certified Fiberglass Metal Building Insulation

NAIMA is a trade association of fiberglass, slag wool, and rock wool insulation product manufacturers. It aims to promote environmental preservation and reduce energy consumption through these insulation methods, encouraging the safe manufacturing and use of materials.

This particular metal building insulation is specifically manufactured and marketed for the metal building market. For a product to be NAIMA 202 certified, it must meet the standards outlined regarding surface burning characteristics, fungi resistance, thickness, and other product attributes. These regulations help distinguish fiberglass insulation installed in metal buildings from those designed for other applications.

Fiberglass that is certified should be tested in accordance with ASTM E84, CAN/ULC S102, or UL 723. This NAIMA 202 standard should be used to describe and measure the properties of products, materials, or assemblies in response to flame and heat under controlled laboratory conditions. Products should have a flame spread index of no more than 25 and a smoke developed index no greater than 50. NAIMA 202 Certified Fiberglass is required to meet the NIA Certified Faced Insulation standard.

NIA Certified Faced Insulation

The NIA standard “is a post-lamination certification for flexible faced fiberglass insulation used in metal buildings. It was developed by the National Insulation Association (NIA) to assure building owners and builders that the fiberglass insulation fully meets the stated R-value following lamination.”

This standard was developed since the lamination stage of applying fiberglass facing and adhesives can impact the insulation’s thickness recovery and, subsequently, its effectiveness. The NIA Certified Faced Insulation standard addresses quality issues like packaging, handling, storage, compression ratios, adhesive rates, and other factors affecting thickness recovery and thermal performance. It is a standard product specification for use by laminators of metal building insulation systems. The NIA standard was updated in 2022 to include surface burning characteristics (Sections 5.3 and 5.3.1), which require independent third-party testing (Section 11.2). These standards ensure contractors and building owners receive post-laminated insulation that achieves the true R-value advertised—nothing less.

Insulation testing protocols

Samples of insulation are tested quarterly by a nationally recognized independent laboratory and determined to meet the stated requirements of the NAIMA 202 standard. Fiberglass manufacturers pledge that their products have been produced to the same standard as samples tested. Instructions for sampling and inspection can be found in Sections 8.0 and 9.0 of the NAIMA 202 standard.

Tests are conducted in accordance with the American Society for Testing and Materials (ASTM) methods on factors affecting thermal performance, such as thermal resistance and thickness. They measure the length, width, weight, thermal conductivity, and thickness of each product. Furthermore, Underwriters Laboratories (UL) performs additional testing according to ASTM requirements for corrosiveness, fire hazard classification, odor emission, and water vapor sorption.

For insulation to be certified to the NIA Certified Faced Insulation standard, laminators are required to participate in third-party testing by a nationally recognized independent laboratory such as Home Innovation Research Labs. The testing ensures out-of-the-package performance of the insulation and provides assurance that the product delivers the specified insulation R-value.

Ensure it is NAIMA 202 certified

NAIMA 202 Certified Fiberglass Metal Building Insulation is clearly identified with the following permanent markings on the insulation: manufacturer and/or product name, NAIMA 202® (including the registered symbol), and the appropriate R-value.

Products that do not meet the NAIMA 202 certification requirements likely will not deliver the specified thermal performance or recover to the stated R-value post-lamination, which could lead to condensation issues and higher utility bills.

Rick Bachman, district manager of Therm-All, is a 38-year veteran of the metal building industry and has been with Therm-All for 27 years.