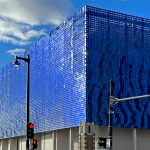

Photo: Brad Feinknopf

Chilled Water Plant 3 at Ohio University is located on a prominent site between campus and athletic fields with visibility by members of the university and an adjacent residential neighborhood. Leers Weinzapfel Associates specified insulated metal panels (IMPs) and curtainwalls to create a design that connects the building to nearby architecture and meets functionality requirements.

Jane Weinzapfel, FAIA, principal at Leers Weinzapfel Associates, says, “The plan building’s straightforward rectangular form and copper-colored insulated metal panel system blends with the neighborhood context in height, color and alignment. Two copper-colored colors and two textures of the metal panel system animate the exterior. Aluminum curtainwall including glass with opaque ceramic frit or clear glass on each elevation is inset to relieve the flatness of the panel system. The interior workspaces are thus all infused with natural light for workplace safety and well-being. Rooftop perforated screening gives additional dimensional interest and proportional balance to the facility.”

To build it, Kingspan Insulated Panels Inc. supplied IMPs in three colors. Wall panels are Bright Copper Metallic and custom Dark Copper Metallic. Rooftop sound enclosure walls are Medium Gray.

The water plant has a 10,900-square-foot main floor and mezzanine that is air conditioned. Below, there is a 12,100-square-foot lower level with ventilation and, on the rooftop, 10,900 square feet with mechanical equipment.

“For resiliency, the main equipment floor is raised about 9 feet above the floodplain; this also allows an efficient ventilation system for the main floor,” Weinzapfel says. “A ramp provides vehicular access to the elevated main floor, and glazed bifold doors allow chiller maintenance and installation of future large equipment at the main level. An effective insulated metal panel acoustical sound wall with screened enclosure at the roof provides noise protection for nearby residential complexes, and rooftop cooling towers were selected to minimize plume issues.”

The chilled water plant adds as much as 7,500 tons of chilled water capacity on the campus. It provides electrical circuitry and a switchgear for a looped electric service and feed point.

“The facility design provides an economical building aesthetic, and addresses environmental issues such as potential flooding, noise and plume factors, while increasing resiliency,” Weinzapfel says.