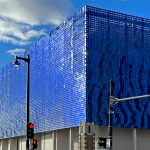

Nobel Halls, Stony Brook University, Long Island, N.Y.

As part of The State University of New York, Stony Brook University on Long Island’s north shore, is part of the nation’s largest and most comprehensive state university system. Both budget and time constraints played important roles in the architectural design for new residence halls that were required to meet the needs of the university’s fast-growing student population.

“The university needed buildings that could be constructed fast and inexpensively,” says F. Eric Goshow, AIA, LEED AP, partner, Goshow Architects. “We wanted to build with pre-fabricated elements to beat the clock … Metal panel systems have been a great favorite of ours. They establish a bright and clean look for buildings.”

“The university needed buildings that could be constructed fast and inexpensively,” says F. Eric Goshow, AIA, LEED AP, partner, Goshow Architects. “We wanted to build with pre-fabricated elements to beat the clock … Metal panel systems have been a great favorite of ours. They establish a bright and clean look for buildings.”

Alucobond Plus aluminum composite material by 3A Composites USA Inc. were ordered in bold colors and installed as exterior cladding on an interconnected series of three buildings totaling 173,000 square feet with varying heights of two to six stories to create architectural interest.

Included in the $56 million project are two new student residences known as the Nobel Halls and named after Nobel Prize-winners C.N. Yang and Paul Lauterbur, both former Stony Brook faculty members. The 604-bed Nobel Halls, which welcomed their first student residents in August 2010, are divided into 104 suite-style apartments featuring a living room, bathroom and three double bedrooms (the latter serving as single bedrooms for resident managers). Adjacent to the two attached residence halls is the Center for Global Studies and Human Development, which provides multipurpose spaces and a café area.

Approximately 100,000 square feet of 4-mmthick Alucobond Plus was installed on the building in a wide range of colors, including: 25,300 square feet of custom Birch; 7,300 square feet of Flag Red; 16,800 square feet of custom SUNY Orange; 30,300 square feet of Bone White; 15,300 square feet of custom Arabian Blue; and 5,000 square feet of Cadet Gray. The Alucobond Plus colors were chosen to serve not only as building identifiers, but as a way to brighten the campus, according to Goshow, who said his firm interviewed Stony Brook students prior to designing the buildings and learned that they thought the campus looked “too brown” in the wintertime.

“We believe in the use of color,” says Goshow. “Color helps to brighten the whole experience. Additionally, we designed the buildings with lots of windows and translucent glazing to provide the interiors with natural daylight and so the buildings could serve as way-finding lanterns at night.”

The contemporary Alucobond Plus material in bold colors helps to make these buildings stand out on the 1,000-acre campus, most of which was built in the 1960s and 70s. In particular, nearby residence halls were designed in the “brutalist” architectural style featuring poured concrete and brick, as well as pitched roofing. Initially, university officials requested that the new residence halls match that style.

“We convinced the university that they couldn’t build traditionally; bricks are labor-intensive and not cost-effective,” says Goshow. “We also wanted to focus on building for the 21st century. It was the perfect time because we had a new university president-Samuel L. Stanley Jr., M.D.-coming on board. And, we wanted to reflect Stony Brook’s academic programs, which have huge emphases on science and technology as well as sustainability. We wanted to distinguish ourselves from the old and look toward the future with confidence.”

The building project is registered under the U.S. Green Building Council’s LEED program. At a minimum, it was required to achieve LEED Silver certification but instead was designed and currently is being submitted for LEED Gold certification, according to Amanda Langweil, AIA, LEED AP BD+C, CSI, CDT, director of sustainability, Goshow Architects, who said installation of the Alucobond backed by insulation outboard of studs played an important role in meeting guidelines for a higher level of LEED certification.

The building project is registered under the U.S. Green Building Council’s LEED program. At a minimum, it was required to achieve LEED Silver certification but instead was designed and currently is being submitted for LEED Gold certification, according to Amanda Langweil, AIA, LEED AP BD+C, CSI, CDT, director of sustainability, Goshow Architects, who said installation of the Alucobond backed by insulation outboard of studs played an important role in meeting guidelines for a higher level of LEED certification.

“This project was unique in that the thermal insulation was mounted to the exterior of the metal studs rather than in between the studs to achieve better thermal efficiency,” according to Mike Dell’Olio, vice president, Kenneth J. Herman Inc., the fabricator and installer, who said the Alucobond Plus panels were installed in a rout-and- return dry-seal curtainwall system that is fully guttered and weeped.

Another unique unique project challenge involved creating the geometric shapes included in the architectural design of the Center for GlobalStudies and Human Development, which was clad in Alucobond Plus in Flag Red.

“The walls of this center are inward sloping on certain elevations and transition to vertical; and, there are numerous window return conditions on the entire project,” says Dell’Olio “This design required unique panel shapes that could only be accomplished with Alucobond. We proposed Alucobond for this project in order to achieve this architectural look without the need for exposed applied trim.”

To meet a fast-approaching move-in deadline for students, Kenneth J. Herman Inc. fabricated the Alucobond panels as they were being installed.

“The project’s timing, creating a new look and beating the budget were key areas of focus for both our architectural and construction teams,” says Goshow.

General contractor: J. Kokolakis Contracting Inc., Bohemia, N.Y.

Architect: Goshow Architects, New York

Fabricator/installer: Kenneth J. Herman Inc., Amityville, N.Y.

Metal wall panels: 3A Composites, Mooresville, N.C., www.alucobondusa.com, Circle #69