Unlike any other metal available for the construction market, coil-anodized aluminum is uniquely suited to exterior architectural applications. Its unmatched durability, extreme lightweight, high strength-to-weight ratio, and easy installation make it a highly functional material, while its 3-D look and ability to be colored to match project needs ensure superior aesthetics. Anodized aluminum can provide the likeness of a number of different metals for architectural applications, but with lower costs and better weathering resistance.

Providing performance durability with installation ease for modern architectural exteriors

Stylish Aesthetics Complement Versatile Function

The coil anodizing process—pioneered by Lorin Industries Inc.—provides the aluminum with a protective layer that improves its aesthetic properties and durability. Continuous coil anodizing forms a clear, translucent oxide layer that protects the metal, shows the metal’s natural beauty, and is consistent over every inch of the aluminum.

The 3-D crystalline structure of the aluminum oxide layer also reflects and refracts light in ways that help the surface come alive. Unlike paints or coatings, this oxide layer is grown from the raw aluminum and bonded at the molecular level so it cannot chip, flake or peel like paints and coatings often do. When metal fines are added to the coil anodizing process, anodized aluminum can be made to match the look of almost any other metal, such as brass, copper, zinc, bronze, gold, silver, stainless steel, titanium or carbon steel. Anodized aluminum, however, does not tarnish like brass, patina like copper, or fade like bronze, so it is UV stable.

Anodized aluminum is as much as two-thirds lighter than other metals. It thus offers a significant cost advantage, as the aluminum itself is often less expensive per square foot than other metals, and far fewer pounds of material are needed for any given application. This not only helps with costs for the anodized aluminum products, but it also contributes to the cost savings for structural aspects of the project. The structure does not need to support significant added weight as in the case of copper, zinc or steel.

Functional Benefits for Architectural Exteriors

The molecular structure of the aluminum oxide layer formed by the coil anodizing process is hard like sapphire, second in hardness only to diamonds. This oxide layer provides long-term durability, as well as corrosion and abrasion resistance. It is also self-healing if damaged as the aluminum will naturally create its own protective oxide layer where it is exposed to the elements.

Anodized aluminum also offers additional benefits for long-term maintenance beyond its unmatched durability. “Unlike paint warranties that require cleaning every year, Lorin’s anodized aluminum only needs to be cleaned every other year if it is on the exterior of a building,” says Phil Pearce, vice president of sales and marketing at Lorin Industries.

Although natural metals are a commodity and therefore prices can have a degree of volatility, generally due to its high strength-to-weight ratio, anodized aluminum can cost much less per square foot than many other natural metals.

Coil anodizing delivers consistent quality, and the handling and installation is simple as the material is light and workable. This solves many challenges faced in construction due to rigid or heavy materials. Many anodized aluminum panels can be installed on buildings with standard hand tools, not requiring the expense of a crane as is the case with other materials.

Anodized Aluminum Applications

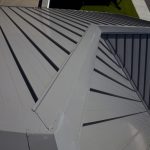

Anodized aluminum can be used for a wide range of architectural and construction applications, including building façades, curtainwalls, roofs, column wraps and lighting. Building façades can be installed as honeycomb panels, ACPs (aluminum composite panels), solid metal panels and rollformed panels. Other common uses include trim, signage and sunscreens. “Lorin’s anodized aluminum products are available with Architectural Class I and II films, and are offered in colors that are UV stable and can be used in coastal areas,” Pearce adds.

With functional benefits of a high strength-to-weight ratio and superior durability, and the aesthetic benefits of a beautiful natural metal look in a variety of colors, anodized aluminum is uniquely suited to bring innovative architecture designs to life for building exteriors.

Steven F. Soderberg is corporate marketing manager at Lorin Industries Inc., Muskegon, Mich. To learn more about anodized aluminum for roofs, visit www.lorin.com.