London’s June 2017 Grenfell Tower Fire was a high-profile tragedy that put fire building safety on the map, and increased public and industry awareness of it. Seventy-two people died in the high-rise fire, including two who later died in the hospital.

In the post-Grenfell world, building fire safety is being reexamined, revised and improved

The 2017 Grenfell Tower Fire.

(Photo courtesy of cc-by-sa/2.0- © Marathon -geograph.org.uk/p/5475737)

The fire was started by a malfunctioning fridge-freezer on the fourth floor. It spread rapidly up the building’s exterior, bringing fire and smoke to all the residential floors. This was due to the building’s aluminum cladding and the external insulation. A cavity between the two formed a chimney and drew the fire upwards in a stack effect. The fire burned for about 60 hours before finally being extinguished.

MagMatrix Perseverance MgO fire-rated structural wallboard meets ASTM E136 noncombustible grade for use in noncombustible construction and is an example of how manufacturers are finding cost-effective structural fire-resistant solutions. (Photo courtesy of MagMatrix Co.)

“This had a significant impact on the industrialized nations worldwide,” says Jonathan Humble, FAIA, NCARB, LEED AP BD+C, regional director of construction codes and standards, American Iron and Steel Institute. “In the United States, all the codes and standards developers who publish national model building and fire codes reviewed their existing regulations and made modifications as necessary based on the Grenfell Tower incident findings and other similar incidents.”

Nestor Iwankiw, PE, SE, Ph.D., of Chicago-based Jensen Hughes, explains, “This tragedy has greatly heightened the understanding, importance and enforcement of the existing building code requirements with regards to control of combustible materials in exterior walls. In particular, compliance with the NFPA 285 standard has been recognized to be critical for preserving fire life safety in this regard.”

John A. Stahl, president of Preferred Solutions, Independence, Ohio, agrees that the Grenfell Tower fire has placed additional emphasis on fire safety of exterior wall assemblies. He cites the development of Annex B to the NFPA 285 standard related to vertical fire propagation of combustible components within exterior wall assemblies as evidence of this.

Staycell ONE STEP Intumescent Spray Foam Insulation helped fireproof this building. (Photo courtesy of Preferred Solutions Inc.)

Stahl explains there are thousands of combinations of building components with exterior wall assemblies and there is the high expense of conducting this NFPA 285 test. Because of this, “It is estimated that more than 90% of wall assemblies constructed in the United States that must comply with NFPA 285 are approved by authorities having jurisdiction and/ or fire marshalls based on engineering judgements written by fire protection engineers and fire protection engineering organizations. Persons writing such engineering judgements have varying knowledge and viewpoints when comparing fire performance characteristics provided by small-scale fire tests to the same small-scale tests as the products that were actually tested in accordance with the NFPA 285 standard. As a result of the need to provide as much guidance and uniformity as possible in writing such engineering judgements, Appendix B is in the process of being added to the next edition of NFPA 285.”

And, Andy Williams, director of codes and standards at the Metal Construction Association, explains that Grenfell was used as an example in a number of code change proposals for recent ICC hearings. “Grenfell has also been used as reasoning behind a number of the code changes in the just-released New York City Building Code.”

Grenfell was a good example that all buildings must meet specific standards for fire safety to function. Keeping a building’s structure updated to fire ratings codes and standards is requisite. What follows are just a few recent updates in fireproofing metal building systems.

Sprayed-applied firestopping products prevent or delay damage to structures exposed to fire. (Photo courtesy of TruTeam)

Six New UL Fire-Resistance Rated Assemblies

In 2021, UL issued six new fire-resistance rated assemblies for wall-roof joints and intersections in metal buildings based on an engineering study sponsored by the Metal Building Manufacturers Association (MBMA). The new UL designs for wall-roof joints between fire-rated assemblies are HWD- 0926, HW-D-0927 and HW-D-0928. For intersections between a fire-rated wall and a non-fire-rated roof, the new UL designs are CJ-D-0029, CJ-D-0030 and CJ-D-0031.

“The new HW-D/CJ-D head-of-wall (HOW) fire-resistant assemblies allow for significantly greater levels of roof insulation to meet more stringent energy code requirements while maintaining fire safety,” explains Vincent E. Sagan, PE, senior staff engineer, MBMA. “The details of the new assemblies are based on and are similar to the other HOW assemblies (HW-D-0488, HWD- 0489, HW-D-0490, CJ-D-0005, CJ-D-0006, and CJ-D-0007). Both sets of designs specify a single layer of glass-fiber blanket insulation compressed between the metal roof panels and the top of an interior wall. The new UL designs allow for additional insulation, glass fiber or mineral wool, between the purlins, as well as a vapor barrier, as found in filled cavity insulation systems and liner insulation systems.”

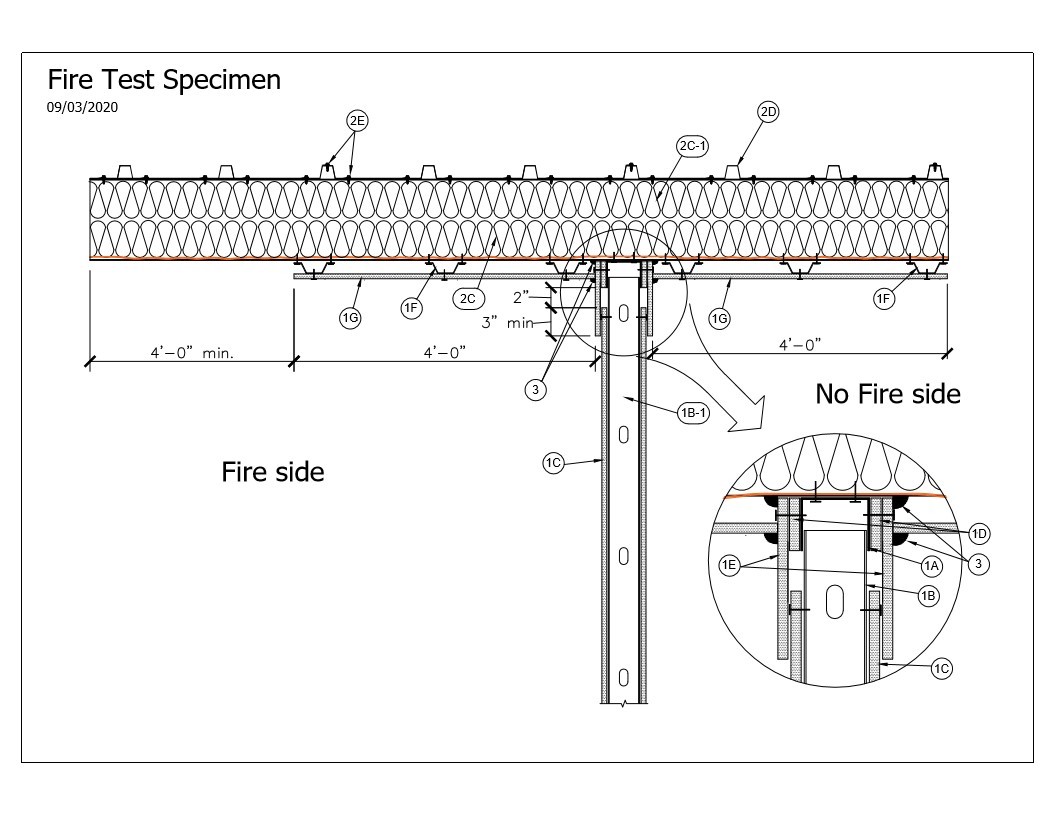

A New HOW Assembly

Also in 2021, MBMA developed a HOW assembly to address the need to accommodate a fully insulated roof purlin cavity without interruption and without requirement to drape and compress the insulation between the purlins and the top of an interior wall. The assembly includes 4-foot-wide gypsum board ceiling membrane protection adjacent to both sides of the wall. The areas between the purlins and above the wall are infilled with glass-fiber insulation.

MBMA’s Fire Resistance Design Guide for Metal Building Systems guide contains the most complete and up-to-date information on the subject of fire resistance for metal building systems. (Photo courtesy of MBMA)

Important Fire Code Updates

Humble explains there are major changes in the 2021 International Building Code, updated Chapter 7 “Fire and Smoke Protection”:

General: Section 703.2, “Fire-Resistance Ratings and Fire Tests,” has included a provision that does not permit the use of a fire suppression system when conducting an ASTM E119 or UL 263 fire endurance test on an assembly.

Structural Steel: Section 704.6.1, “Secondary Attachments to Structural Steel,” is a revised version that expanded the requirements by requiring the same fire protection for secondary structural members to the primary structural components that they are attached to. This provided further guidance as to the intent of the 2018 IBC requirements.

Curtainwalls: Section 715.4, “Exterior Curtain Walls/ Fire-Resistance-Rated Floor Intersections,” was significantly modified to more clearly stipulate the minimum requirements that the void created at the floor/curtainwall intersection.

“Also, American Institute of Steel Construction (AISC) has updated their AISC 360 standard (2022 edition) which includes an updated the Appendix 4 ‘Structural Design for Fire Conditions,’” Humble says. “This chapter contains both a prescriptive and performance methods and brings into the chapter new data from European research and development.”

“For certain occupancies, such as those classified as storing or processing hazardous materials, the International Building Code requires hourly fire resistance ratings in accordance with ASTM E-119 for the primary and secondary members and the roof in metal buildings,” Stahl says. “Unfortunately, no UL Listed Assemblies exist for the roof purlins and through-fastened or standing seam roofs. As a result, fire protection engineers are developing engineering judgements to provide such compliance.”

Iwankiw explains that, “A new provision in the 2021 IBC 704.6.1, which some may not yet be aware of, requires fire protection of a minimum 12-inch-long distance of unrated secondary steel attachments immediately adjacent to steel fire resistance-rated assemblies. This has long been an informal rule of thumb that has been advocated by some companies as good practice, but it has now become a regulatory code requirement. The intent of this requirement is to avoid thermal shorting of the fire resistance-rated assembly during a fire that could overheat the steel, accelerate structural weakening and result in a premature assembly failure.”

Fireproofing testing of assemblies provides invaluable information. (Photo courtesy of MBMA)

As an ACM panel manufacturer, we have seen an influx of performance-related questions and a trend toward specifying products that provide a higher level of performance as it relates to safety in a fire event following each event that made news headlines. The National Fire Protection Agency (NFPA) 285 “Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components” is still the industry standard used today. Passing this stringent test demonstrates the ability of an exterior ACM panel and specific components installed in the system to limit vertical and horizontal flame spread. The key in keeping our buildings safe is to specify and install the specific components approved in the NPFA 285-tested ACM wall assembly, as well as emphasis on implementation and enforcement of building and safety codes.”

Overall, Humble has witnessed a large marketing effort by several agencies and organizations to encourage jurisdictions to update their adopted code to the most recent versions of the national model codes. “This is gaining momentum as a result of the increase in the number and size of recent wildfires, tornados, hurricanes and flooding. Such events are being associated with climate change and sustainability such that the focus of individual subjects has been combined into a holistic approach (e.g., health, safety, welfare, sustainable, resilient, high performance, etc.).”

COVID and Fireproofing Updates

COVID-19 had a worldwide impact on material availability, delivery and shortages. Iwankiw explains there has been a reported supply shortage of some construction and fire protection materials, like mineral wool insulation and gypsum board. Mineral wool has very good noncombustible, fire-resistant properties. Gypsum board is frequently used as a protective barrier to structural elements in metal building designs such as structural steel and cold-formed steel framing. “This situation has caused extended delivery times and search for alternative material/product substitutions in some cases. The need for professional engineering judgments to determine the adequacy of such revised designs or alternative materials for maintaining the code required fire resistance ratings of building construction have accordingly increased.”

Fire Safety Foam Update

As energy codes are requiring reduced air leakage in building envelopes, Stahl explains that foam insulation sprayed on the interior or exterior surface of exterior walls and roofs is increasingly being specified for pre-engineered metal buildings and other building types using single-skin metal panels. “Heretofore spray foam insulation has not always been cost-competitive compared to other insulation products due to building code requirements that foam insulation be covered with fire-protective materials such as fireproofing. Staycell ONE STEP Intumescent Spray Foam Insulation Systems comply with code requirements when installed exposed without fire protective coverings.”

This fire test specimen is part of a new HOW Assembly designed for fireproofing. (Photo courtesy of MBMA)