Perhaps the most vexing problem facing the construction industry over the last two years has been the disruption caused by the supply chain. When the pandemic shut down ports in Asia and the United States, halted over-the-road freight transportation and forced workers to stay at home, the availability of building materials disappeared nearly overnight. Two-and-a-half years after the start of the global shutdown, raw material suppliers, manufacturers and logistics companies are still struggling to get building products to job sites.

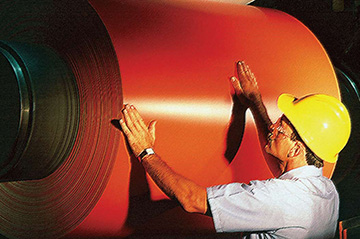

Supply chain disruption and increased demands are causing shortages in some coil coating products

One of the products most acutely affected by the squeeze was coil coatings, and, in particular, polyvinylidene fluoride (PVDF)-coated coils. The squeeze included not just coil coatings, but also extrusion coatings and field-applied coatings.

Narrow Supply Chain

Technical coil coating is a process in which a coating material is applied on the metal strip in a continuous process. The technical coil coating process involves chemical pre-treatment of the metal surface on either one side or both sides. The process is used in more than just construction, though. It also affects transportation, furniture, appliances, etc. And the coating is not just PVDF; it includes polyester, epoxy, acrylic, polyurethane and silicone.

Michelle Vondran is technical manager for NS BlueScope Coated Products–North America, Kalama, Wash., and she explains, “The PVDF resin, created from fluorite and ethylene, is widely used across many industries, including architectural coatings. Applications include batteries and sensors, high-purity semiconductors, filaments for additive manufacturing, biomedical applications and many more.”

Like much of the rest of the building products world, PVDF was affected by the same supply chain issues. “COVID has caused well-known, widespread logistics problems across the globe,” says Paul Lavallee, global marketing manager for Kynar Coatings at King of Prussia, Pa.-based Arkema Inc. “Rolling lockdowns in China continue to cause issues as the global situation has not yet returned to normal. Costs have escalated, being further exacerbated by surging fuel costs and low container and truck availability. This is truly a global challenge affecting not only PVDF availability.”

The World Runs on Batteries

But PVDF has also seen a significant increase in demand, especially from areas that aren’t in the architectural coatings arena, such as batteries, etc. “Many of these applications are growing very fast,” says Lavallee, “thus squeezing available PVDF supply. PVDF suppliers are compelled to make choices in where to allocate their PVDF volumes.”

Richard King, product manager, Steelscape, Kalama, Wash., says, “The primary demand driver for the PVDF resin is lithium-ion batteries. The PVDF resin works as a polymer separator, in which it is the ideal material to manage ion flow while preventing internal short circuits due to its microporous structure. The use of lithium-ion batteries continues to expand. It is not just electric vehicle demand but also batteries for energy storage, such as batteries capturing residential solar energy.

“Demand for lithium-ion batteries is set to expand at an exponential rate, with PVDF resin demand anticipated to expand five-fold between 2021 and 2025. The supply chain is set to improve as battery production is a central focus of national political agenda. However, in the current and foreseeable environment, demand continues to exceed supply, placing supply stress on users of PVDF resins. In many markets, directing PVDF resin output to battery production segments can be more profitable, compounding the issues faced by the architectural coatings industry.”

How Long Can It Last?

Part of the reason for the shortage in architectural coatings is caused by the quality PVDF coatings provide. It is generally more desirable compared to other coatings. The PVDF resin is one of the primary components of a paint system. The others are pigments, solvents and additives, but the resins make up about 30% of the paint composition. PVDF coatings are one of a couple of main kinds of paint systems specified in the architectural coatings market. The others are polyester paints and silicone modified polyesters (SMPs), but generally PVDF is regarded as the best performing. It lasts long, presents a brighter color, resists chalking and fading, and is more durable.

Increased demands are causing shortages in some coil coating products until 2023 or 2024. In the short term, the problem is likely to persist. However, medium- and long-term, it is anticipated to improve as supply chains adapt to the new post-COVID environment and as resin production capacity comes online.

According to King, “Feedback from paint vendors indicates the PVDF resin production capacity is coming online but is unlikely to meet demand and increased demands are causing shortages in some coil coating products until 2023 or 2024. In the short term, the problem is likely to persist. However, medium- and long-term, it is anticipated to improve as supply chains adapt to the new post-covid environment and as resin production capacity comes online.”

Arkema, says Lavallee, has not reduced its supply to the coatings market at all. In that perspective, shortages are caused almost entirely by increased demand in construction, and companies such as Arkema have worked diligently to overcome supply chain issues. “The supply chain issues are persisting,” says Lavallee, “although they appear to be improving over time. Arkema has recently announced a 50% capacity expansion in Asia, which starts-up in late 2022, as well as another 50% capacity expansion in its PVDF plant in France in early 2023. And Arkema continues to study several options for further PVDF capacity expansion.”

It’s the down-the-line effect of the shortage of PVDF resin that everyone feels. “As with all supply chains, material outages can have compounding effects,” says King. “Paint availability can delay the release of metal, metal availability delays the fabrication of products, and this ultimately delays the installation of products at a suitable time. These delays are most pronounced on one-off or custom color projects where the supply chain can’t rely on built-up inventory or the routine flow of inventory supply to smooth product flow.”

Alternative Specifications

He goes on to say that PVDF products with higher pigment loads, such as blacks, can experience greater delays. “Manufacturers may have outages of certain colors,” says King, “which may result in the need to find an alternate supplier, alter the desired color choice or change to a different paint system such as a SMP, super-durable polyester or FEVE paint system. This may result in a trade-off in building design or finish performance.”

Kynar 500 has been around for more than 50 years and proved itself a durable and reliable coating, but no manufacturer sits on its laurels and doesn’t try to improve its product. You never know when a global pandemic will strike and affect supplies, so alternatives are essential beyond the importance of improvement. “We see a strong future for high-durability coatings; a durable society is better than a disposable society,” says Lavallee. “Sustainable cities depend on surface protection that can weather the storm and endure the elements. Less recoating means lower life cycle costs, improved appearance, and lower lifetime VOC emissions.” The development of Kynar Aquatec, a waterborne PVDF, addresses those issues and provides an alternative during times of shortage.

That was a forward-thinking but there is an immediate need for alternatives. In fact, King says, “Long term, the paint manufacturing companies may develop and invest in alternate paint chemistries that provide a broader range of high-performance solutions for architectural coatings and reduce their supply risk. Given the extended warranties and life expectations for high-performance coatings, the development of new products takes considerable time, and any new product is unlikely to be available in the market before 2025.

“PVDF is an excellent architectural coating and offers outstanding performance, including chemical and corrosion resistance. Currently, PVDF systems are the only widely used coil-coated architectural paint system that achieves the stringent AAMA 2605 test requirement while maintaining a lengthy warranty. It is this unmatched performance and warranty coverage that underpins PVDF’s extensive use in commercial projects today. However, polyester and SMP technology has improved significantly. In benign environments, finish integrity and color fade warranties can exceed 40 years for these products. For many project environments the added performance of a PVDF system may be unnecessary and an alternate system may provide sufficient performance.” Faced with delays on a project because of a shortage of PVDF resin, the alternatives are to re-evaluate the need for such a product if the environment of the building will allow for an alternative. If the delay is because the color is custom or requires more PVDF resin, the solution may be to move to a different color.

In the long run, though PVDF coatings are going to continue to be a mainstay of the architectural coatings world and although supplies may be tight for another year or so, there are enough alternative solutions that projects should be able to continue.

The only other alternative is to ask people to stop using smartphones and other products that require lithium-ion batteries so that the construction industry can have more access to PVDF coatings, but that seems like an unlikely solution.