Energy performance requirements for metal buildings have increased substantially over the last 15 years, driving significant changes in insulation system design and installation. Two primary frameworks shape these requirements: the International Energy Conservation Code (IECC) and the ASHRAE 90.1 Standard. Both the IECC and ASHRAE 90.1 have tightened minimum thermal performance values over the last decade, resulting in thicker, higher-performing assemblies becoming the go-to solution for building envelope compliance. Understanding high-R insulation systems helps contractors and erectors avoid compliance issues, ensuring the metal building envelope performs as required.

R-values and U-values

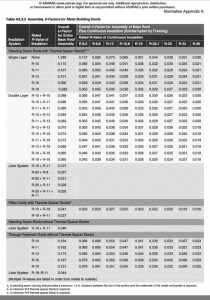

IECC 2012 marked a turning point for metal building insulation because it was the first cycle to introduce significantly higher R-value requirements for both roofs and walls. All required R-values and their corresponding U-values for metal building roofs and walls are listed in ASHRAE 90.1 Tables A2.3.3 (Roofs) and A3.2.3 (Walls). These tables serve as the basis for the IECC and ASHRAE 90.1 compliance options used in every climate zone.

The wall tables are where many crews and designers pause because the requirements sometimes show up as combinations rather than a single number. For example, a climate zone might call for “R-13 + R-13 CI.” That is not one product; it is a system. This indicates that two separate insulation materials should be used together, R-13 fiberglass paired with R-13 rigid board insulation, to meet the required U-value. However, both IECC and ASHRAE 90.1 do allow flexibility through the U-value compliance approach. This means any published system in ASHRAE 90.1, or any proprietary system tested through ASTM C1363 hot box procedures, may be used if its measured U-value meets or exceeds the code requirement.

How the requirements have evolved

From IECC 2012 up to IECC 2024, there have been very few changes to the R-value and U-value tables. From ASHRAE 90.1 2013 up to ASHRAE 90.1 2025, the same is true. Over the years, only minor tweaks have been made to wall requirements. Instead, the major differences have centered on whole-building performance factors, including tighter air leakage control, improved mechanical efficiency, reduced thermal bridging, updated lighting requirements, and more attention to onsite renewable energy. Insulation remains a core part of compliance, but it now operates within a broader energy strategy that encompasses the entire building envelope.

Codes vary by state

Each state follows its own review and adoption cycle, resulting in code versions that can vary. Some states may be using the IECC 2012, while others have adopted the IECC 2021, and these adoptions can change over time. Many states update their codes at the start of the calendar year, but others wait until mid-year, often June or July. For a contractor working across state lines, this means confirming the active code cycle for the project location, as well as monitoring state resources, code council updates, and local regulatory communications. There are also a few states that have their own state-specific energy codes, such as California (Title 24) and Washington (WSEC).

When high-R systems are required

Today, most climate zones require high-R fiberglass systems for metal buildings to meet envelope requirements. However, there are some exceptions. Unheated buildings and low-energy buildings typically have no insulation requirements, while semi-heated buildings have relaxed requirements. Each building type, along with its unique requirements, is defined in both IECC and ASHRAE 90.1.

High-R systems defined

The term “high-R” stands for “high R-value.” At the same time, “system” refers to the combination of materials that comprise the full assembly, such as fiberglass, a vapor retarder, support banding, and screws. There are two main types of high-R fiberglass systems defined in IECC and ASHRAE 90.1: liner systems (LS) and filled cavity systems (FC).

Liner systems are designed for use on both roofs and walls, making them suitable for both new construction and retrofit applications. A typical liner system roof application includes two layers of unfaced fiberglass, a low-permeance fabric that serves as the vapor retarder, and banding that runs both parallel and perpendicular to the purlins. One layer of fiberglass is installed between the purlins, and the second layer is installed over and perpendicular to the purlins. The fabric vapor retarder is attached to and completely covers the bottom of the purlins. Liner systems are usually private-label products, and some variations offer leading-edge fall protection.

Filled cavity systems, which are also referred to as Long Tab Banded systems or High-R Banding systems, are designed for use in metal building roofs only. They are comprised of two layers of fiberglass, one laminated with a vapor retarder and one unfaced, plus banding which runs perpendicular to the purlins. The laminated layer of insulation is installed between and parallel to the purlins, while the unfaced layer of fiberglass is installed on top of and perpendicular to the purlins. Long Tab Banded systems are usually non-proprietary, and the purlins are left exposed.

High-R wall systems may be single-layer or double-layer, depending on the climate zone. Whether in walls or roofs, what ultimately matters is the tested performance of the full assembly. Metal framing and installation details affect heat flow, so tested U-values are used to judge assemblies. For example, a standard R-30 roof liner system yields an in-place U-value of 0.037, corresponding to an overall R-value of approximately R-27.

The type of roof matters

Roof selection also impacts a project’s insulation path. For example, standing seam roofs offer the most options for in-place U-value, whereas screw-down roofs have only one tested U-value (U-0.044), which sometimes does not meet code requirements. This is why roof type is not only a structural decision but also a thermal performance decision made early in the design process.

Beyond fiberglass: Other high-R options

Fiberglass systems are common, but they are not the only route. Insulated metal panels (IMPs) and rigid board insulation are also widely used in metal building applications. Board insulation qualifies as continuous insulation (c.i.) under code definitions, and because it maintains a uniform thickness across framing members, its labeled R-value tracks closely with the in-place performance.

IMPs are a bit more complex. Their seams create small thermal bridges; therefore, IMP assemblies must be tested using ASTM C1363 to confirm their performance. Even with those seams, IMPs generally retain most of their rated thermal value once installed.

Looking ahead

The days of defaulting to 152.4 mm (6 in.) R-19 roof insulation and 101.6 mm (4 in.) of R-13 wall insulation are no longer in place. Today, high-R systems have become the standard in metal building construction, prompting pre-engineered metal building (PEMB) manufacturers to refine components such as flange bracing and eave adaptors to support thicker assemblies. As data centers and other high-demand project types continue to surge, the use of reliable, well-engineered high-R systems will only intensify.

Bill Beals, district manager of Therm-All, is a 40-year veteran of the metal building industry and a contributing member of several committees, including the Metal Building Manufacturers Association (MBMA) Energy Committee and the National Insulation Association (NIA) Laminators Committee. Bill also belongs to the American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) and the International Code Council (ICC). Bill has contributed to over 100 articles and reference guides on commercial energy codes and has instructed AIA-accredited courses for more than eight years. He was inducted into the Metal Construction News Hall of Fame in 2024.